Method for preparing three-dimensional phosphorus-rich compound by combining electrostatic spinning method and low-temperature phosphating method, electrode material and potassium ion battery

An electrospinning, phosphorus-rich compound technology, used in phosphide, battery electrodes, secondary batteries, etc., can solve the problems of large metal phosphide particles, large volume expansion, electrode powdering, etc., to improve electronic conductivity , less energy consumption, and the effect of reducing the use of binders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

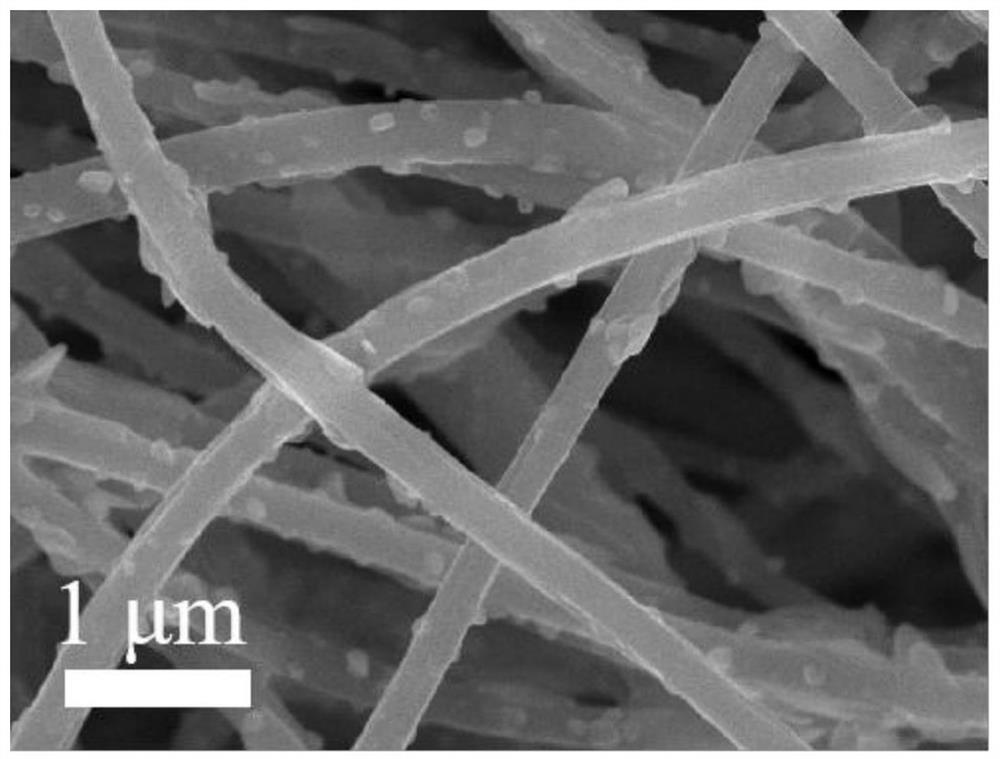

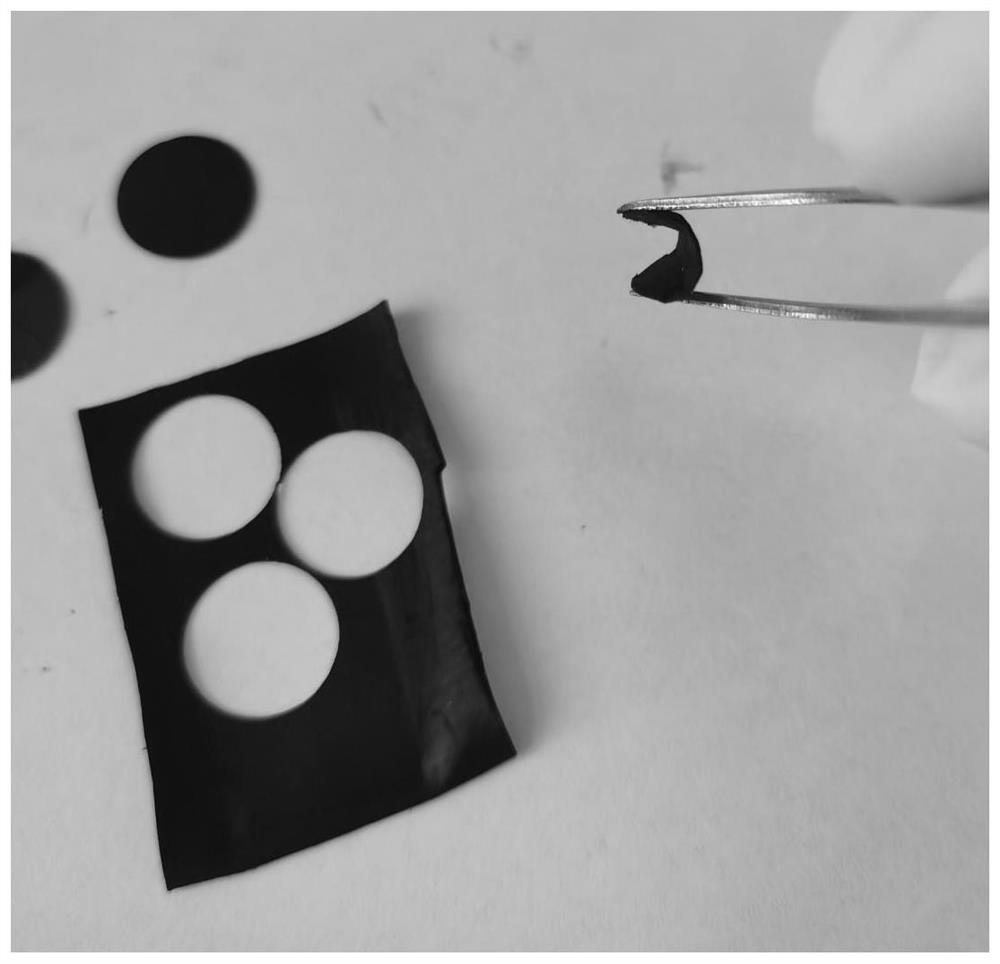

[0035] The negative electrode material prepared by the preparation technology used in the following embodiments of the present invention can effectively alleviate the volume expansion effect of the material during the charging and discharging process, and the interwoven carbon framework can improve the electronic conductivity. The resulting flexible integrated electrode reduces the use of binders and greatly reduces the likelihood of active material peeling off the surface of the current collector.

