Integrated Fabry-Perot MEMS acceleration sensitive chip processing method

A technology for sensitive chips and processing methods, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as damage and deformation of sensitive chips, and achieve the effects of ensuring consistency, high parallelism, and low difficulty in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other implementations obtained by persons of ordinary skill in the art without making creative efforts fall within the protection scope of the present invention.

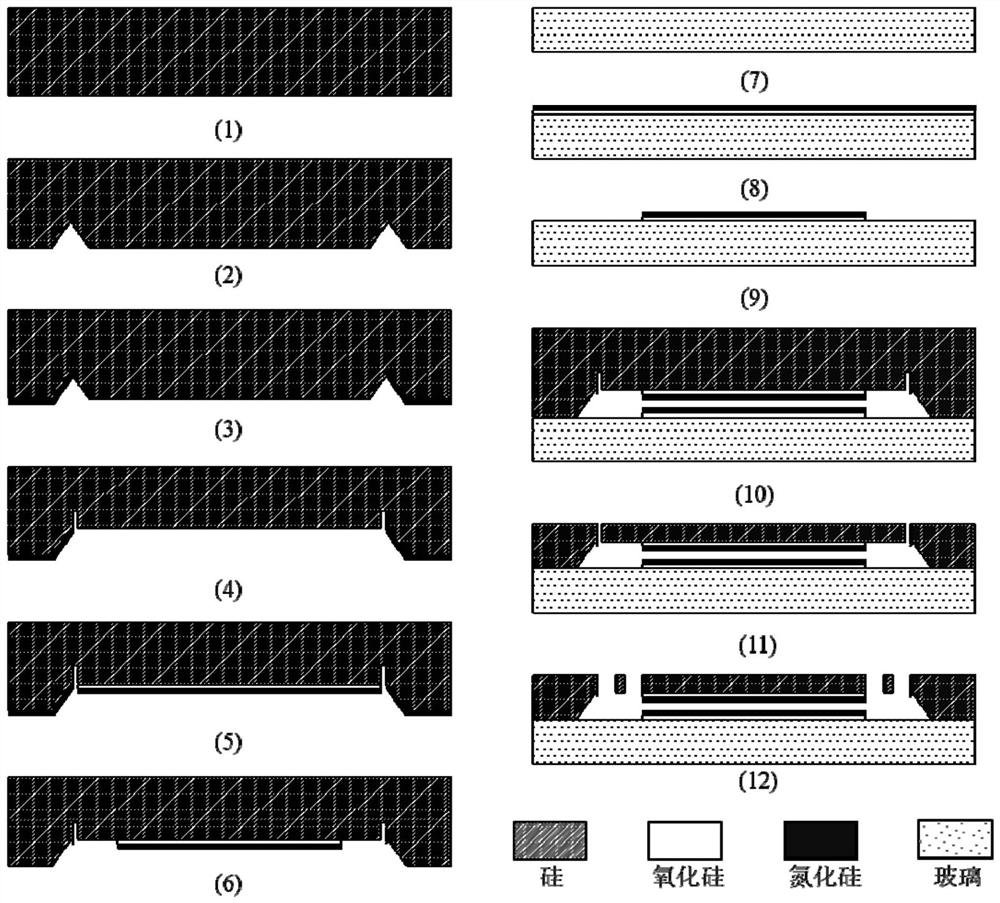

[0033] The following is combined with specific figure 1 The technical solution of the present invention is described in detail.

[0034] (1) Prepare a silicon wafer, first immerse it in acetone and alcohol solution for cleaning, and then immerse it in a solution of sulfuric acid / hydrogen peroxide for cleaning to remove oxide film, metal ions and other impurities.

[0035] (2) Utilizing the anisotropic wet etching technology of silicon to etch the silicon wafer cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com