Copper indium tin selenide/zinc selenide core-shell quantum dot and preparation method and application thereof

A core-shell quantum dot, copper indium tin technology, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of poor working durability, high dark current, and high heavy metals, and solve the problem of high cost , the effect of improving the generation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

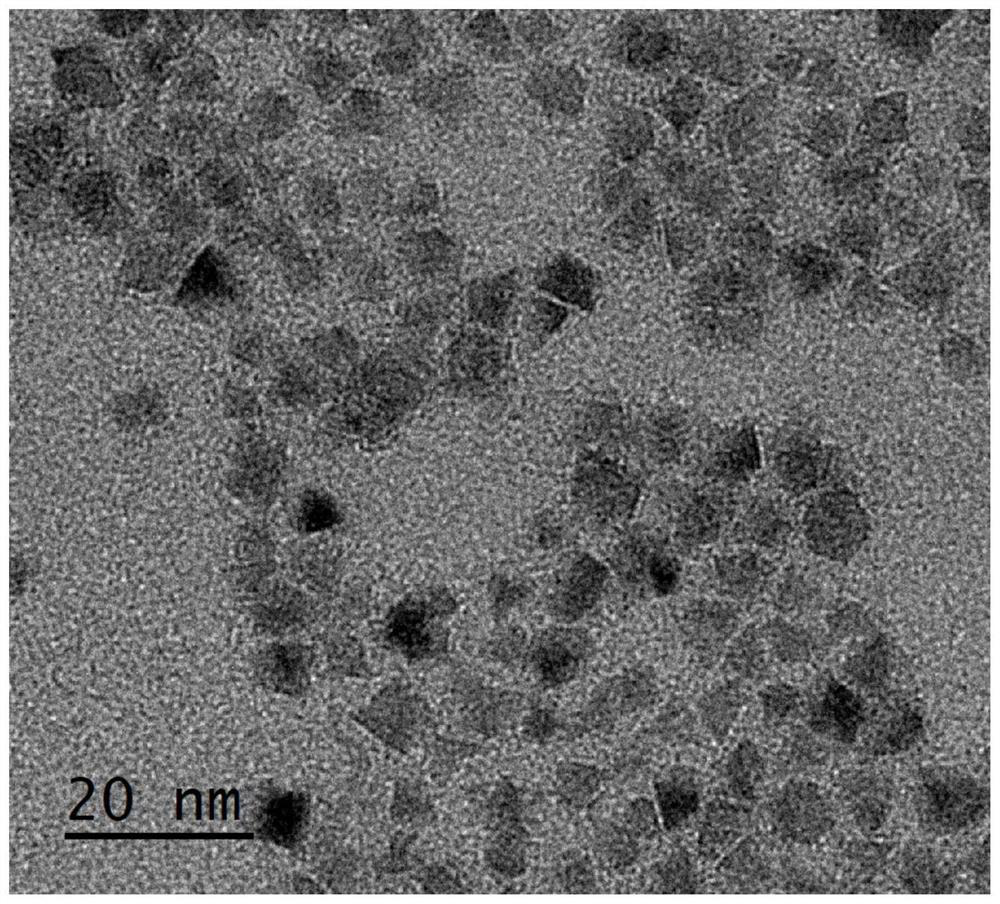

[0027] A copper indium tin selenium / zinc selenide core-shell quantum dot material, the preparation method of which comprises the following steps:

[0028] (1) 0.2mmol copper iodide, 0.2mmol indium acetate, 0.04mmol tin dichloride mixed with 2ml of oleylamine, 2ml of octadecene sulfur mixed into a three-neck flask, heated to 120 °C under a nitrogen atmosphere, and insulation for 10min, and then heated to 190 °C, injected selenium precursor solution, and insulation for 10min, and finally injected 10ml of hexane for reaction quenching, to obtain copper indium tin selenium quantum dots; Among them, the preparation method of selenium precursor solution is: 0.3mmol elemental selenium powder, 0.5ml of oleylamine and 0.3ml of diphenylphosphine mixed, ultrasonic dispersion, that is, to obtain;

[0029] (2) After mixing 0.75mmol of zinc stearate and 5ml of n-octadecene, sonically disperse to dissolve to obtain zinc precursor solution; after mixing 0.6mmol of elemental selenium powder and ...

Embodiment 2

[0033] A copper indium tin selenium / zinc selenide core-shell quantum dot material, the preparation method of which comprises the following steps:

[0034](1) 0.2mmol copper iodide, 0.2mmol indium acetate, 0.04mmol tin dichloride mixed with 2ml of oleylamine, 2ml of octadecene sulfur mixed into the three-neck flask, heated to 110 °C under a nitrogen atmosphere, and insulation for 30min, and then heated to 180 °C, injected into selenium precursor solution, and insulation for 8min, and finally injected 10ml of n-hexane for reaction quenching, to obtain copper indium tin selenium quantum dots; Among them, the preparation method of selenium precursor solution is: 0.3mmol elemental selenium powder, 0.5ml of oleylamine and 0.3ml of diphenylphosphine mixed, ultrasonic dispersion, that is, to obtain;

[0035] (2) After mixing 0.75mmol of zinc stearate and 5ml of n-octadecene, sonically disperse to dissolve to obtain zinc precursor solution; after mixing 0.6mmol of elemental selenium powd...

Embodiment 3

[0039] A copper indium tin selenium / zinc selenide core-shell quantum dot material, the preparation method of which comprises the following steps:

[0040] (1) 0.2mmol copper iodide, 0.2mmol indium acetate, 0.04mmol tin dichloride mixed with 2ml of oleylamine, 2ml of octadecene sulfur mixed into the three-neck flask, heated to 100 °C under a nitrogen atmosphere, and kept warm for 60min, then heated to 170 °C, injected selenium precursor solution, and insulation for 12min, and finally injected 10ml of n-hexane for reaction quenching to obtain copper indium tin selenium quantum dots; Among them, the preparation method of selenium precursor solution is: 0.3mmol elemental selenium powder, 0.5ml of oleylamine and 0.3ml of diphenylphosphine mixed, ultrasonic dispersion, that is, to obtain;

[0041](2) After mixing 0.75mmol of zinc stearate and 5ml of n-octadecene, sonically disperse to dissolve to obtain zinc precursor solution; after mixing 0.6mmol of elemental selenium powder and 4ml...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com