Composite iron-carbon filler based on sludge iron-rich biochar as well as preparation and application of composite iron-carbon filler

A technology of iron-carbon filler and biochar is applied in the field of pollutant degradation, which can solve the problem of low reactivity of iron-carbon filler, and achieve the effects of improving wastewater treatment efficiency, uniform iron phase loading and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

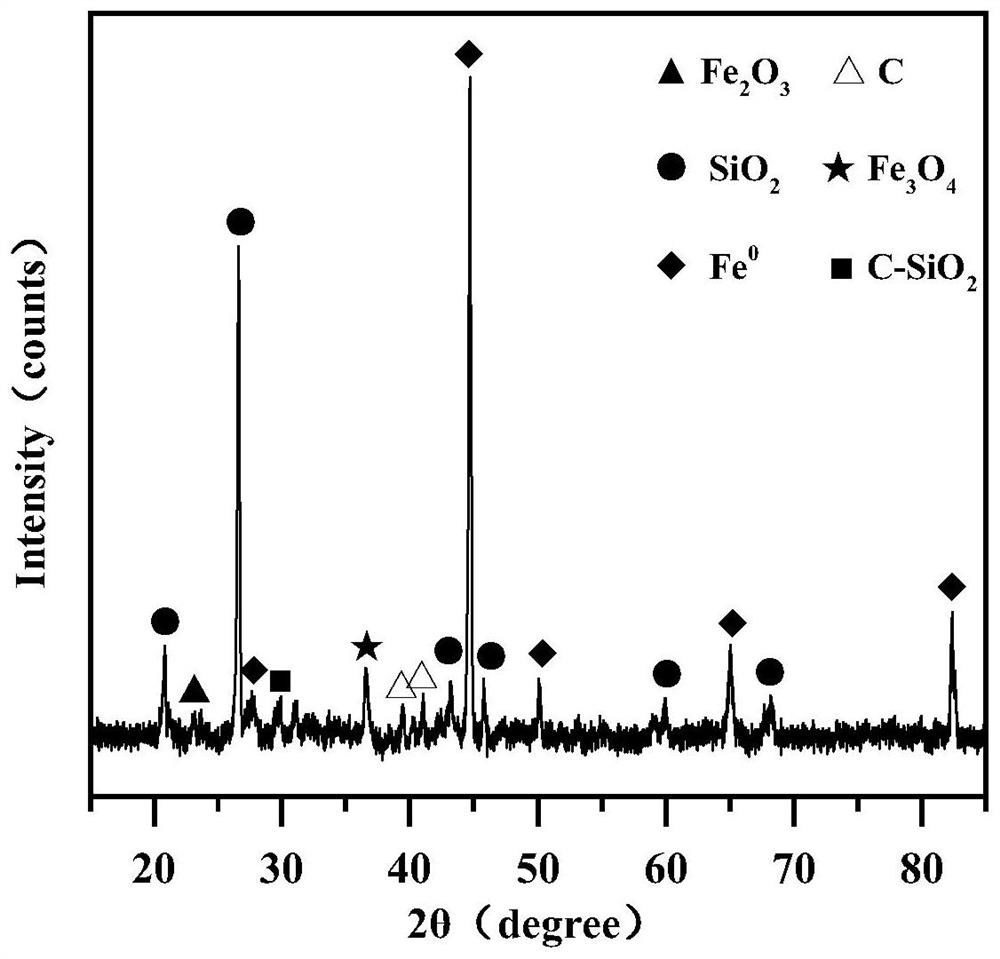

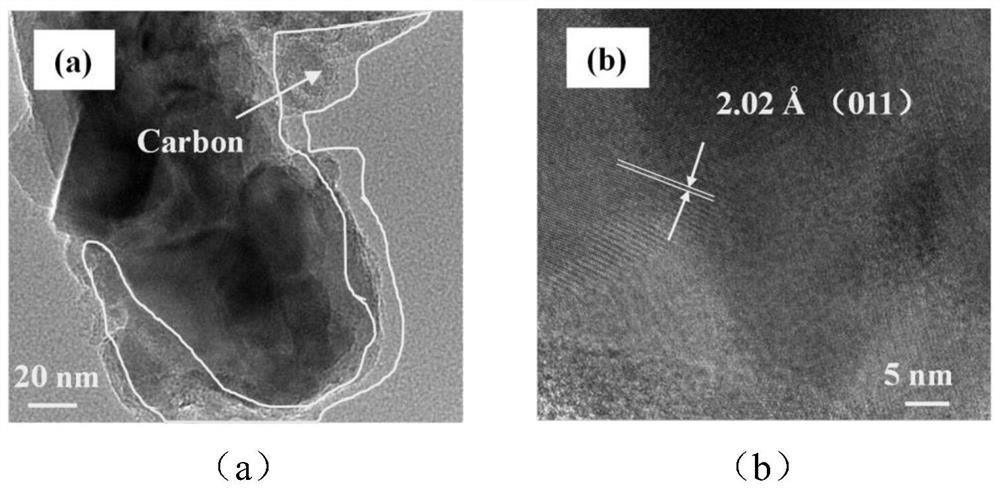

[0040] The preparation process is to directly use iron-containing sludge for pyrolysis to obtain sludge iron-rich biochar, so that the reactive iron phase is evenly distributed on the sludge biochar skeleton.