[0036] The method of combining the electrospinning technology and the low-temperature gas-phase phosphating of sodium hypophosphite in the following examples of the present invention can prepare metal phosphorus-rich compounds with smaller particles, and the method is simple to operate, has strong operability, and can prepare large-area flexible Integrated electrode, suitable for industrial production.

[0037] The following embodiments of the present invention do not have any spe...

Embodiment 1

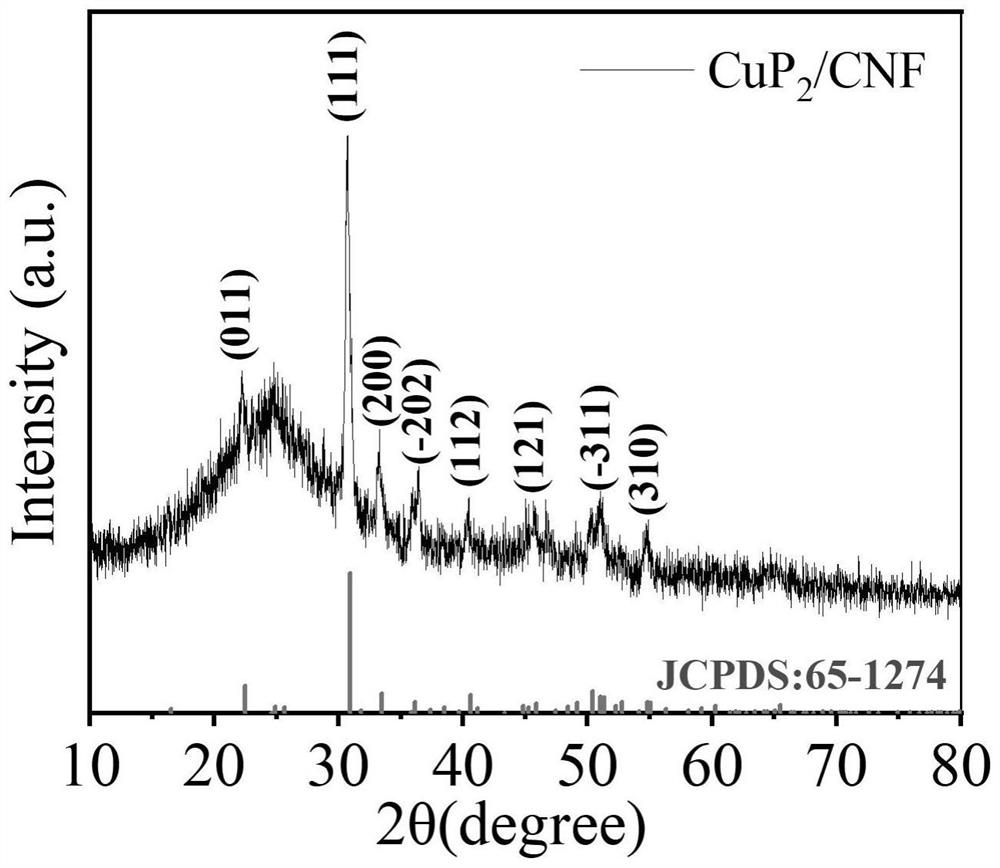

[0043] In this embodiment, a method for preparing a three-dimensional phosphorus-rich compound by combining an electrospinning method with a low-temperature phosphating method includes the following steps:

[0044] a. Precursor preparation: prepare Cu(NO) with a molar concentration ratio of 1:3 3 ) 2 The precursor solution with urea was hydrothermally heated at 120°C for 6 hours to obtain the precursor containing copper element, which was filtered, washed and dried;

[0045] b. Preparation of polymer fibers: PAN and DMF are mixed uniformly in a mass ratio of 1:10 to prepare a preparation solution for electrospinning; the obtained copper-containing precursor is uniformly dispersed in the spinning solution, and the copper-containing precursor and high The mass ratio of polymer PAN is 1:2.5, and the polymer fiber fabric is spun by electrospinning technology according to the injection rate of 0.5mL / L and the high voltage condition of 10kV;

[0046] c. Preparation of three-dimens...

Embodiment 2

[0049] This embodiment is basically the same as the first embodiment, and the special features are:

[0050] In this embodiment, a method for preparing a three-dimensional phosphorus-rich compound by combining an electrospinning method with a low-temperature phosphating method includes the following steps:

[0051] a. Precursor preparation: prepare CoCl with a molar concentration ratio of 1:4 2 The precursor solution with ammonia water was hydrothermally heated at 120 °C for 5 h to obtain the precursor containing cobalt element, which was filtered, washed and dried;

[0052] b. Preparation of polymer fibers: PAN and DMF are mixed uniformly in a mass ratio of 1:10 to prepare a preparation solution for electrospinning; the obtained cobalt-containing precursor is uniformly dispersed in the spinning solution, and the cobalt-containing precursor and high The mass ratio of polymer PAN is 1:3, according to the injection rate of 0.6mL / L and the high voltage condition of 11kV, the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com