Starting-up preheating device for phenol methylation reaction

A technology of phenol methyl and preheating device, which is applied in the direction of feeding device, chemical industry, bulk chemical production, etc., can solve the problems of heat waste of reactants and poor economic benefits, and achieve improved utilization rate, small airflow resistance, The effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

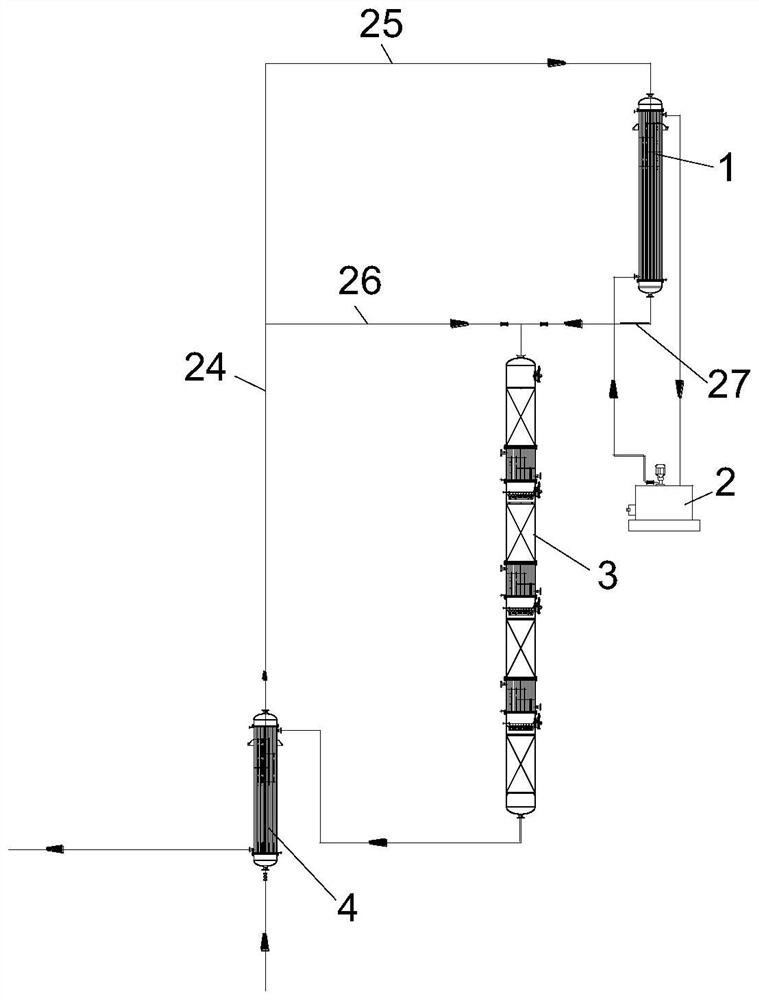

[0034] refer to Figure 1-5, a kind of startup preheating device for phenol methylation reaction, including startup heater 1, molten salt heater 2, reactor 3 and reaction heater 4, and the top reactant outlet of reaction heater 4 is connected with a first The material conduit 24, the end of the first material conduit 24 away from the reaction heater 4 is divided into a first branch conduit 25 and a second branch conduit 26, the first branch conduit 25 away from the first material conduit 24 and the top of the heater 1 The material inlet is connected, and a second material conduit 27 is connected between the bottom end material outlet of the heater 1 and the top material inlet of the reactor 3, and the second branch conduit 26 is away from one end of the first material conduit 24 and the top of the reactor 3. The feed port is connected, the bottom discharge port of the reactor 3 is communicated with the heat exchange channel of the reaction heater 4, the heat medium inlet and o...

Embodiment 2

[0036] refer to Figure 1-5 , the difference between this embodiment and Embodiment 1 is that the molten salt heater 2 includes a molten salt tank 9 and a molten salt pressurizer 22, an electric heater 10 is installed on the molten salt tank 9, and the top of the molten salt tank 9 is fixedly connected with a The molten salt return pipe 11 and the molten salt tank 9 are fixedly connected with a first molten salt discharge pipe 13 at one side close to the molten salt pressurizer 22 and close to the bottom end. The molten salt inlet of the salt pressurizer 22 is communicated, and the second molten salt discharge pipe 6 is installed on the side of the molten salt pressurizer 22 away from the molten salt tank 9, and the molten salt supplementary pipe 12 is also installed on the molten salt tank 9, The molten salt replenishing pipe 12 adds the heat medium into the molten salt tank 9, heats it to a molten state by the electric heater 10, and then introduces the heat medium in the mo...

