Halide perovskite nano material and preparation method thereof

A halide perovskite, nanomaterial technology, applied in chemical instruments and methods, luminescent materials, nanotechnology, etc., can solve the problem of low stability, poor environmental tolerance, and low generation rate of perovskite quantum dots and other problems, to achieve the effects of low cost, outstanding environmental tolerance, and narrow half-peak width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

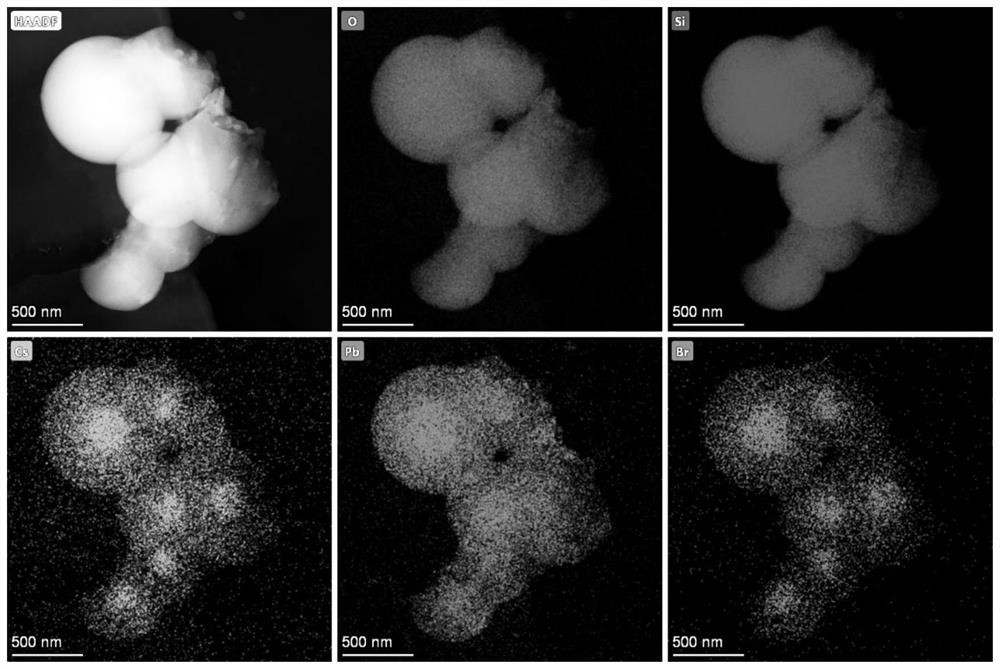

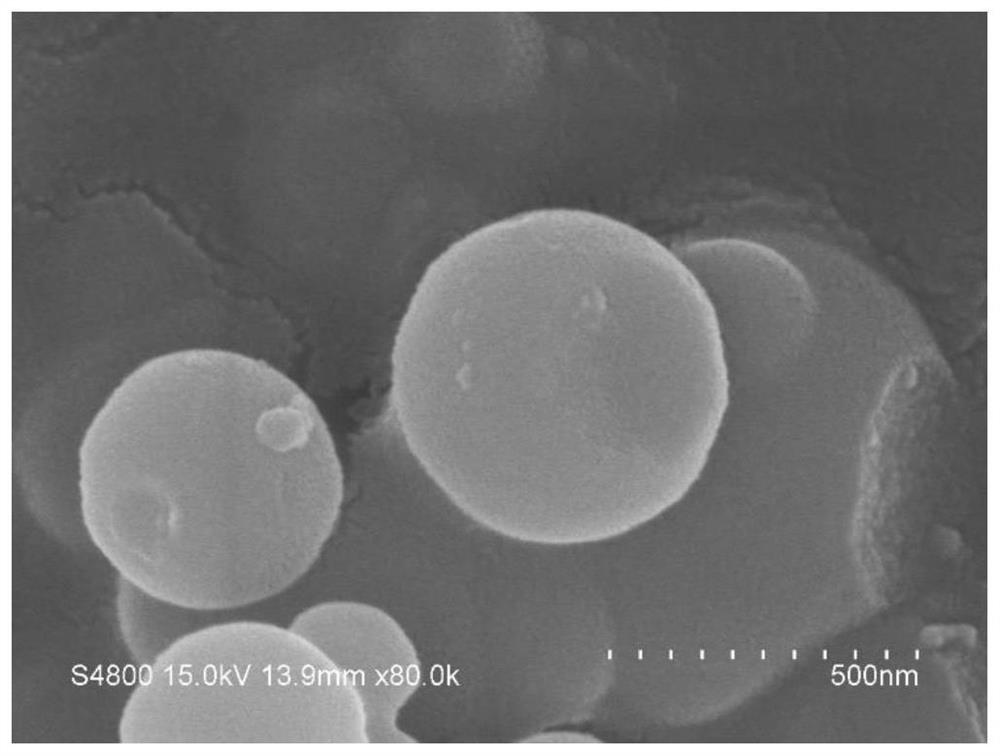

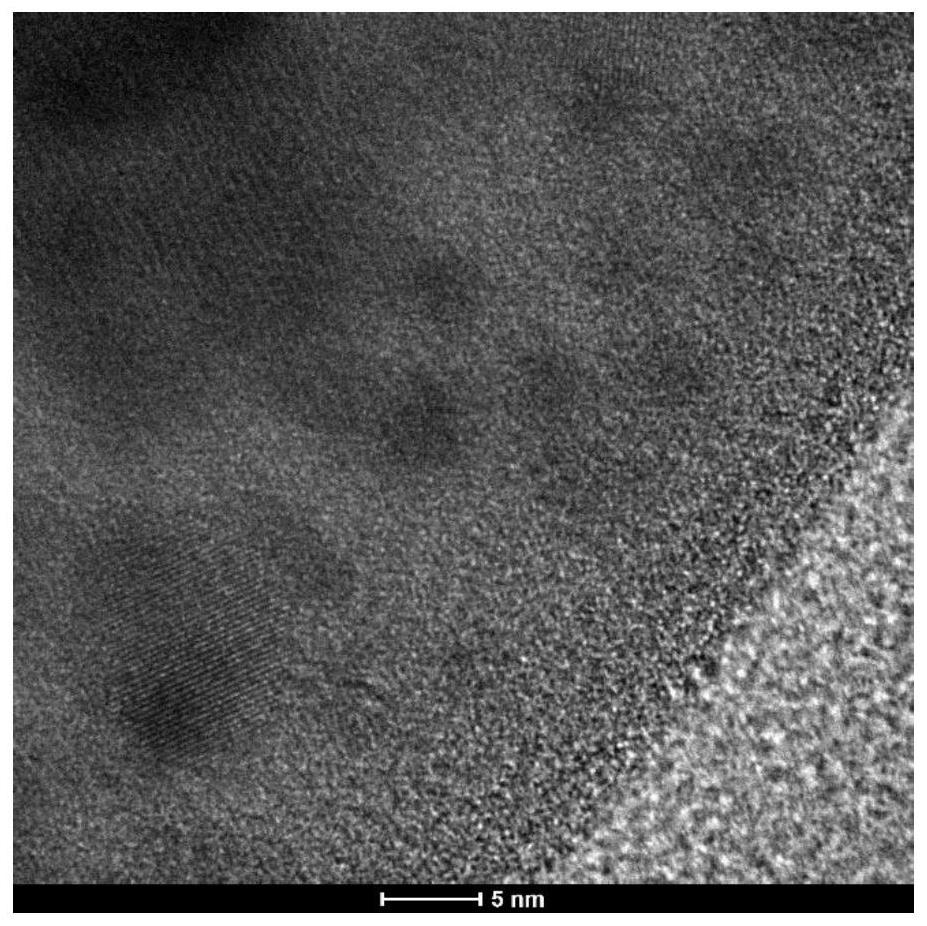

[0069] CsPbBr 3 Preparation of / MS composites

[0070] (1) 0.1mmol lead bromide and 0.1mmol cesium bromide solid powder and 0.8mmol mesoporous silica powder into the grinder, fully ground, solid mixing, to obtain a homogeneous mixture;

[0071] (2) Under an argon atmosphere, the homogeneous mixture obtained in step (1) was heated up at 5 °C / min, melted at 600 °C for 120 min, cooled down at 10 °C / min, and mesoporous silica / perovskite composite materials were formed by cooling crystallization;

[0072] (3) The mesoporous silica / perovskite composite material obtained in step (2) is placed in a muffle furnace, and under an air atmosphere, it is heated at 1 °C / min, insulation at 550 °C for 240 min, and cooled at 10 °C / min;