[0041] In order to achieve the above objectives, dehydration of iron-containing sludge, dry grinding of iron-containing dewatered cake, iron-carbon ratio adjustment of iron-containing dried sludge before pyrolysis, pyrolysis process parameters (including temperature, time, protective gas flow rate) ), the proportion deployment of sludge iron-rich biochar and binder, the preparation conditions and preparation methods of composite iron-carbon filler were optimized and controlled.

[0042] The auxiliary components can be but not limited to sodium silicate, sodium humate, sodium carboxymethyl cellulose, hydroxypropyl cellulose, calcium chloride, clay, polyurethane, epoxy resin and acrylates have similar Forming and bonding agent.

[0043] The iron salt conditioning agent d...

Embodiment 1

[0081] The composite iron-carbon filler is composed of the following components: 70 parts by weight of sludge iron-rich biochar, 10 parts by weight of sodium silicate, and 20 parts by weight of sodium humate;

[0082] The method for preparing the above-mentioned composite iron-carbon filler comprises the following steps:

[0083] Step 1: Dissolve the binder sodium silicate in a small amount of water;

[0084] Step 2: Mix the sludge iron-rich biochar, sodium silicate, and sodium humate evenly according to the weight ratio, add pure water during the process, and hand-knead into spherical composite iron-carbon filler particles;

[0085] Step 3: Dry the pellets obtained in Step 2 at 60°C for 3 hours;

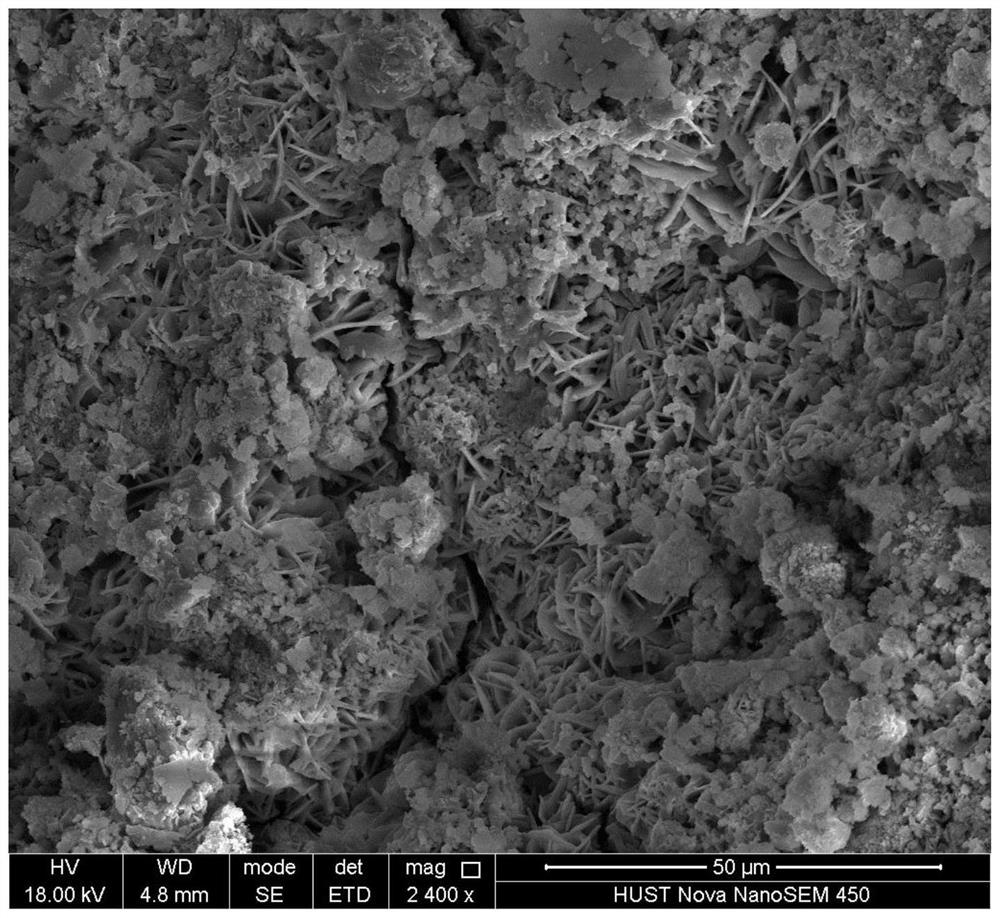

[0086] Step 4: Calcining the pellets formed in Step 3 at 700° C. for 1 hour in the same atmosphere of a tube furnace to obtain a sintered composite iron-carbon filler with abundant pores.

Embodiment 2

[0088] The composite iron-carbon filler is composed of the following components: 70 parts by weight of sludge iron-rich biochar, 10 parts by weight of sodium silicate, and 20 parts by weight of sodium humate;

[0089] The method for preparing the above-mentioned composite iron-carbon filler comprises the following steps:

[0090] Step 1: Dissolve the binder sodium silicate in a small amount of water;

[0091] Step 2: Mix the sludge iron-rich biochar, sodium silicate, and sodium humate evenly according to the weight ratio, add pure water during the process, and hand-knead into spherical composite iron-carbon filler particles;

[0092] Step 3: Dry the pellets obtained in Step 2 at 60°C for 3 hours;

[0093] Step 4: Calcining the pellets formed in Step 3 at 800° C. for 1 hour in the same atmosphere of a tube furnace to obtain a sintered composite iron-carbon filler with abundant pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com