Production method of high-pigment carbon black for plastic master batch color paste

A high-pigment carbon black and production method technology, applied in the direction of fibrous filler, dyeing physical treatment, dyeing low-molecular organic compound treatment, etc., can solve problems such as insufficient oxidation, low degree of oxidation on the surface of carbon black, and vegetation destruction. Achieve the effect of long spinning time, good fluidity and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

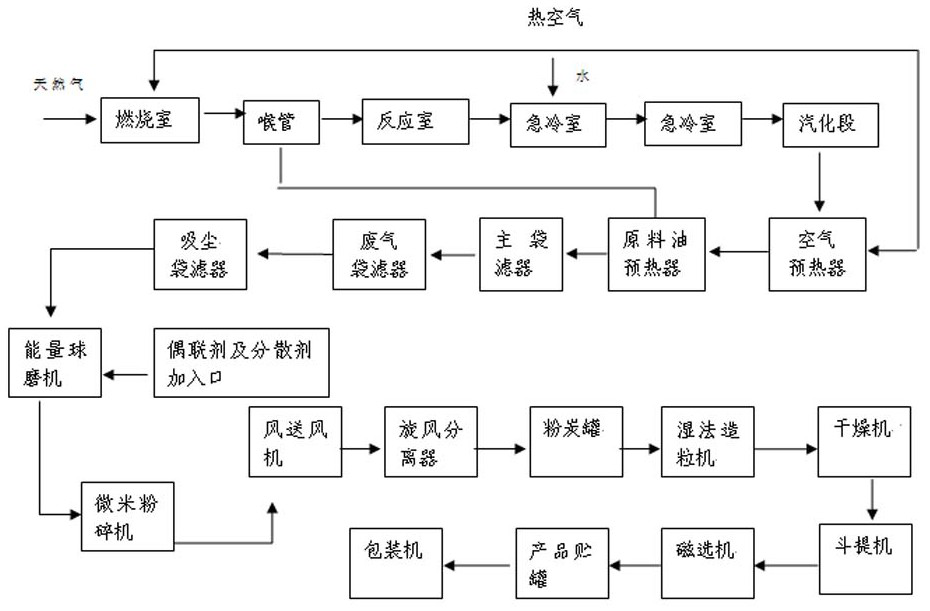

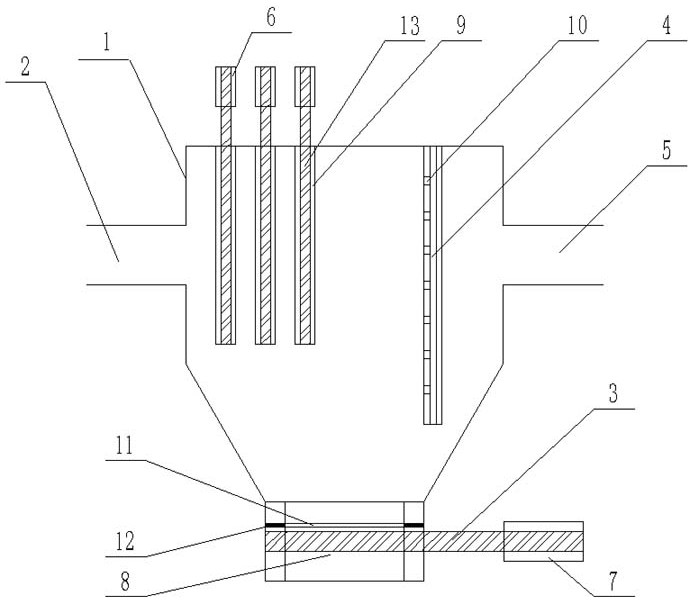

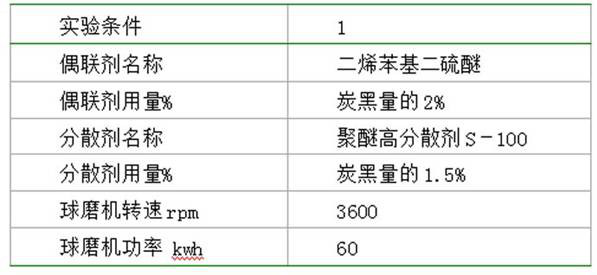

[0025] combined with Figure 1-2 , the present invention is realized in this way, a kind of production method of high-pigment carbon black for plastic master batch color paste, its steps are:

[0026] 1. Raw material oil optimization and secondary processing: The key problem we need to solve is to optimize the raw material oil ratio in the production process, because the color masterbatch and carbon black for color paste require hue, good dispersibility, and low sieve residue content , and the asphaltene content in the oil directly affects the amount of the product sieve residue, and the carbon black produced by the traditional raw materials coal tar and carbon black oil is gray-red phase, which does not meet the requirements of the blue phase, so the process route adopted is the oil and gas method. The process route, the raw material oil is 100% anthracene oil. The specific operation is that the anthracene oil is transported to the unloading tank of the oil tank area by the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com