Treatment system for removing heavy metals in wastewater

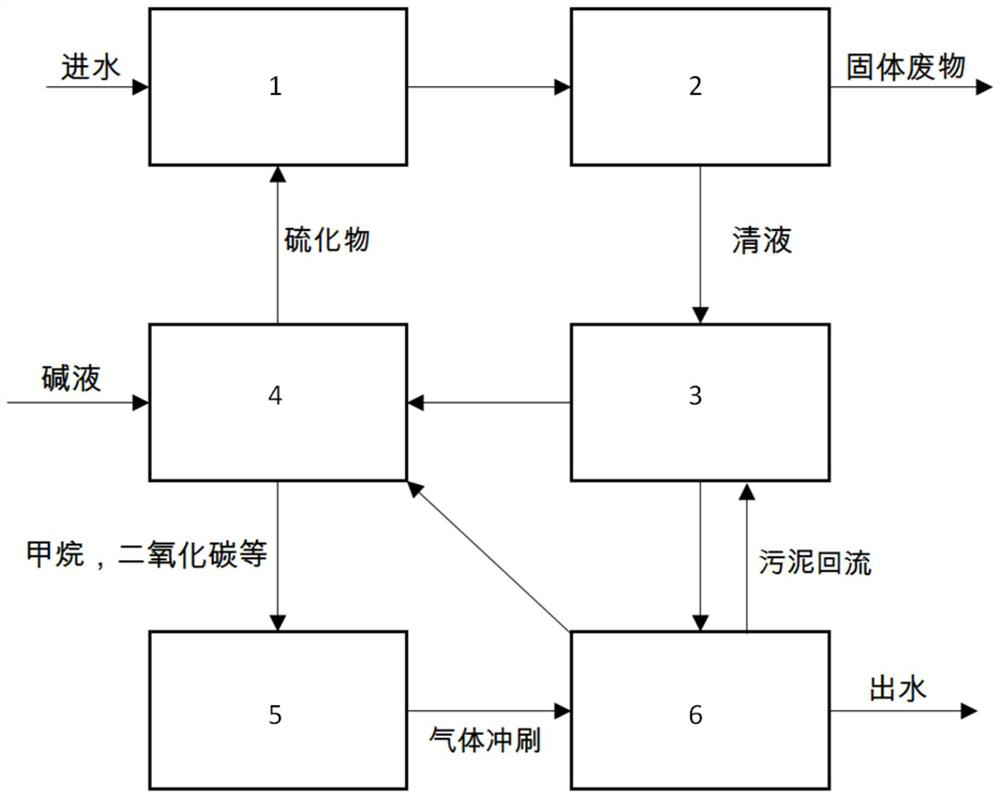

A treatment system and heavy metal technology, applied in water/sewage treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as high cost, long development time of chemical precipitation method, and consumption of large doses of chemicals , to achieve the effect of saving cost, saving dosage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

