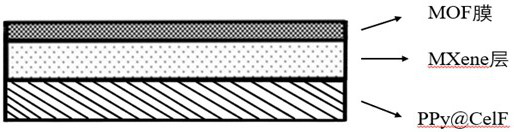

Preparation method of MOF/MXene/PPy-CelF porous nano-material, and product and application of MOF/MXene/PPy-CelF porous nano-material

A nanomaterial, PCN-222 technology, applied in the direction of nanotechnology, hybrid/electric double layer capacitor manufacturing, electrolytic coating, etc., to achieve the effect of improving conductivity, excellent elasticity, and expanding the distance between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] It should be noted that the materials not limited by the present invention indicate that they can be obtained directly in the prior art or by the preparation methods of the prior art; the preparation methods not described in detail in the present invention indicate that they can be obtained by conventional methods that can be obtained by those skilled in the art That's it.

[0037] In order to better illustrate the preparation method, product and application of the present invention, the following specific examples are provided:

[0038] Take 30mL of the prepared MXene nanosheet solution and pour it into a 50mL beaker, immerse the copper plate in the solution as the anode, and the carbon plate as the cathode, directly apply a voltage of 20V / cm for 30s, each deposition is 15s, the interval is 10s, and then take out the copper plate And vacuum drying at room temperature to obtain MXene film;

[0039] Apply the MOF / MXene / PPy@CelF porous nanocomposite prepared in this exam...

Embodiment 1

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com