Ultraviolet reaction hot melt adhesive composition and preparation method thereof

A technology of reaction heat and ultraviolet light, applied in the direction of adhesives, adhesive additives, non-polymer organic compound adhesives, etc., can solve the problem of single functional group types, achieve less side reactions, stable and controllable production process, and broaden the viscosity range. The effect of range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

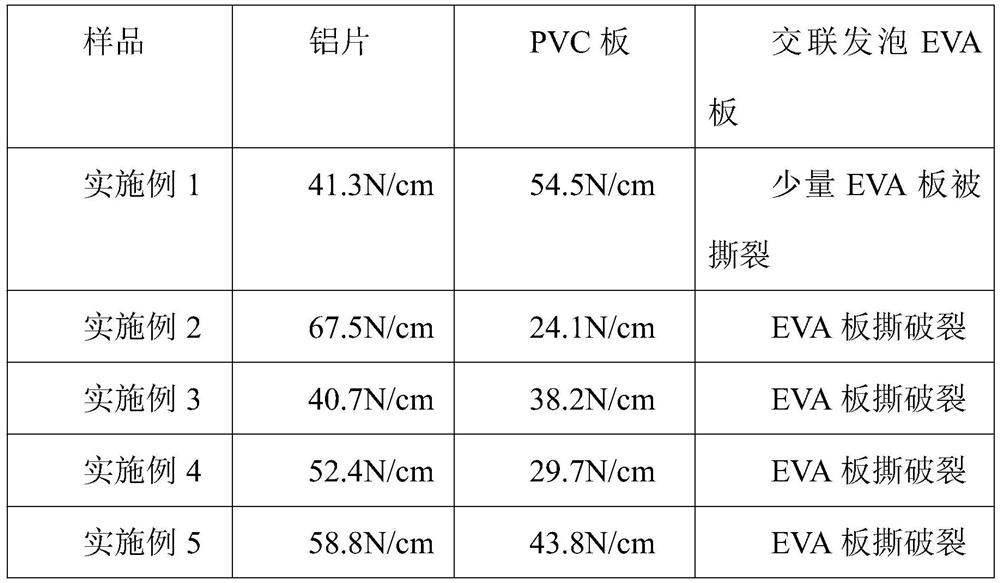

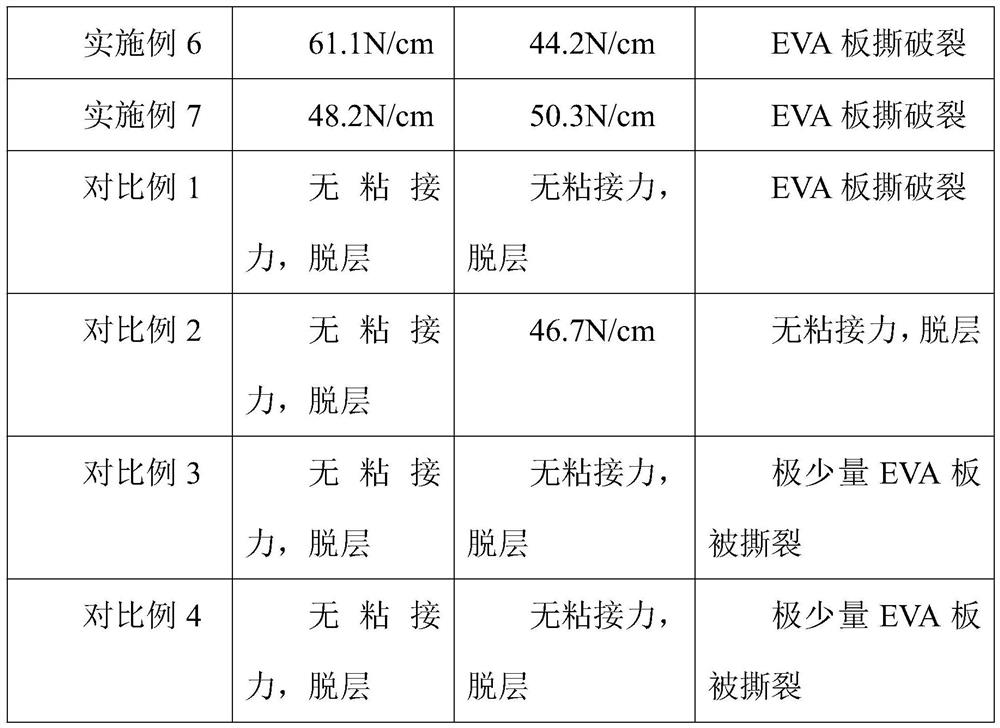

Examples

Embodiment 1

[0047] 10 parts by mass of EVA resin EV40W, 90 parts by mass of TPU resin 1160L, 0.5 part by mass of photoinitiator TPO, 0.1 part by mass of acrylic monomer SR295NS, 0.5 part by mass of functional additive MOES, and 0.5 part by mass of functional additive aliphatic polyurethane resin CN966J75NS are put into high-speed Stir in the stirred tank for about 2 hours, at which time the liquid components are fully absorbed or adhered to the granular resin to complete the premix. The premix is extruded into strands in a twin-screw extruder with a set extrusion temperature of 140°C, and after water cooling and air drying, it enters a 365nm LED UV tunnel furnace, and is irradiated at 10000mj / cm2. grain. The pellets finally produced are passed through a single-screw casting machine with a set temperature of 140°C, and a hot-melt adhesive film with a thickness of 100 microns is obtained after debugging.

Embodiment 2

[0049] 90 parts by mass of EVA resin EV250, 10 parts by mass of TPU resin 1160L, 3 parts by mass of photoinitiator MBF, 2 parts by mass of photoinitiator TPO, 4 parts by mass of acrylic monomer SR285, and 3 parts by mass of functional additive MOES are put into a high-speed stirring tank Stir in medium for about 2 hours, at which time the liquid components are fully absorbed or adhered to the granular resin to complete the premix. The premix is extruded into strands in a twin-screw extruder with a set extrusion temperature of 140°C, and after water cooling and air drying, it enters a 365nm LED UV tunnel furnace, and is irradiated at 10000mj / cm2. grain. The pellets finally produced are passed through a single-screw casting machine with a set temperature of 140°C, and a hot-melt adhesive film with a thickness of 100 microns is obtained after debugging.

Embodiment 3

[0051] 60 mass parts EVA resin EV550, 40 mass parts TPU resin 1160L, 1.5 mass parts photoinitiator MBF, 1.5 mass parts photoinitiator TPO, 2 mass parts photoinitiator accelerator EDB, 2 mass parts acrylic monomer SR285, 0.5 mass parts Part by mass of acrylic monomer SR295, 0.8 part by mass of functional additive MOES, 0.5 part by mass of functional additive aliphatic polyurethane resin CN966J75NS, put into a high-speed stirring tank and stirred for about 2 hours, at which time the liquid component is fully absorbed or adhered to the granular resin, Complete the premix. The premix is extruded into strands in a twin-screw extruder with a set extrusion temperature of 140°C, and after water cooling and air drying, it enters a 365nm LED UV tunnel furnace, and is irradiated at 10000mj / cm2. grain. The pellets finally produced are passed through a single-screw casting machine with a set temperature of 140°C, and a hot-melt adhesive film with a thickness of 100 microns is obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com