Epoxy resin-based high-bending-modulus polydicyclopentadiene and preparation method thereof

A technology of polydicyclopentadiene and dicyclopentadiene, which is applied in the field of epoxy resin-based high flexural modulus polydicyclopentadiene and its preparation, can solve problems such as environmental pollution and waste of resources, and achieve improved flexural modulus , combined with the effect of stability and good fitting space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

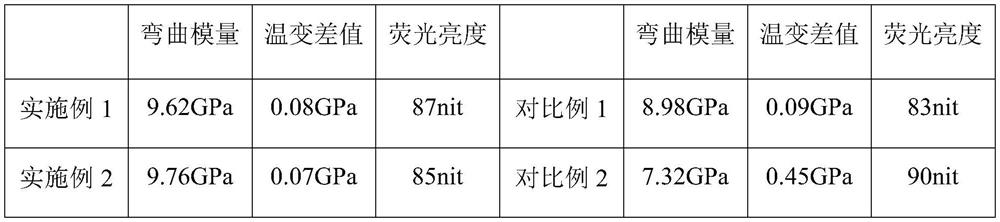

Embodiment 1

[0032] An epoxy resin-based high flexural modulus polydicyclopentadiene, mainly comprising: 60 parts of tetradentate helicoids, 20 parts of p-dicyclopentadiene, 20 parts of 4-vinylpyridine, 100 parts of cyclopentadiene in parts by weight Oxygen resin, 5 parts neodymium chloride and 2 parts ethylenediamine.

[0033] A kind of preparation method of epoxy resin base high flexural modulus polydicyclopentadiene, the preparation method of described epoxy resin base high flexural modulus polydicyclopentadiene mainly comprises following preparation steps:

[0034](1) Primary molecular assembly: Mix pyrrole, p-hydroxybenzaldehyde, triethyl acetate and dichloromethane in a mass ratio of 1:2:2:5, then add boron trifluoride 0.05 times the mass of pyrrole, and In the atmosphere, react at 40°C for 60 minutes, then add chlorop-benzoquinone 5 times the mass of pyrrole, reflux at 60°C for 5 hours, keep the reflux temperature for 8 minutes, cool to -10°C to crystallize and filter, and wash with...

Embodiment 2

[0038] An epoxy resin-based high flexural modulus polydicyclopentadiene, mainly comprising: 80 parts of tetradentate helicoids, 23 parts of p-dicyclopentadiene, 23 parts of 4-vinylpyridine, 120 parts of cyclopentadiene in parts by weight. Oxygen resin, 7 parts neodymium chloride and 3 parts ethylenediamine.

[0039] A kind of preparation method of epoxy resin base high flexural modulus polydicyclopentadiene, the preparation method of described epoxy resin base high flexural modulus polydicyclopentadiene mainly comprises following preparation steps:

[0040] (1) Primary molecular assembly: Mix pyrrole, p-hydroxybenzaldehyde, triethyl acetate and dichloromethane in a mass ratio of 1:2:3:6, then add boron trifluoride 0.08 times the mass of pyrrole, and In the atmosphere, react at 45°C for 70 minutes, then add chlorop-benzoquinone which is 8 times the mass of pyrrole, reflux at 70°C for 4 hours, keep the reflux temperature and concentrate for 9 minutes, cool to -15°C to crystalliz...

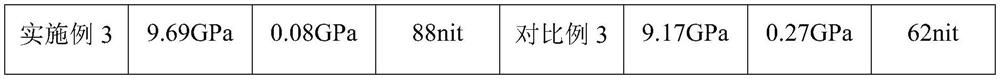

Embodiment 3

[0044] An epoxy resin-based high flexural modulus polydicyclopentadiene, mainly comprising: 100 parts of tetradentate helicoids, 25 parts of p-dicyclopentadiene, 25 parts of 4-vinylpyridine, 140 parts of cyclopentadiene in parts by weight. Oxygen resin, 10 parts neodymium chloride and 4 parts ethylenediamine.

[0045] A kind of preparation method of epoxy resin base high flexural modulus polydicyclopentadiene, the preparation method of described epoxy resin base high flexural modulus polydicyclopentadiene mainly comprises following preparation steps:

[0046] (1) Primary molecular assembly: Mix pyrrole, p-hydroxybenzaldehyde, triethyl acetate and dichloromethane in a mass ratio of 1:2:3:7, then add boron trifluoride 0.1 times the mass of pyrrole, in nitrogen In the atmosphere, react at 50°C for 60 minutes, then add chlorop-benzoquinone 10 times the mass of pyrrole, reflux at 80°C for 3 hours, keep the reflux temperature and concentrate for 8 minutes, cool to -10°C to crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com