Nanofiber molecular sieve membrane, preparation method and application

A nanofiber and molecular sieve technology, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of isotropic and neutral small molecules or ion sieving, achieve good inhibition effect and improve small molecule selectivity , the effect of retaining water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

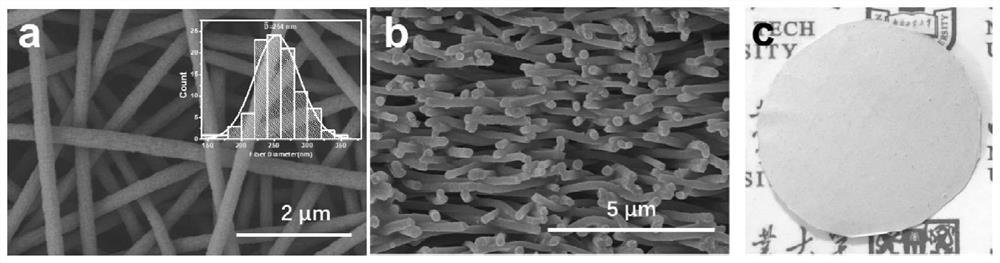

[0041] Example 1 Preparation of PANI / PI electrospinning base film

[0042] The PI and PANI were placed in a vacuum drying oven at 70 °C overnight to remove moisture, and then the spinning solution was prepared. 0.12 wt% LiCl, 14 wt% PI, 8 wt% PANI were dissolved in DMF, respectively, and mechanically stirred at 70 °C for 2 days until the polymer was fully dissolved. Lithium chloride was added to enhance the conductivity of the spinning solution and the solubility of PANI. In addition, in order to prevent the incompletely dissolved PANI nanoparticles from clogging the injection syringe, the spinning solution was centrifuged at 12500 rpm for 30 min, and the fully dissolved casting solution in the upper layer was injected into a dispenser containing 20# (inner diameter of 0.61 mm). needle in the injection syringe. Replace it with a 21# metal needle with an inner diameter of 0.5mm and an outer diameter of 0.8mm, and connect it to the positive pole of the high-voltage DC power su...

Embodiment 2

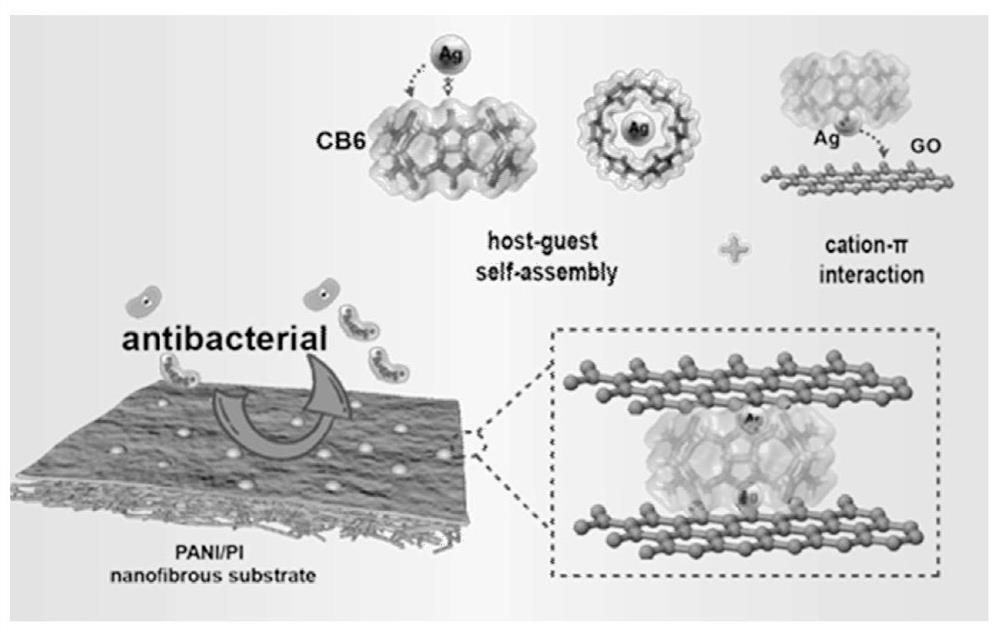

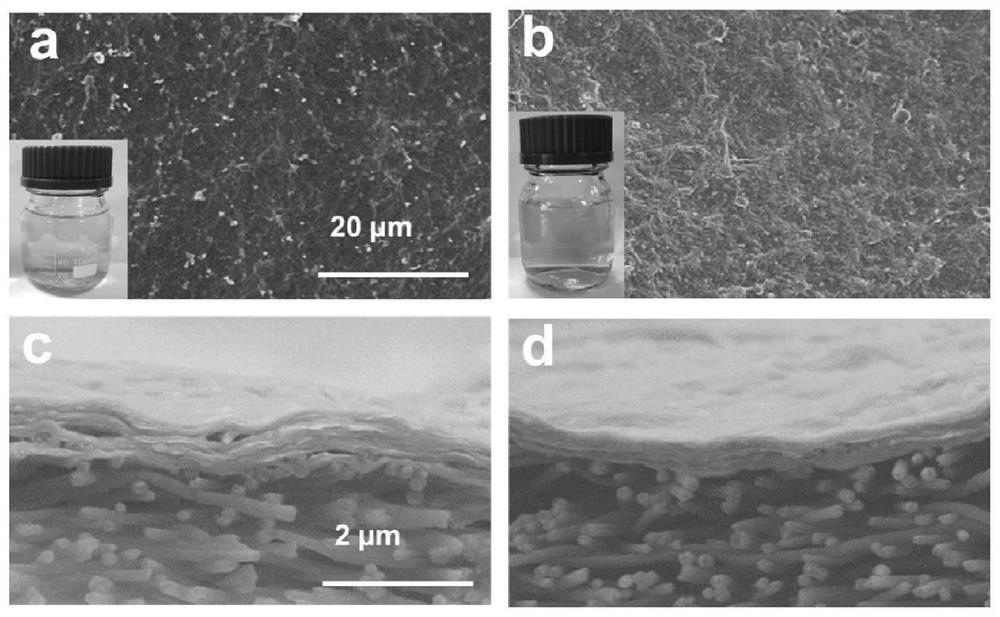

[0046] Example 2 Preparation of Antibacterial Composite Molecular Sieve Membrane

[0047] First, prepare a GO dispersion with a concentration of 0.8 mg / L in a 100 mL silk-neck bottle, and use an ultrasonic cell crusher to sonicate for 2 h. Then Ag ion compound (AgNO 3or AgO) was dissolved in 100 g of deionized water to make the concentration 0.05wt%, and CB6 was added to a concentration of 0.0005wt%. After it was completely dissolved, 4 mL of the above ultrasonic GO dispersion was added, stirred evenly, and then the pressure-assisted filtration method was used. , 150mL of the above mixed solution was deposited on the PANI / PI nanofiber base film under 4bar pressure to form a uniform coating layer (the content of each component is small, but the volume of the coating solution is large, which can make the coating layer more uniform) . The prepared composite molecular sieve membrane was placed in a blast drying oven at 200 °C for heating and reduction for 3 h, and finally the rG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com