Aluminum nitride doped reduced graphene oxide-lithium composite material as well as preparation method and application thereof

A composite material, aluminum nitride technology, which is applied in the field of aluminum nitride-doped reduced graphene oxide-lithium composite materials and its preparation, can solve the problems of reducing battery Coulombic efficiency, low battery energy density, and intensifying dendrite growth. Achieve the effects of alleviating volume change, alleviating growth and negative electrode volume expansion, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing an aluminum nitride-doped reduced graphene oxide-lithium composite material, comprising the following steps:

[0033] mixing the aluminum nitride and graphene oxide aqueous dispersion to obtain a suspension;

[0034] The suspension is suction filtered and dried to obtain an aluminum nitride-doped graphene oxide film;

[0035] The aluminum nitride-doped graphene oxide film is reduced and expanded by thermal radiation to obtain an expanded three-dimensional skeleton of aluminum nitride-doped reduced graphene oxide;

[0036] After pressing the expanded three-dimensional skeleton of the aluminum nitride-doped reduced graphene oxide, the process of absorbing liquid molten metal lithium is carried out to obtain the aluminum nitride-doped reduced graphene oxide-lithium composite material.

[0037] In the present invention, unless otherwise specified, each component is a commercially available product well known to those skilled in...

Embodiment 1

[0063] 2 mg of aluminum nitride with a particle size of 2.5 μm and 10 mL of a graphene oxide aqueous dispersion with a graphene oxide content of 1 mg / mL were ultrasonically mixed for 15 minutes to obtain a suspension;

[0064] After the suspension was vacuum filtered for 3 hours, it was dried at 25°C for 25 hours, and the obtained film was peeled off from the filter membrane to obtain an aluminum nitride-doped graphene oxide film;

