Preparation method and application of microbial immobilized composite particles

A technology of microbial immobilization and composite particles, which is applied in the field of environmental bioremediation, can solve the problems of polyvinyl alcohol adhesion and poor mass transfer performance, and achieve the effects of improving removal effect, promoting adsorption and decomposition, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

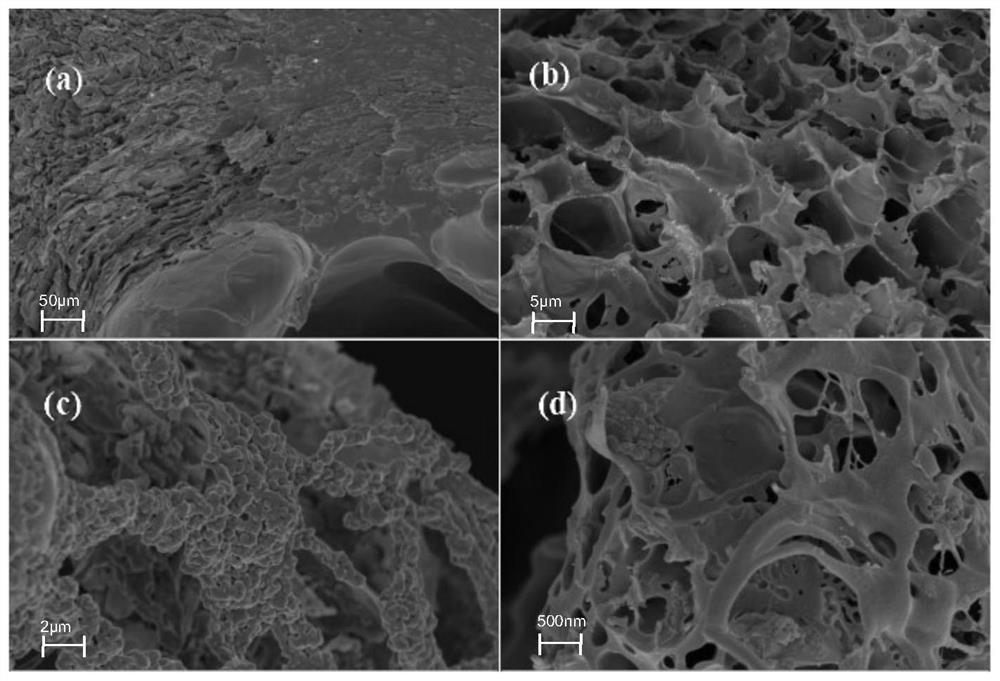

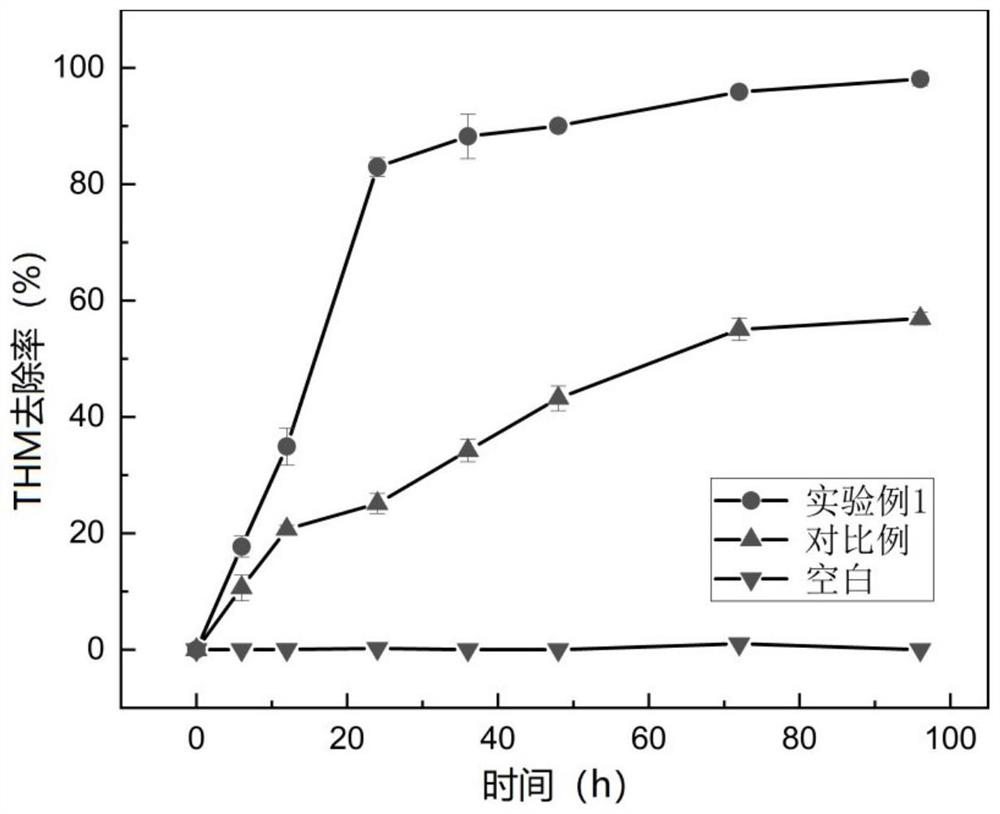

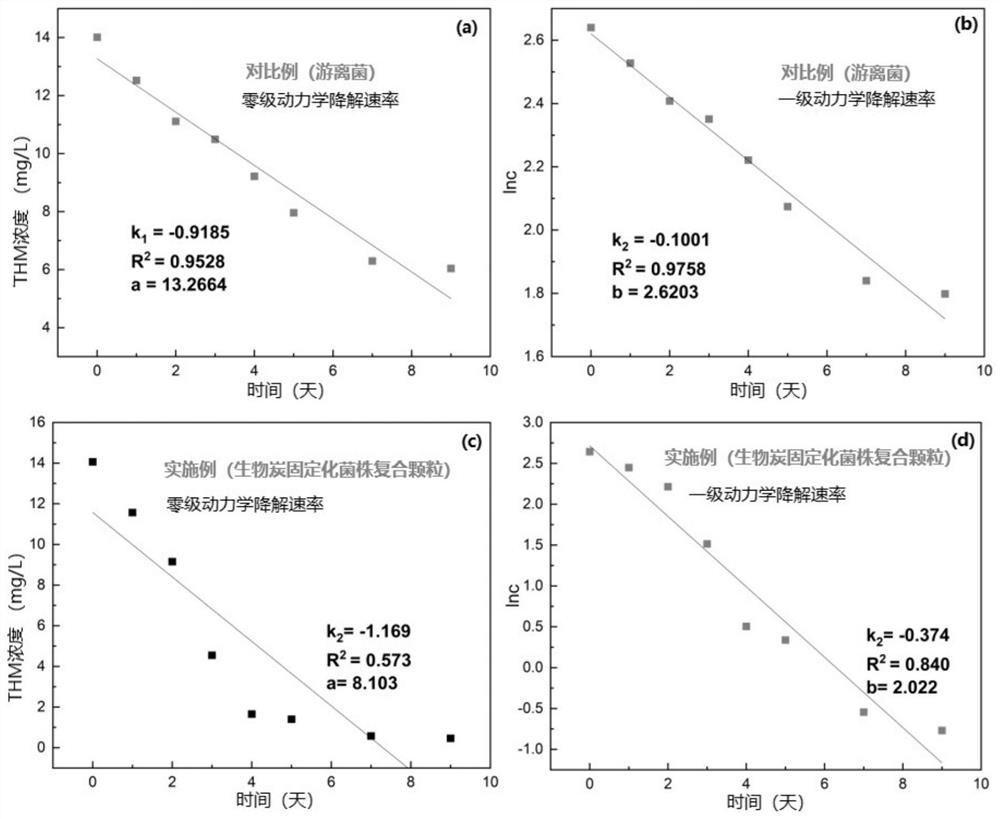

[0053] A preparation method of microbial immobilized composite particles:

[0054] S1. After washing and drying the rice husks with deionized water, put them in a crucible and place them in a tube furnace. Under an argon atmosphere, react at 700° C. for 3 hours. After cooling to room temperature, take out the rice husks, and then use 0.1 mol of ·L -1 HCl and HNO 3 The mixed solution is washed until the lotion is neutral, the rice husks are dried, and then ground through a 100-mesh sieve to obtain biochar;

[0055] S2. Inoculate the Bacillus aureus strain in 100mL LB liquid medium, put it into a shaker for constant temperature cultivation (30°C, 160rpm), cultivate to the late logarithmic growth phase, and centrifuge the medium at room temperature (×4000g, 10min), Then washed with sterile water, resuspended in 0.9% physiological saline to obtain a bacterial suspension with an OD600 value of 0.75, and then added 0.6 g of the biochar to 50 mL of the bacterial suspension, and all...

Embodiment 2

[0061] A preparation method of microbial immobilized composite particles:

