High-content element uniformly-doped lithium cobalt oxide precursor and preparation method thereof

A technology of content elements and precursors, which is applied in the field of lithium cobaltate precursors uniformly doped with high content elements and its preparation, can solve the problems of uniform doping of aluminum elements, uncharacterized availability, and complicated operations, and achieve reduction The risk of secondary nucleation, the effect of increasing the reaction rate and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In the preparation process of the lithium cobalt oxide precursor material, when it meets one or more of the following conditions, the prepared lithium cobalt oxide precursor can have better quality:

[0046] The concentration of cobalt solution is 100g / L-150g / L;

[0047] Metal salt solution, wherein the metal is one or more of Mg, Al, Zr, La, Y, Ni, Mn, Cr, V, Ti;

[0048] The metal concentration of the doped metal salt is 10g / L-40g / L;

[0049] The alkaline solution is an aqueous solution of ammonium bicarbonate or sodium carbonate;

[0050] The concentration of alkali solution is 130-240g / L;

[0051] In step 2, the pH value of the first bottom liquid is 7.5 to 8.5;

[0052] In step 2, the alkalinity of the first bottom liquid is 0.25~0.35mol / L;

[0053] The precipitation temperature in step 2 is 30~40 ℃;

[0054] In step 2, the stirring speed is 190~230rpm;

[0055] In step 2, the pH value of the precipitation is 7.0-8.0.

[0056] The seed grain size of the coba...

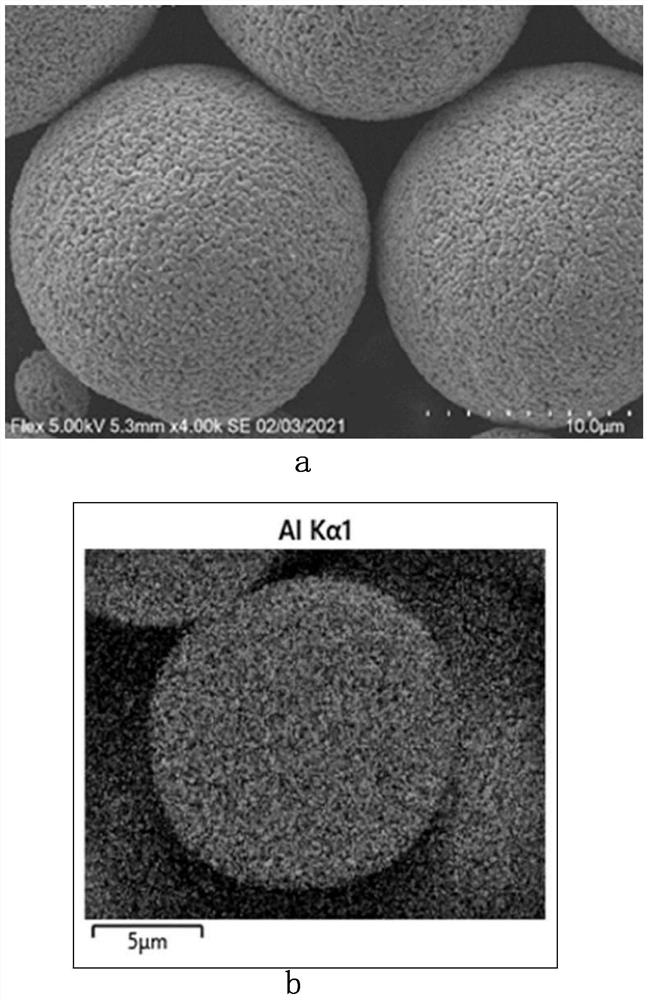

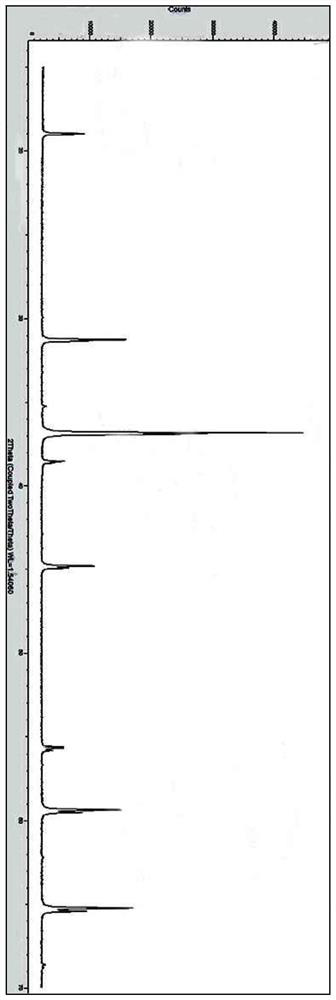

Embodiment 1

[0072] Step 1: Preparation of raw materials. Prepare a cobalt chloride solution with a metal concentration of 100 g / L, an ammonium bicarbonate solution with a metal concentration of 130 g / L, and an aluminum sulfate solution with a metal concentration of 10 g / L, for subsequent use.