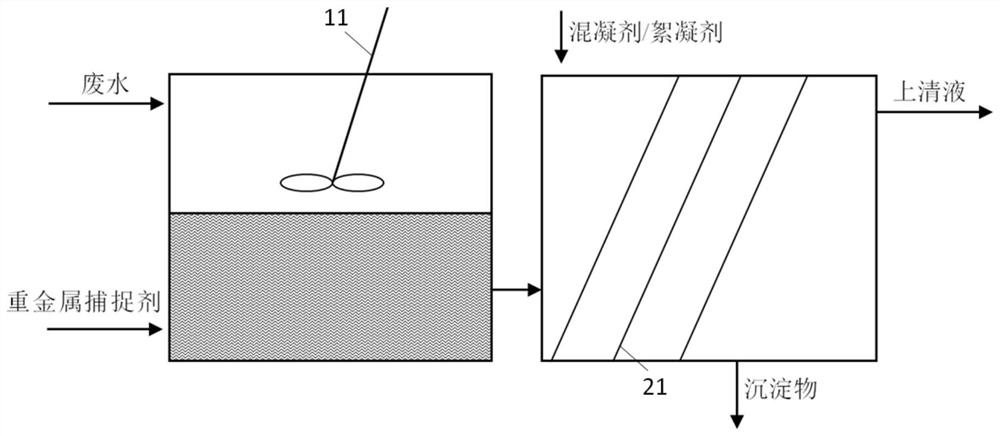

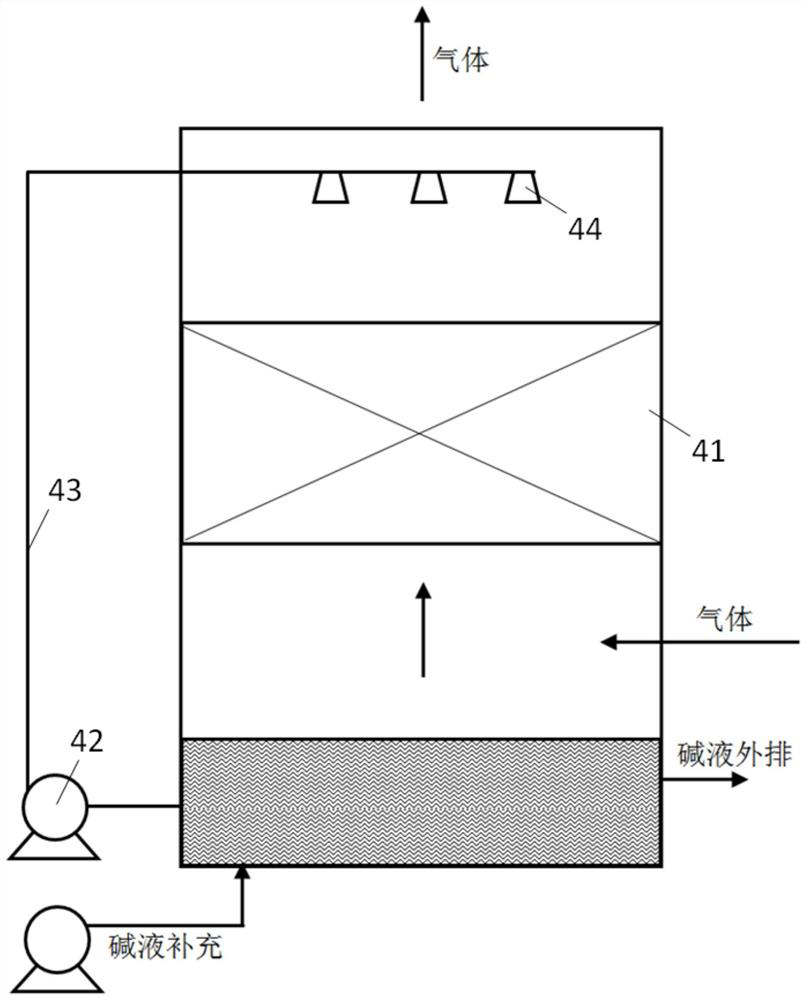

[0045] The influent water quality of a certain electroplating wastewater is shown in Table 1. It has a relatively high sulfate concentration, while the COD concentration is relatively low. COD: sulfate = 1:2 (mass ratio), and the amount of backflow water and the amount of influent water are kept at 1: 1 (volume ratio), add glucose as a carbon source, after mixing COD: sulfate = 2.8 (mass ratio), maintain the anaerobic reactor, the sludge concentration is 10.5g / L, pH is maintained at about 8.2, the reaction The temperature is 32℃, the hydraulic retention time of the anaerobic biochemical reactor is 24 hours, PVDF hollow fiber membrane is used, the membrane pore size is about 0.04μm, the membrane flux is 5L / h, and the aeration intensity is maintained at 60m 3 / m 2 h. The degassing tower uses sodium hydroxide as the lye. The sulfide solution after lye absorption is directly added and mixed with raw water to remove Ni ions and Cu ions. After precipitation of heavy metals in the...

Embodiment 2

[0049] The influent water quality of a certain electroplating wastewater is shown in Table 2, the sulfate concentration is 3400 mg / L, COD: sulfate = 1:1.5 (mass ratio); the amount of reflux water and the influent water are kept at 1:1 (volume ratio), adding Sugar and sugar are added as carbon source. After mixing, COD:sulfate = 3.5 (mass ratio), maintain the anaerobic reactor, the sludge concentration is 8.4g / L, the pH is maintained at about 7.6-8.0, the reaction temperature is 32 ℃, and the anaerobic reactor is maintained. The hydraulic retention time of the oxygen biochemical reactor is 24 hours, PVDF hollow fiber membrane is used, the membrane pore size is about 0.04 μm, the membrane flux is 5L / h, and the aeration intensity is maintained at 60m 3 / m 2 h. The degassing tower uses sodium hydroxide as the lye. The sulfide solution after lye absorption is directly added and mixed with raw water to remove Ni ions and Cr ions. After the heavy metals are precipitated in the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com