High-voltage electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve problems such as unsatisfactory comprehensive effects, and achieve effects suitable for industrialization promotion and application, improving composition, and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

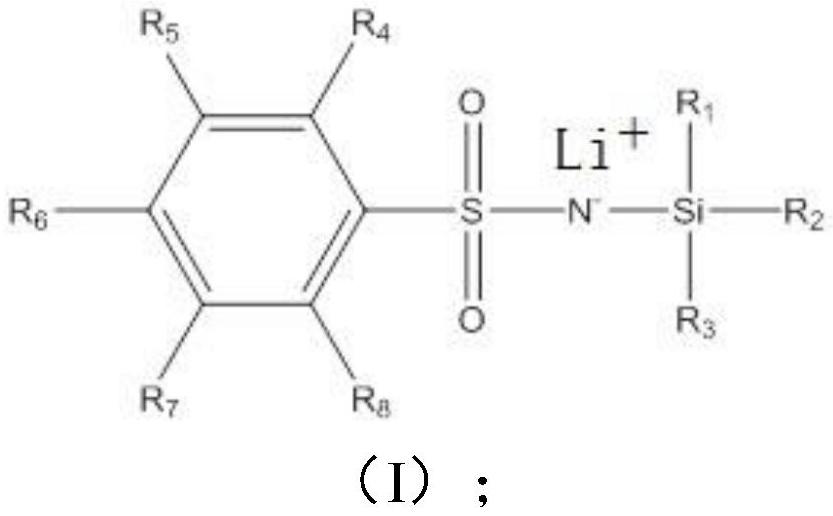

Method used

Image

Examples

preparation example Construction

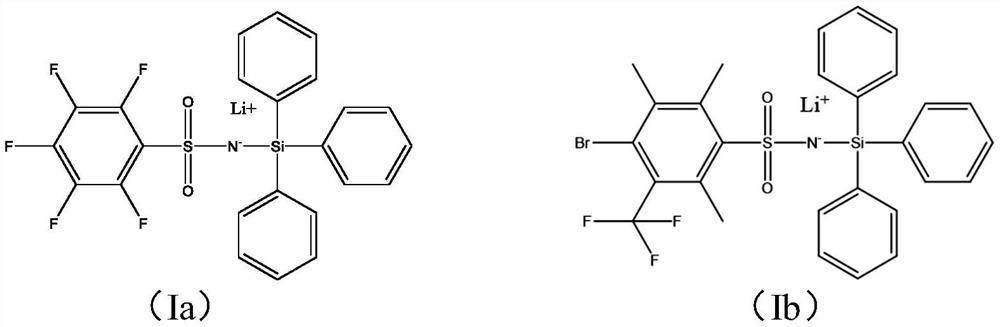

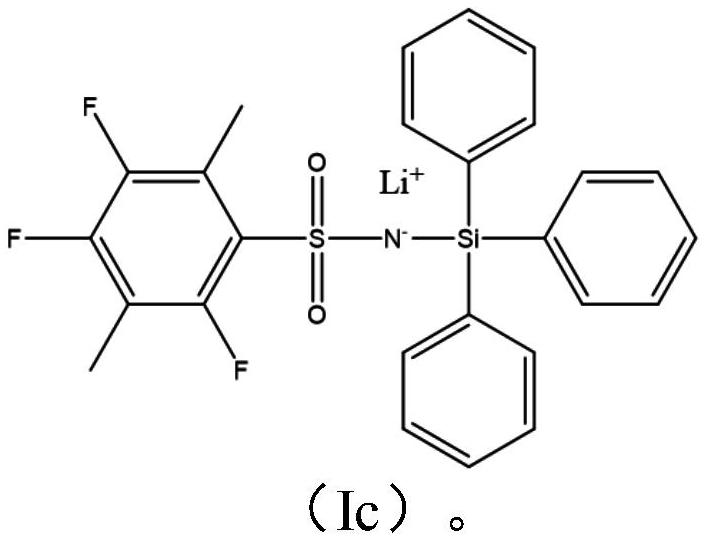

[0075] Preparation of film-forming additives:

[0076] Under the condition of nitrogen protection, the whole reaction system was added dichloromethane, triethylamine, and triphenylsilylamine into a three-necked flask with a constant pressure dropping funnel at -30C° and kept stirring for 1 to 3 hours. . The methylene chloride solution of 2-(trifluoromethoxy)benzenesulfonyl chloride was slowly added under stirring, and the reaction was continued at low temperature for 12 hours. After the reaction, use NaHCO 3 The saturated solution was extracted three times, the organic layers were combined, and washed with anhydrous Na 2 SO 4 Dry, filter, and rotary evaporate under reduced pressure to obtain the prepared silamide ligand. Then the n-butyllithium solution was slowly added at -80°C, and the reaction was continued for 4-8 hours under low temperature, anhydrous and oxygen-free conditions. After the reaction is completed, the temperature is slowly returned to room temperature t...

Embodiment 1

[0079] Mix EC (ethylene carbonate): DMC (dimethyl carbonate): EMC (ethyl methyl carbonate) in a ratio of 4:2:4 in a glove box with water content and oxygen content less than 0.1 ppm. Add a certain mass of LiPF to the mixed solution while keeping the temperature outside the reaction vessel below 5°C 6 (Lithium hexafluorophosphate) after stirring continuously until a solution of 1mol / L is evenly prepared, then add 5% (based on the quality of the non-aqueous organic solvent and electrolyte lithium salt as 100%) lithium sulfonyl sulfonyl (structure as follows) and 3 % of 1,3,5-pentanetricarbonitrile and 2% of FEC (fluoroethylene carbonate), and uniformly stirred to obtain the electrolyte solution.

[0080]

[0081] The electrolyte solution prepared in Example 1 of the present invention was tested for performance, see Example 7.

Embodiment 2

[0083] Mix EC (ethylene carbonate): DMC (dimethyl carbonate): EMC (ethyl methyl carbonate) in a ratio of 4:2:4 in a glove box with water content and oxygen content less than 0.1 ppm. Add a certain mass of LiPF to the mixed solution while keeping the temperature outside the reaction vessel below 5°C 6 (Lithium hexafluorophosphate) is continuously stirred to the solution of uniform preparation 1mol / L, then adds 5% (with the quality of non-aqueous organic solvent and electrolyte lithium salt integrated as 100%) of sulfamoyl lithium (structure is the same as embodiment 1) and 3% of glutaronitrile and 2% of DTD (vinyl sulfate), and uniformly stirred to obtain the electrolyte.

[0084] The electrolyte solution prepared in Example 2 of the present invention was tested for performance, see Example 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com