Ceramic combined hercynite kilneye castable and preparation method thereof

An iron-aluminum spinel and ceramic combination technology, applied in the field of refractory materials, can solve the problems of prone to volume expansion and short service life, and achieve the effects of reducing internal stress, reducing cracking and peeling, and maintaining a stable overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

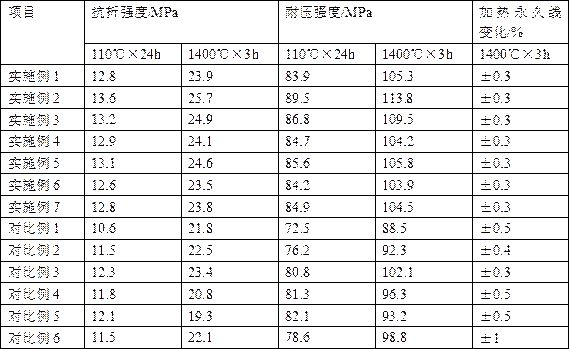

Examples

preparation example Construction

[0039] The preparation method of porous silicon aluminum ceramic among the present invention is as follows:

[0040] Preparation of Porous Si-Al Ceramics (A1):

[0041] (1) Dissolve 80g of tetraethoxysilane and 1g of boric acid in 100g of water, add 5ml of glacial acetic acid, and hydrolyze at 30°C for 3 hours to obtain silica sol;

[0042] (2) Add 70g of alumina micropowder and 15g of starch to the above silica sol, and mix well to obtain a pasty mixture;

[0043] (3) Mold the pasty mixture into spherical particles with a diameter of 3-5 mm, and air-dry to obtain blanks;

[0044] (4) The blank was first sintered at 800°C for 5 hours, and then under the protection of nitrogen, the temperature was raised to 1450°C and kept for 4 hours to complete ceramicization, and porous silicon-aluminum ceramics (A1) were obtained.

[0045] Preparation of Porous Si-Al Ceramics (A2):

[0046] (1) Dissolve 80g of tetraethoxysilane and 1g of boric acid in 100g of water, add 5ml of glacial ac...

Embodiment 1

[0071] A pottery-bonded iron-aluminum spinel kiln mouth castable, said castable in parts by weight, comprising: 45 parts of iron-aluminum spinel, 20 parts of porous silicon-aluminum ceramics (A1), 18 parts of alumina micropowder, 10 parts of silicon carbide powder, 6 parts of metal silicon powder, 2.5 parts of flake graphite powder, 0.5 parts of boric anhydride and 3 parts of silica sol.

[0072] The silica sol is obtained by dissolving 50 g of tetraethoxysilane in 100 g of water and hydrolyzing it at 30° C. for 3 hours, the same below.

[0073] The preparation process of the castable is as follows, dissolving boric anhydride and silica sol in 5 parts of water to form a binder solution, and then spraying the binder solution evenly on the surface of the porous silicon-aluminum ceramic, adding powder, mixing evenly, and then adding iron The alumina spinel is continuously mixed evenly to obtain the kiln mouth castable, the same below.

Embodiment 2

[0075] A pottery-bonded iron-aluminum spinel kiln mouth castable, said castable in parts by weight, comprising: 45 parts of iron-aluminum spinel, 25 parts of porous silicon-aluminum ceramics (A1), 18 parts of alumina micropowder, 10 parts of silicon carbide powder, 6 parts of metal silicon powder, 2.5 parts of flake graphite powder, 0.5 parts of boric anhydride and 3 parts of silica sol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com