Composite nano-material with carbon nano-sheets loaded with carbon nano-tubes in situ as well as preparation method and application of composite nano-material

A technology of composite nanomaterials and carbon nanosheets, which is applied in the field of composite nanomaterials and its preparation in which carbon nanosheets support carbon nanotubes in situ, can solve the problems of high cost and complicated preparation process, and achieve improved electrical conductivity and preparation process. Simple, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention provides a method for preparing a composite nanomaterial with carbon nanosheets supporting carbon nanotubes in situ, comprising the following steps:

[0021] S1: The organic sodium salt or organic acid potassium salt is ball-milled and mixed, and the ball-milled and mixed organic sodium salt or organic acid potassium salt is heat-treated under an inert atmosphere, and filtered, washed and dried after cooling to obtain porous carbon Nano flake powder.

[0022] Preferably, the organic sodium salt is at least one of sodium citrate, sodium ascorbate and sodium succinate; the organic acid potassium salt is at least one of potassium citrate, potassium ascorbate and potassium succinate; The selected organic sodium salt or organic acid potassium salt can be cracked into sodium carbonate or potassium carbonate crystal and coated carbon layer by heat treatment in a high temperature inert atmosphere, and the sodium carbonate or potassium carbonate crystal is ...

Embodiment 1

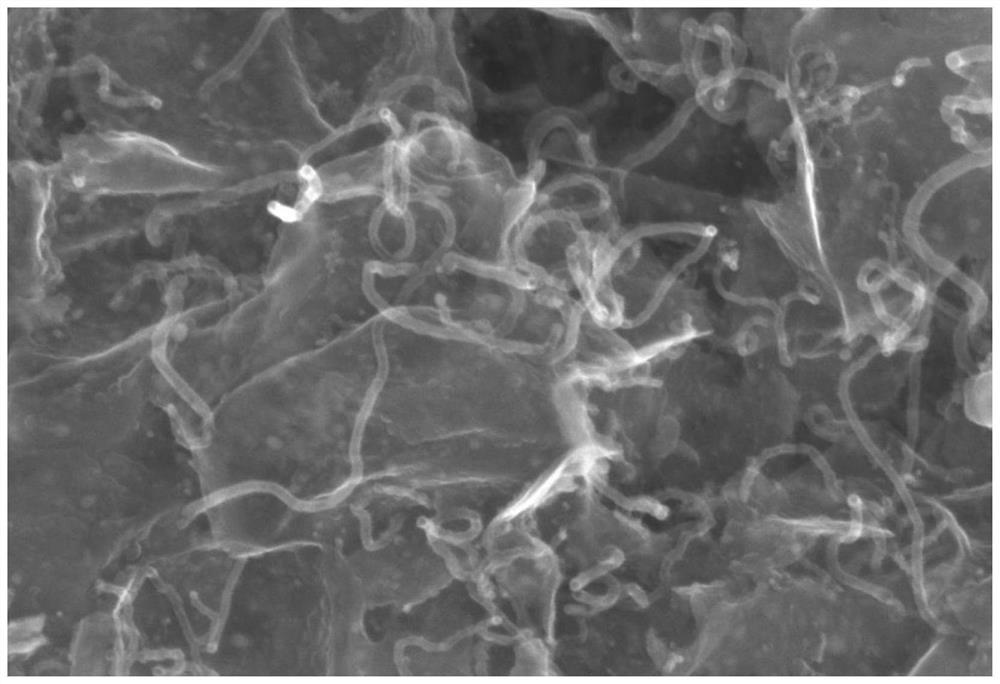

[0037] This embodiment provides a composite nanomaterial in which carbon nanotubes support carbon nanosheets in situ. The composite nanomaterial has a three-dimensional network porous structure and is composed of carbon nanotubes and carbon nanosheets. The carbon nanotubes are grown on the carbon nanosheets in situ. surface. The diameter of the carbon nanotube grown in situ is 10-50 nm, the length is 0.2-5 μm, and the thickness of the carbon nano-sheet is 7-20 nm.

[0038] The present invention also provides a method for preparing the above-mentioned composite nanomaterial of carbon nanotubes in situ supported carbon nanosheets, comprising the following steps:

[0039] (1) Put 60g of sodium citrate into a planetary ball mill for 5h at 450r / min, place it in a tube furnace and heat up to 700°C for 2h under a high-purity Ar atmosphere, filter, wash and dry after cooling to obtain a black three-dimensional Porous carbon nanosheet powder;

[0040] (2) 0.582g of cobalt nitrate was d...

Embodiment 2

[0046] This embodiment provides a composite nanomaterial in which carbon nanotubes support carbon nanosheets in situ. The composite nanomaterial has a three-dimensional network porous structure and is composed of carbon nanotubes and carbon nanosheets. The carbon nanotubes are grown on the carbon nanosheets in situ. surface. The diameter of the carbon nanotube grown in situ is 10-50 nm, the length is 0.2-5 μm, and the thickness of the carbon nano-sheet is 5-10 nm.

[0047] The present invention also provides a method for preparing the above-mentioned composite nanomaterial of carbon nanotubes in situ supported carbon nanosheets, comprising the following steps:

[0048] (1) Put 60g of potassium citrate into a planetary ball mill for 5h at 450r / min, place it in a tube furnace and heat up to 700°C for 2h under a high-purity Ar atmosphere, filter, wash and dry after cooling to obtain a black three-dimensional Porous carbon nanosheet powder;

[0049] (2) 0.582g of cobalt nitrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com