[0073] (4) The powder obtained in step (3) is placed in saturated sodium sulfate solution, wherein the mass ratio of the powder to saturated sodium sulfate solution is 1:100, stirred at room temperature for 10 hours, centrifuged / washed, precipitated to obtain the...

Embodiment 2

[0075] (1) Put 0.1mmol lead chloride and 0.1mmol cesium chloride solid powder with 1.0mmol mesoporous silica powder into a grinder, grind it thoroughly, mix the solids, and obtain a homogeneous mixture;

[0076] (2) Under an argon atmosphere, the homogeneous mixture obtained in step (1) was heated up at 5 °C / min, melted at 570 °C for 100 min, cooled down at 10 °C / min, and mesoporous silica / perovskite composites were formed by cooling crystallization;

[0077] (3) The mesoporous silica / perovskite composite material obtained in step (2) is placed in a muffle furnace, heated up at 3 °C / min under an air atmosphere, insulation at 550 °C for 200 min, cooled down at 10 °C / min, and oxidized the perovskite nanocrystals exposed to the surface;

[0078](4) The powder obtained in step (3) is placed in saturated sodium sulfate solution, wherein the mass ratio of the powder to saturated sodium sulfate solution is 1:100, the reaction is stirred at room temperature for 8 hours, centrifugation / w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com