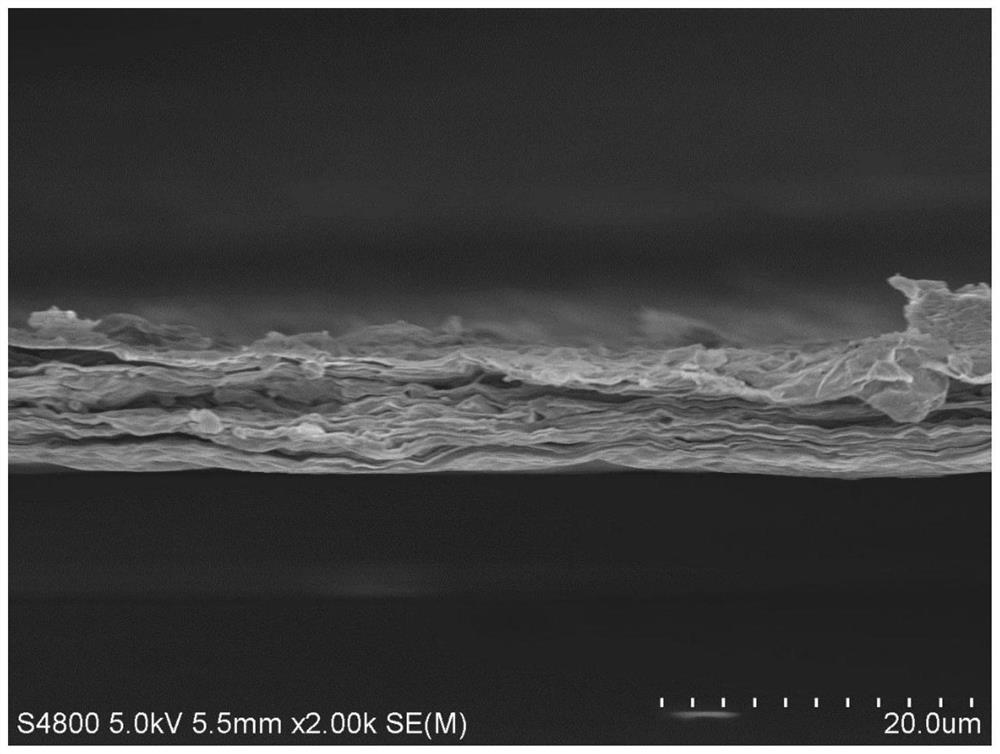

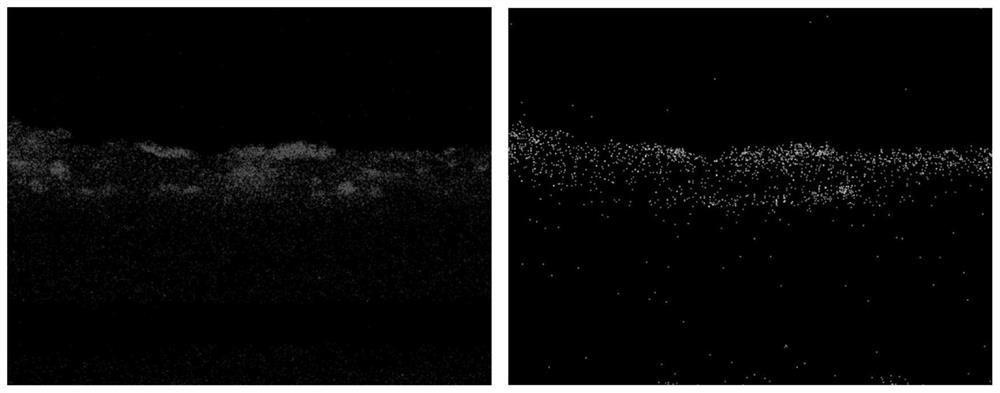

[0065] Using a carbon fiber infrared lamp, the aluminum nitride-doped graphene oxide film is reduced and expanded by thermal radiation at 400W for 4 seconds to obtain an expanded three-dimensional framework of aluminum nitride-doped reduced graphene oxide;

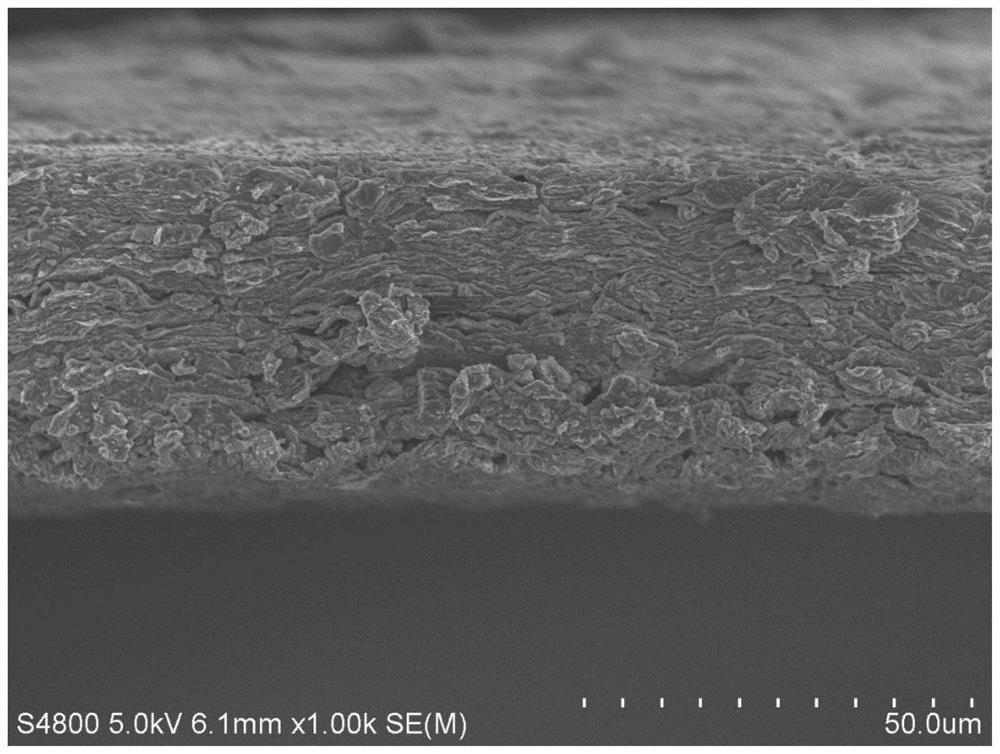

[0066] The aluminum nitride-doped reduced graphene oxide puffed three-dimensional skeleton was rolled three times between rollers with a pitch of 30 μm, and then transferred to a glove box with water and oxygen content <0.1 ppm, and the solid metal The nickel crucible of lithium was kept at 400...

Embodiment 2

[0068] 5 mg of aluminum nitride with a particle size of 2.5 μm and 10 mL of a graphene oxide aqueous dispersion with a graphene oxide content of 1 mg / mL were ultrasonically mixed for 15 minutes to obtain a suspension;

[0069] After the suspension was vacuum filtered for 3 hours, it was dried at 25°C for 25 hours, and the obtained film was peeled off from the filter membrane to obtain an aluminum nitride-doped graphene oxide film;

[0070] Using a carbon fiber infrared lamp, the aluminum nitride-doped graphene oxide film is reduced and expanded by thermal radiation at 400W for 4 seconds to obtain an expanded three-dimensional framework of aluminum nitride-doped reduced graphene oxide;

[0071] The aluminum nitride-doped reduced graphene oxide puffed three-dimensional skeleton was rolled three times between rollers with a spacing of 30 μm, and then transferred to a glove box with water and oxygen content <0.1 ppm, and the solid metal The nickel crucible of lithium was kept at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com