Wet texturing method for inverted pyramid structure of crystalline silicon

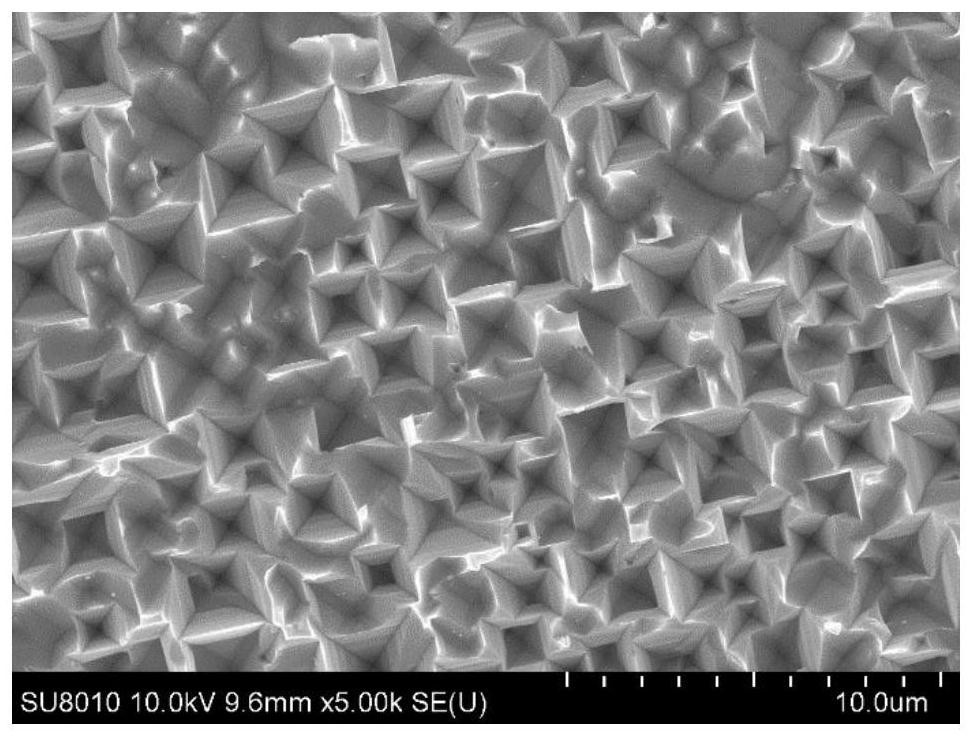

An inverted pyramid and crystalline silicon technology, applied in crystal growth, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc., can solve problems affecting photoelectric conversion efficiency, large inverted pyramid size, large carrier recombination, etc., to achieve improved The effect of photoelectric conversion efficiency, high shape density, and smooth microscopic surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Put the cleaned single crystal silicon wafer into a polytetrafluoroethylene container containing a mixed solution of 0.5mol / L sodium silicate and 10mol / L hydrofluoric acid for 120 minutes at 80°C, and then etch the silicon wafer with Deionized water wash.

Embodiment 2

[0020] Put the cleaned single crystal silicon wafer into a polytetrafluoroethylene container containing a mixed solution of 0.55mol / L sodium silicate and 10mol / L hydrofluoric acid for 120 minutes at 80°C, and then use the etched silicon wafer with Deionized water wash.

Embodiment 3

[0022] Put the cleaned single crystal silicon wafer into a polytetrafluoroethylene container containing a mixed solution of 0.6mol / L sodium silicate and 10mol / L hydrofluoric acid for 120 minutes at 80°C, and then use the etched silicon wafer with Deionized water wash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com