High-thermal-conductivity anticorrosive paint for heat exchanger tube bundle as well as preparation and use methods of high-thermal-conductivity anticorrosive paint

A technology of anti-corrosion coatings and high thermal conductivity, which is applied in the direction of anti-corrosion coatings, fireproof coatings, coatings, etc., to achieve the effect of coating realization, easy implementation, and full coverage coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

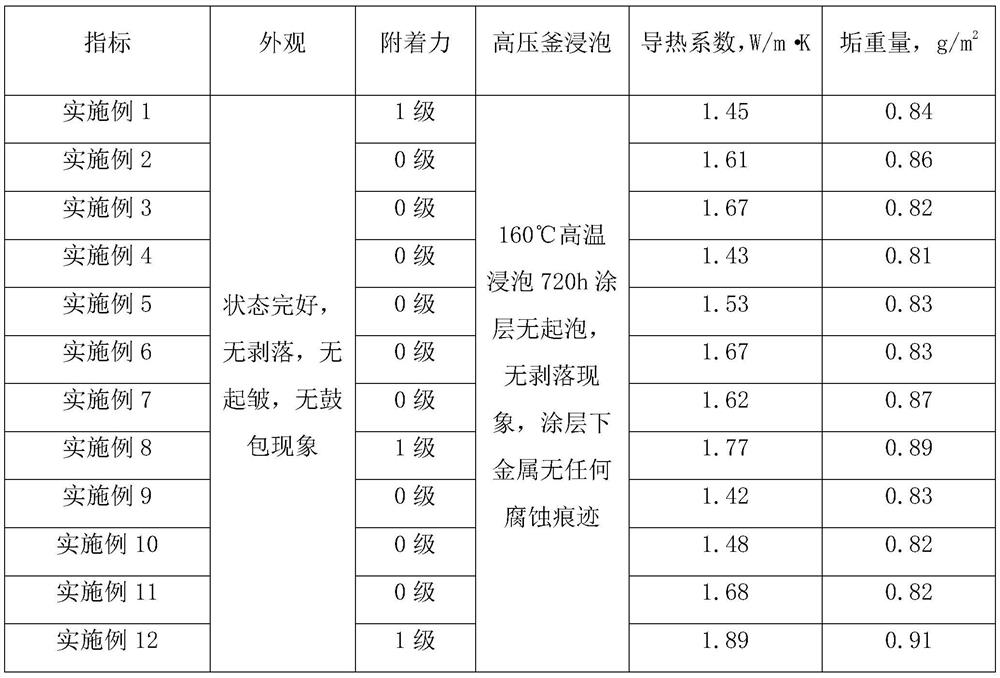

Examples

preparation example Construction

[0055] The invention also provides a preparation method of a high thermal conductivity anti-corrosion coating for heat exchanger tube bundles, comprising the following steps:

[0056] Prepare the components in the stated portions;

[0057] Mixing the nano-aluminum nitride powder and the xylene to obtain an aluminum nitride solution;

[0058] Mix the methylphenylsiloxane resin, the silane coupling agent, and the leveling agent with the model BYK3230 with the aluminum nitride solution, stir evenly, and then age at room temperature to prepare the High thermal conductivity anti-corrosion coating for heat exchanger tube bundles.

[0059] After mixing the nano aluminum nitride powder and the xylene, ultrasonically disperse for 30-60min. And, it needs to be aged at room temperature for 20min.

[0060] The preparation method has the following technical effects:

[0061] The preparation method is simple to operate, easy to implement, and has good controllability, which is favorable...

Embodiment 1

[0071] Mix 10 parts of nano aluminum nitride powder and 15 parts of xylene, and ultrasonically disperse for 30min to obtain an aluminum nitride solution;

[0072] Mix 1 part of KH550 silane coupling agent, 0.2 part of BYK3230 anti-foaming leveling agent and aluminum nitride solution, and stir evenly at high speed;

[0073] Add 40 parts of methylphenylsiloxane resin, stir evenly at high speed, and then age at room temperature for 20 minutes to obtain the high thermal conductivity and high temperature resistant anti-corrosion coating;

[0074] The coating is applied twice, and after each coating is completed, it is placed in an environment of 120°C for high-temperature curing. During the curing process, the temperature is controlled to ensure that there will be no sudden cooling and sudden heating.

Embodiment 2

[0076] Mix 20 parts of nano aluminum nitride powder and 20 parts of xylene, and ultrasonically disperse for 30 minutes to obtain an aluminum nitride solution;

[0077] Mix 1.5 parts of KH550 silane coupling agent, 0.5 part of BYK3230 antifoaming and leveling agent with aluminum nitride solution, and stir evenly at high speed;

[0078] Add 50 parts of methylphenylsiloxane resin, stir evenly at high speed, and then age at room temperature for 20 minutes to obtain the high thermal conductivity and high temperature resistant anti-corrosion coating;

[0079] The coating is applied twice, and after each coating is completed, it is placed in an environment of 150 °C for high temperature curing. During the curing process, the temperature is controlled to ensure that it will not experience sudden cooling and sudden heating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com