Test process of nitrile additive applied to lithium cobalt oxide system electrolyte

An electrolyte and lithium cobalt oxide technology, which is applied in the field of lithium-ion batteries, can solve problems such as instability, easy oxidation and decomposition, and battery capacity attenuation, and achieve the effects of improving the testing process and testing efficiency, excellent performance, and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

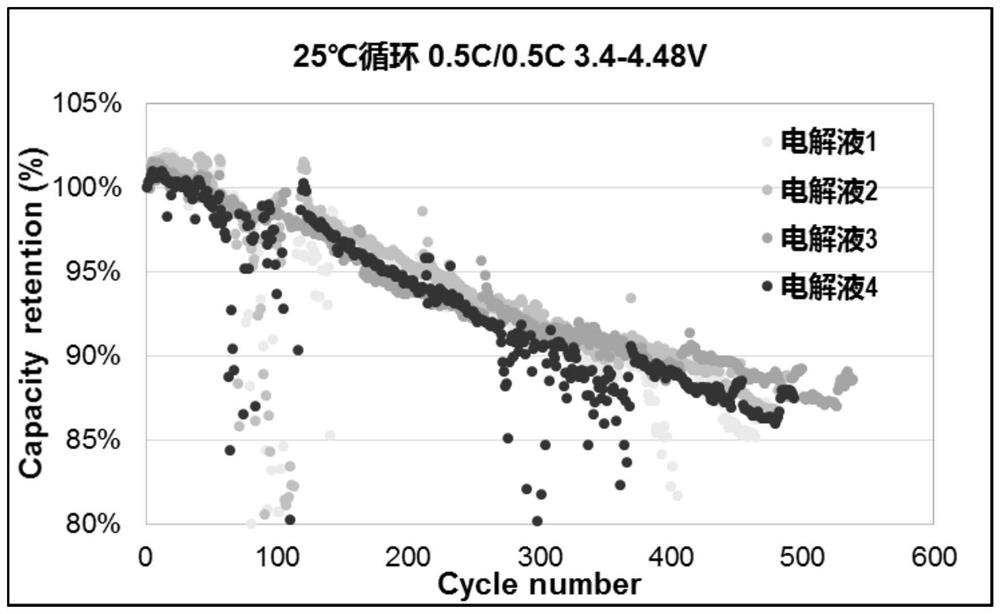

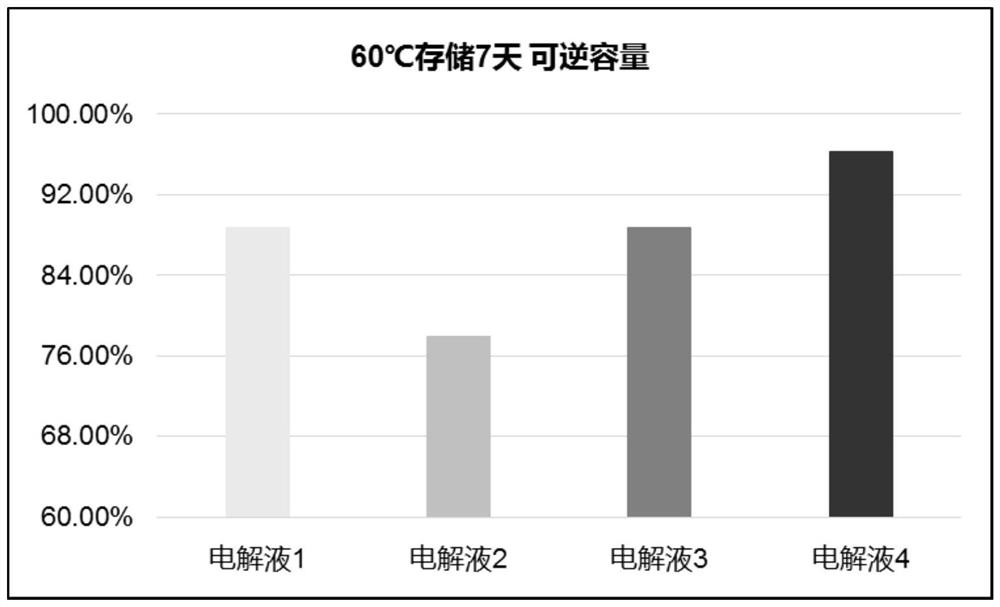

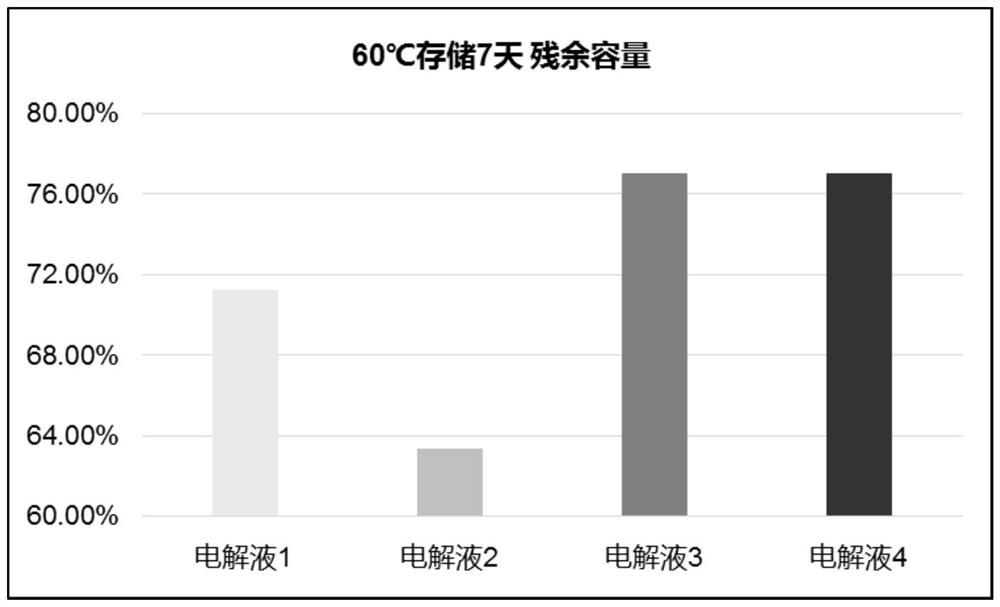

[0026] Such as Figure 1 to Figure 8 As shown, a test process for nitrile additives applied to the lithium cobaltate system electrolyte, including the preparation process of the soft pack cell:

[0027] Step 1: adding 98% LCO positive electrode material, conductive agent, binder, NMP and other substances into the stirring device 10 according to a certain mass ratio, and then stirring at a high speed to make positive electrode slurry;

[0028] Step 2: Coating the positive electrode slurry described in step 1 on the aluminum foil, then baking, rolling, and cutting into pieces to make positive electrode sheets;

[0029] Step 3: add graphite with a mass ratio of 97%, conductive agent, adhesive, thickener, softener, deionized water and other substance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com