Low-temperature electrolyte and lithium ion battery containing same

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as hindering the low-temperature performance of the battery, increasing the internal resistance of the battery, etc., achieving excellent low-temperature performance and cycle performance, and improving conductivity. efficiency, high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

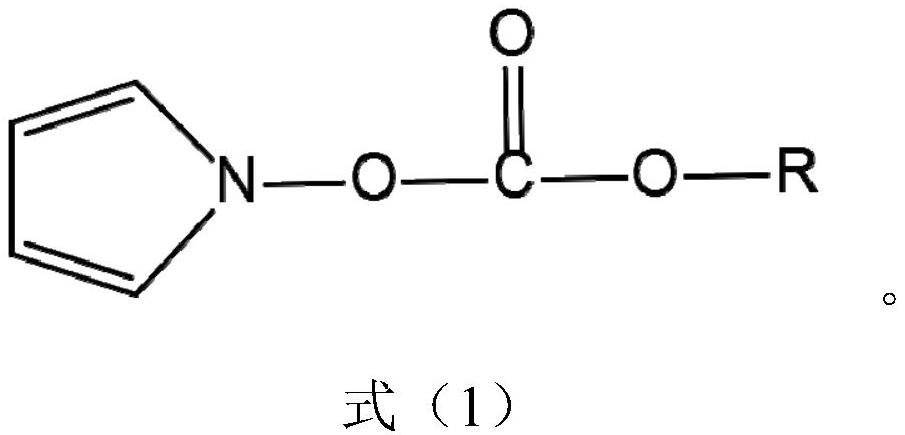

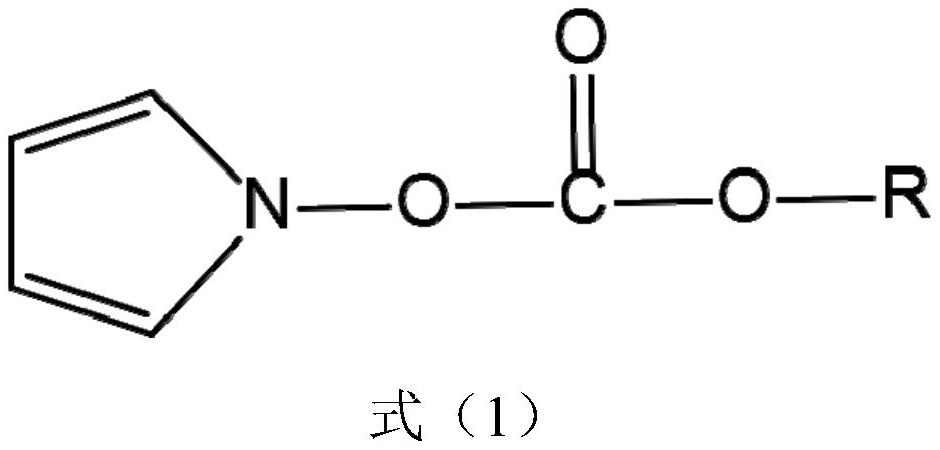

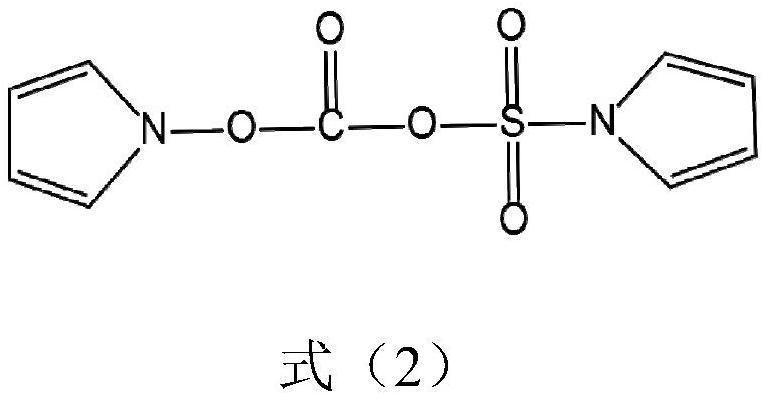

[0034] In an inert atmosphere glove box with both water content and oxygen content below 5 ppm, the organic solvent ethylene carbonate (EC) and ethyl methyl carbonate (EMC) were prepared into an organic solvent in a mass ratio of 1:1. Slowly add lithium hexafluorophosphate to the solvent to dissolve, then add 1% fluoroethylene carbonate and 1% pyrrole-1-sulfonic acid pyrrol-1-yloxyalkanecarboxylic acid anhydride (structural formula shown in formula (2)) ), stirring to make it completely dissolved to obtain a lithium-ion battery electrolyte. The mass fractions of lithium hexafluorophosphate, organic solvent, fluoroethylene carbonate, and pyrrole-1-sulfonic acid pyrrol-1-yloxanecarboxylic acid anhydride (denoted as a) were 13.5%, 84.5%, 1%, and 1%, respectively.

[0035]

[0036] The preparation method of the (pyrrol-1-yloxy) methane acid methyl ester compound is the existing method, and the (pyrrol-1-yloxy) methane acid methyl ester compound in the prior art can also be used...

Embodiment 2

[0041] The organic solvents ethylene carbonate (EC), ethyl methyl carbonate (EMC), and dimethyl carbonate (DMC) were mixed in a mass of 1:1:1 in an inert atmosphere glove box with both water and oxygen content below 5 ppm. Than be prepared into an organic solvent, slowly add lithium hexafluorophosphate to the prepared organic solvent to dissolve, then add 1% of the total mass of the electrolyte, fluoroethylene carbonate, 1% of (pyrrol-1-yloxy) formic acid-pyrrole-2 -base ester (the structural formula is shown in formula (3)), which is completely dissolved after stirring to obtain an electrolyte for a lithium ion battery. The mass fractions of lithium hexafluorophosphate, organic solvent, fluoroethylene carbonate, and (pyrrol-1-yloxy)carboxylate-pyrrol-2-yl ester (denoted as b) were 13.5%, 84.5%, 1%, and 1%, respectively.

[0042]

[0043] Compared with Example 1, R in the preparation process of (pyrrol-1-yloxy) formic acid-pyrrol-2-yl ester in this example is

[0044] Su...

Embodiment 3

[0046] The organic solvents ethylene carbonate (EC), ethyl methyl carbonate (EMC) and dimethyl carbonate were prepared in a mass ratio of 1:1:1 in an inert atmosphere glove box with water content and oxygen content below 5ppm. organic solvent, slowly add lithium hexafluorophosphate (LiPF 6 ) to dissolve, then add 1% fluoroethylene carbonate and 1% (pyrrol-1-yloxy) trifluoromethyl formate (structural formula is shown in formula (4)) of the total mass of the electrolyte, and after stirring It was completely dissolved to obtain a lithium-ion battery electrolyte. The mass fractions of lithium hexafluorophosphate, organic solvent, fluoroethylene carbonate and trifluoromethyl (pyrrol-1-yloxy)formate (denoted as c) were 13.5%, 84.5%, 1% and 1%, respectively.

[0047]

[0048] Compared with Example 1, in this example (pyrrol-1-yloxy) trifluoromethyl formate preparation process R is -CF 3 .

[0049] Subsequent battery preparation operations were the same as in Comparative Example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com