Preparation system and preparation method of dihydroxy polyphenyl ether

A technology of bishydroxy polyphenylene ether and preparation system, achieving the effects of high reactivity, good compatibility and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Preferably: the copper ion is a divalent copper ion or a monovalent copper ion, and other compounds forming complexes are low-carbon organic amines, such as diethylamine, ethylenediamine, etc., inorganic ammonium salts or ammonia water, etc.; The catalyst is one or more of the above-mentioned amine complexes containing copper ions and other compounds.

[0032] Preferably: the tetramethylbisphenol A is directly added to the second reactor in solid form or added to the second reactor as a saturated solution; the amount of tetramethylbisphenol A added is 2,6 dimethylphenol 26%--40% of the quality. Further, the amount of tetramethylbisphenol A added is 35%-37% of the mass of 2,6-dimethylphenol. The volume ratio of the amount of catalyst added to the raw material in the second reactor is 1:23-1:25.

[0033] The present invention will be further described below through specific examples.

[0034] Example 1

[0035] The preparation method of this embodiment is as follows: ...

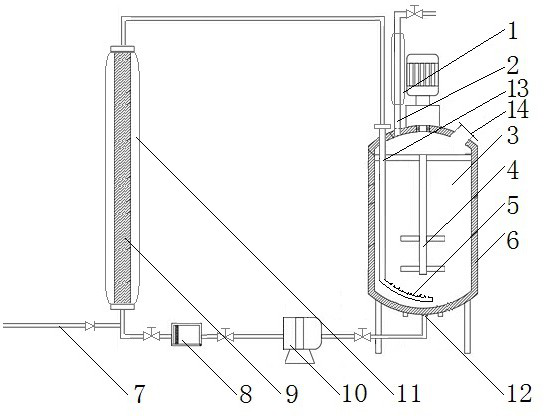

Embodiment 1

In this embodiment, the 60-mesh stainless steel mesh type static mixing type first reactor with an aspect ratio of 150:1 is used, which is processed into a spiral shape with a total length of 3.1 meters and a resistance drop of 0.35 MPa; the second reactor is 80 liters Volumetric stainless steel paddle agitator, the distributor is DN25 stainless steel pipe and drilled 25 holes of Φ3, the direction of liquid injection is towards the stirring paddle; the circulation pump is an explosion-proof stainless steel centrifugal pump with a flow rate of 3 cubic meters per hour.

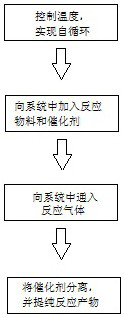

[0045] The preparation method is as follows: first, turn on the water heating system of the reactor, control the temperature of the reactor at 37°C, control and turn on the refrigeration system of the cooler, and the temperature is -22°C; configure 50 liters of 15% (m / m) 2,6 in the preparation tank The toluene solution of dimethylphenol; the solution is pumped into the second reactor from the preparation tank with...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com