Antimony oxide powder pure oxygen side-blowing reduction smelting method

A technology of antimony oxide powder and pure oxygen, applied in furnaces, lighting and heating equipment, crucible furnaces, etc., can solve the problems of high energy consumption, high labor intensity, and high production cost of antimony oxide powder, and achieve reduced labor intensity and process control Accurate, exhaust emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

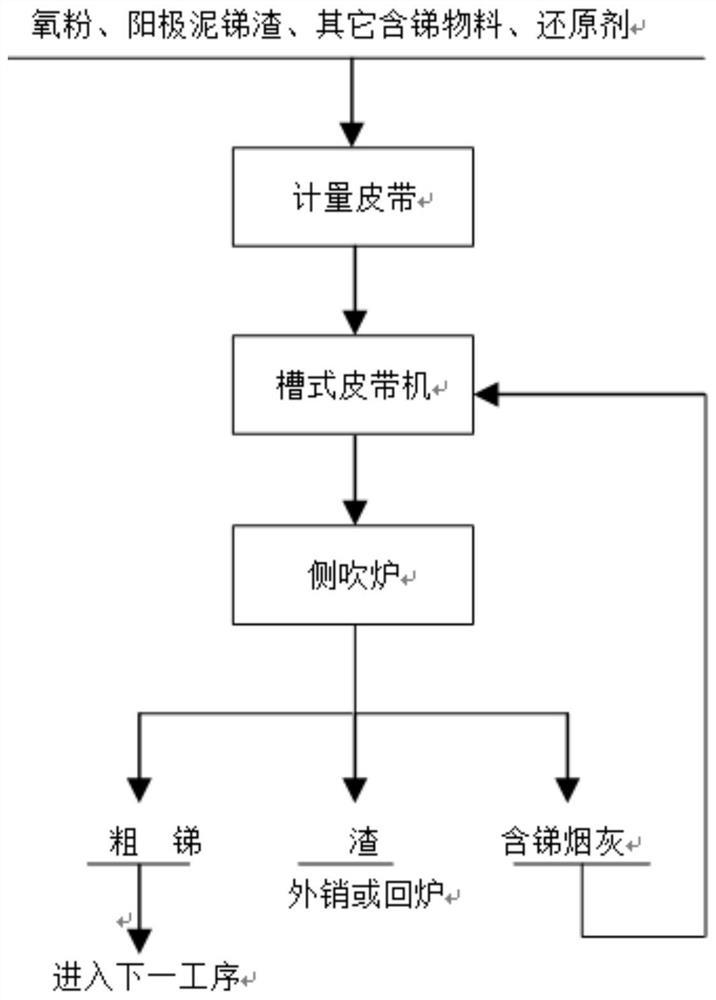

[0024] A pure oxygen side-blown reduction smelting method for antimony oxide powder, comprising the following steps:

[0025] 1) According to the weight ratio of antimony-containing material: reducing agent = 10:1, mix evenly, the feeding system adopts the grab bucket for batching, and after the metering belt is measured, the material is directly sent into the side-blown furnace by the belt, and passes through the bottom of the furnace. The side of the furnace and the top of the furnace continuously provide heat to the furnace with pure oxygen combustion reducing agent, the pressure is controlled at 10-15kPa, and the flow rate is 80-90m 3 / h, control the temperature in the furnace at 1150-1450℃, and the raw and auxiliary materials are fully melted and reduced;

[0026] The antimony-containing materials include antimony oxide powder, anode slime antimony slag or other antimony-containing raw materials, in any proportion when mixed; the reducing agent is anthracite; the side-blo...

Embodiment 2

[0029] A kind of antimony oxide powder pure oxygen side-blown reduction smelting method, compared with embodiment 1, step 1) according to the weight ratio of antimony-containing material: reducing agent=9.5:1, other is the same as embodiment 1.

Embodiment 3

[0031] A kind of antimony oxide powder pure oxygen side-blown reduction smelting method, compared with embodiment 1, step 1) according to the weight ratio of antimony-containing material: reducing agent=10.5:1, other is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com