[0073] Step 2: Preparation of cobalt carbonate seed crystals. Deionized water and ammonium bicarbonate solution were added to the reaction kettle, and the temperature was raised to 30° C. of the reaction kettle to obtain a first bottom liquid with a pH value of 7.55 and an alkalinity of 0.252 mol / L. The stirring speed is 190rpm, then the metering pump of cobalt chloride, ammonium bicarbonate and aluminum sulfate feed liquid is turned on to start feeding, the flow rate of cobalt chloride is 50L / h, the flow rate of aluminum sulfate is 5L / h, and the flow rate of ammonium bicarbonate is adjusted to control The pH value of the reactor was 7.0. The precipitation process uses positive pressure micropore...

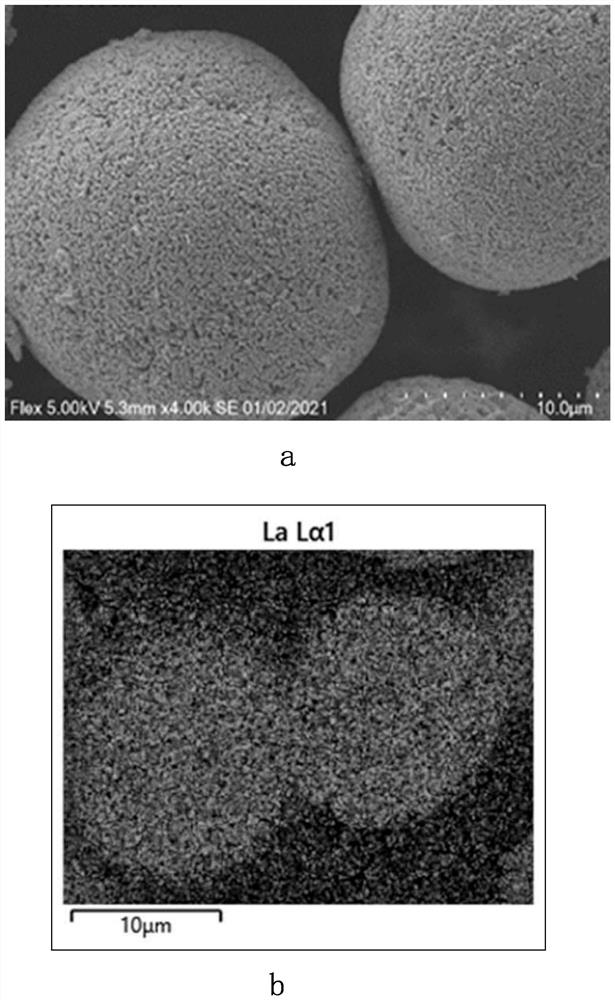

Embodiment 2

[0078] Step 1: Preparation of raw materials. A cobalt chloride solution with a metal concentration of 150 g / L, a sodium carbonate solution with a metal concentration of 240 g / L, and a lanthanum chloride solution with a metal concentration of 40 g / L were prepared for subsequent use.

[0079] Step 2: Preparation of cobalt carbonate seed crystals. Add deionized water and sodium carbonate solution to the reaction kettle, be warming up to 40 ℃ of reaction kettle temperature, obtain the bottom liquid whose pH value is 8.44, and alkalinity is 0.347mol / L. The stirring speed is 230rpm, then the metering pump of cobalt chloride, sodium carbonate and lanthanum chloride feed liquid is turned on to start feeding, the flow rate of cobalt chloride is 50L / h, the flow rate of lanthanum chloride is 1.87 / h, and the flow rate of sodium carbonate is adjusted to control The pH value of the reactor was 8.0. The precipitation process uses positive pressure micropores to concentrate the slurry. Whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com