Microfluidic preparation method and application of marine polymer microspheres

A technology of polymer microspheres and polymer solutions, which is applied in the direction of microsphere preparation, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problems of high price, cumbersome process steps, and complicated preparation. , to achieve the effect of low cost, simple process and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

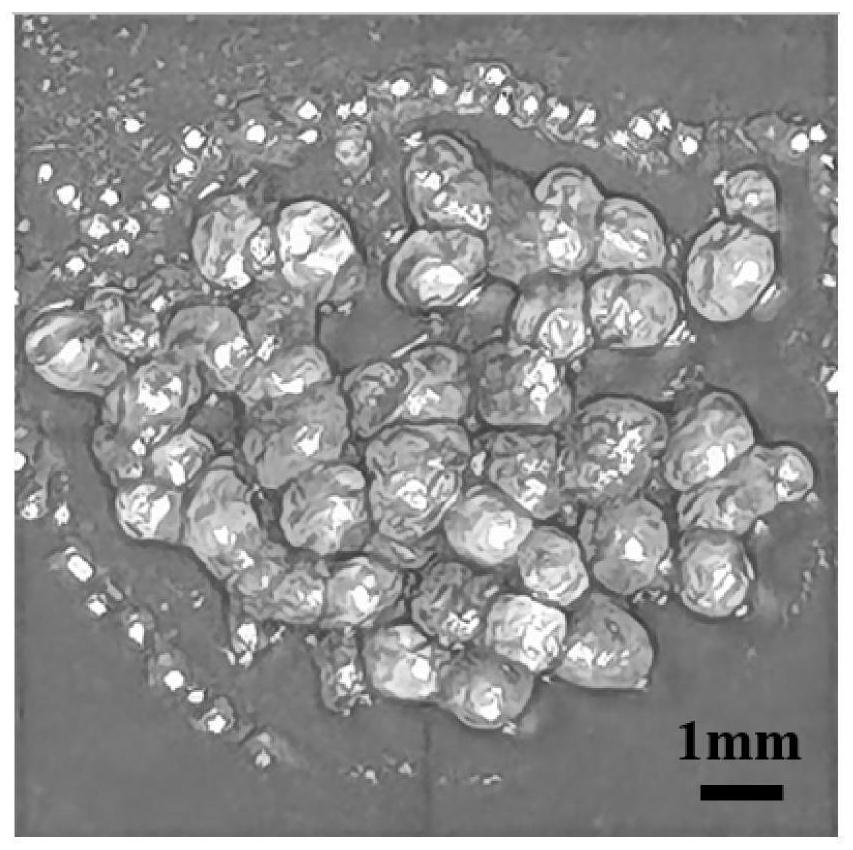

Embodiment 1

[0046] The chitosan is respectively dissolved in 0.5% aqueous solution of hydrochloric acid, sulfuric acid, nitric acid, acetic acid and formic acid to prepare a solution with a mass concentration of chitosan of 1%. The obtained chitosan solution is used as the internal phase, isobutanol is selected as the external phase, and the isobutanol solution of 1% NaOH is used as the receiving liquid. In the microfluidic system, the above-mentioned chitosan solution was input into a capillary with an outlet diameter of 100 μm through a pressure pump, and its flow rate in the microfluidic system was adjusted to 1 mL / h. The external phase was also input through a pressure pump at a flow rate of 100mL / h; under the shear action of the external phase, the internal phase forms independent spherical micro-droplets, which are carried into the receiving liquid with the external phase. After about 10 minutes, spherical chitosan microspheres can be solidified to obtain spherical chitosan microsphe...

Embodiment 2

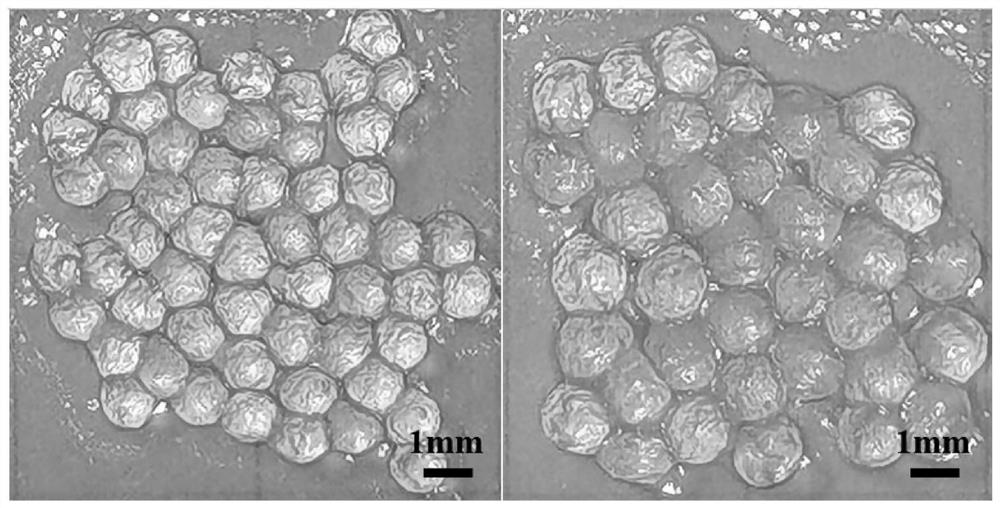

[0047] Embodiment 2 (lower limit of chitosan concentration, lower limit of alkali concentration)

[0048] Chitosan was dissolved in 0.5% acetic acid aqueous solution to prepare a chitosan solution with a mass concentration of 0.3%. The obtained chitosan solution was used as the internal phase, isoamyl alcohol was selected as the external phase, and the isobutanol solution of NaOH with a mass concentration of 0.1% was used as the receiving liquid. In the microfluidic system, the above-mentioned chitosan solution was input into a capillary with an outlet diameter of 100 μm through a pressure pump, and its flow rate in the microfluidic system was adjusted to 4 mL / h, and the external phase was also input through a pressure pump with a flow rate of 120 mL. / h; under the shear action of the external phase, the internal phase forms independent spherical micro-droplets, which are carried into the receiving solution with the external phase, and can be solidified to obtain chitosan micr...

Embodiment 3

[0049] Embodiment 3 (mixed acid, flow rate ratio lower limit)

[0050] Prepare 1% acetic acid aqueous solution and 0.5% nitric acid aqueous solution. Mix the two solutions in equal volumes to prepare a mixed acidic solution, and use the mixed solution as a solvent to dissolve chitosan to prepare a solution with a mass concentration of chitosan of 1.0%. The obtained chitosan solution is used as the inner phase, isoamyl alcohol is selected as the outer phase, and the isoamyl alcohol solution of 1.0% NaOH is used as the receiving liquid. In the microfluidic system, the above-mentioned chitosan solution was input into a capillary with an outlet diameter of 100 μm through a pressure pump, and its flow rate in the microfluidic system was adjusted to 4mL / h. The external phase was also input through a pressure pump at a flow rate of 120mL / h; under the shearing action of the external phase, the internal phase forms independent spherical micro-droplets, which are carried into the recei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com