[0062] S1. After washing and drying the moso bamboo with deionized water, put it in a crucible and place it in a tube furnace. Under an argon atmosphere, react at 850° C. for 2 hours. After cooling to room temperature, take out the rice husk, and then use 0.1 mol· L -1 HCl and HNO 3 The mixed solution is washed until the lotion is neutral, the rice husks are dried, and then ground through a 100-mesh sieve to obtain biochar;

[0063] S2. Inoculate the Bacillus aureus strain in 100mL LB liquid medium, put it into a shaker for constant temperature cultivation (30°C, 160rpm), cultivate to the late logarithmic growth phase, and centrifuge the medium at room temperature (×4000g, 10min), Then washed with sterile water, resuspended in 0.9% physiological saline to obtain a bacterial suspension with an OD600 value of 0.85, then added 0.8 g of the biochar to 50 mL of the bacterial suspension, and let stand for ...

Embodiment 3

[0068] A preparation method of microbial immobilized composite particles:

[0069] S1. After washing and drying the rice bran with deionized water, put it in a crucible and place it in a tube furnace. Under an argon atmosphere, react at 650° C. for 4 h. After cooling to room temperature, take out the rice husk, and then use 0.1 mol· L -1 HCl and HNO 3 The mixed solution is washed until the lotion is neutral, the rice husks are dried, and then ground through a 100-mesh sieve to obtain biochar;

[0070] S2. Inoculate the Bacillus aureus strain in 100mL LB liquid medium, put it into a shaker for constant temperature cultivation (30°C, 160rpm), cultivate to the late logarithmic growth phase, and centrifuge the medium at room temperature (×4000g, 10min), Then washed with sterile water, resuspended in 0.9% physiological saline to obtain a bacterial suspension with an OD600 value of 1.0, then 1.0 g of the biochar was added to 50 mL of the bacterial suspension, and allowed to stand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com