Embodiment 3

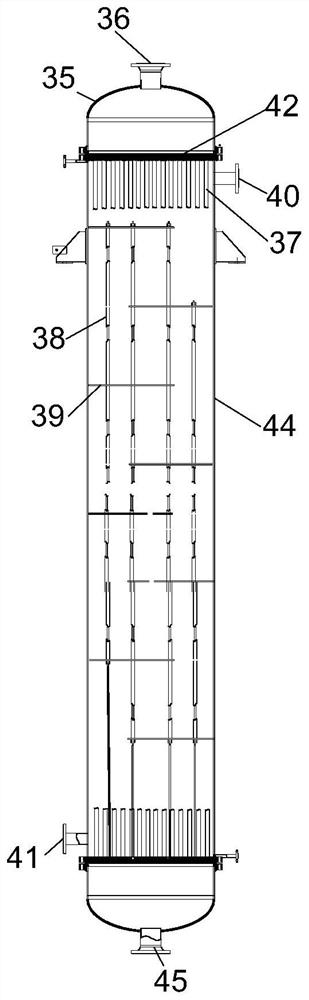

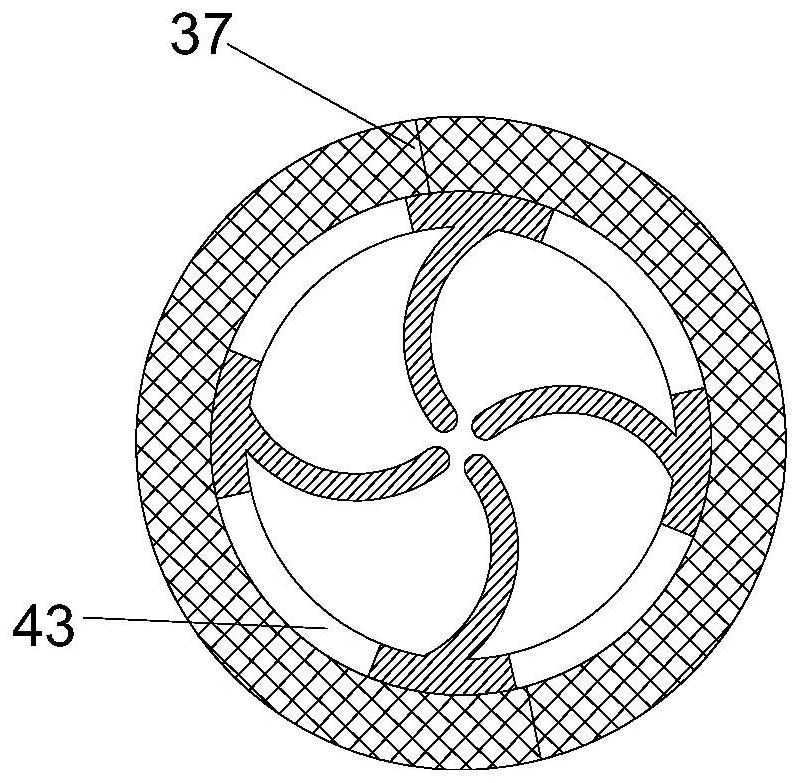

[0038] refer to figure 2 , 3 , 9 and 10, the difference between this embodiment and Embodiment 1 is that the reaction heater 4 is a shell-and-tube heat exchanger, and the reaction heater 4 includes a shell 44, and both ends of the shell 44 are fixedly connected with a head 35, A material inlet pipe 36 and a material discharge pipe 45 are fixedly connected to the two heads 35 respectively, and a tube plate 42 is fixedly connected to the shell 44 near the top and bottom ends, and a heat exchange is fixedly connected between the two tube plates 42. The tube bundle 37, the two ends of the heat exchange tube bundle 37 are respectively connected with the inside of the two heads 35, and the two sides of the casing 44 are fixedly connected with a heat medium inlet pipe 40 and a heat medium discharge pipe 41 at the position near the top end and the position near the bottom end, respectively. Random packing 43 is added to the heat exchange tube bundle 37, the gaseous high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com