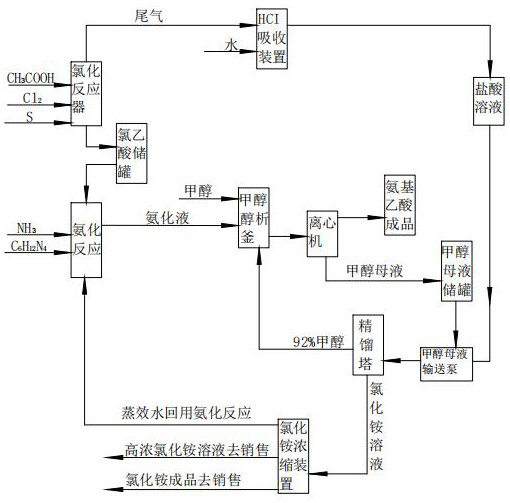

Production process of glycine

A technology for the production of aminoacetic acid, applied in the field of aminoacetic acid production technology, can solve the problems of increased consumption of sulfur and acetic acid raw materials, increased relative load of the concentration section, and large output of ammonium chloride solution, so as to save steam energy Low energy consumption, low raw material consumption and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

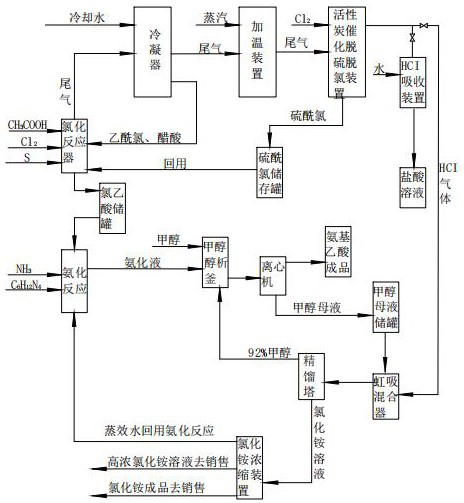

[0036] Depend on figure 2 As can be seen, the present invention comprises the following steps:

[0037] (1) Add acetic acid and chlorine gas into the chlorination reactor to react to generate chloroacetic acid and generate tail gas;

[0038] (2) The chloroacetic acid obtained by the reaction in step (1), ammonia gas and hexamethylenetetramine are added to the ammoniation reactor for reaction to generate an ammoniated solution, and the ammoniated solution is added to a methanol alcohol precipitation kettle for extraction with methanol solution, and the extraction is completed. Then carry out centrifugation to obtain glycine product and methanol mother liquor;

[0039] (3) The tail gas produced in the step (1) enters the cooler for cooling, so that the acetic acid and acetyl chloride in the tail gas are condensed and recycled for the chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com