Semi-superconducting super-efficient energy-saving motor

An ultra-efficient and superconducting technology, applied in the direction of winding conductive materials, magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve problems such as loss of magnetism, commutator electric corrosion, complex structure, etc. Small power loss, no heat loss, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

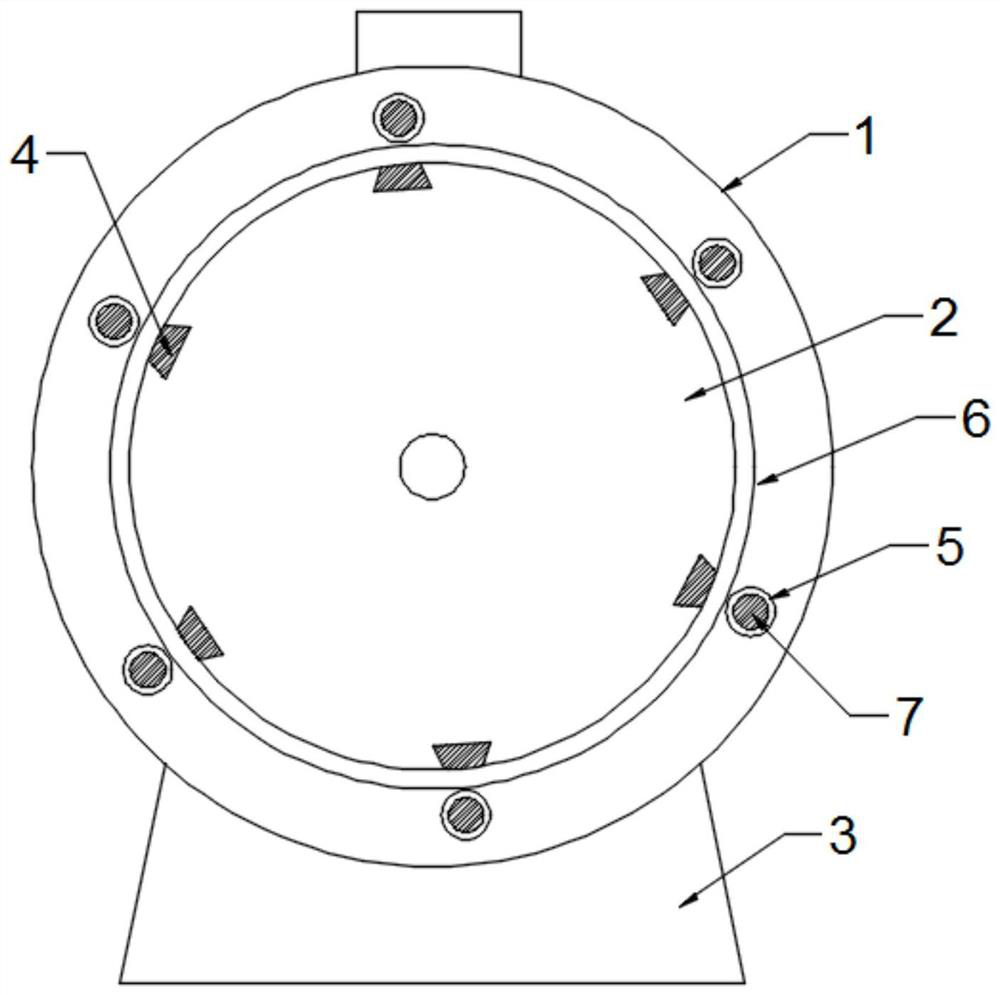

[0027] like figure 1 As shown, this embodiment provides a semi-superconducting super-efficient and energy-saving motor, including a motor casing 1, a rotor main body 2, a stator and a motor base 3, the stator includes a stator main body 6 and a stator winding wound on the stator main body 6, the stator The winding includes a silver-copper alloy material 7 in the middle and a superconducting film 5 wrapped around the silver-copper alloy material 7, and the superconducting film 5 is made of a niobium-titanium composite superconducting material. The niobium-titanium composite superconducting material includes the following components: red copper 69% and niobium-titanium alloy material 31%. The niobium-titanium alloy material includes the following components: metal niobium (Nb) accounts for 50%-55%, and metal titanium (Ti) accounts for 50%-55%. Specifically, in this embodiment, metal niobium (Nb) accounts for 53%, and metal titanium (Ti) accounts for 47%. Of course, metal niobi...

Embodiment 2

[0031] This embodiment is optimized on the basis of the above-mentioned Embodiment 1.

[0032] The rotor main body 2 is uniformly provided with permanent magnets 4 with high temperature resistance and high magnetic flux in the circumferential direction.

[0033] The rotor is equipped with high temperature and high magnetic flux permanent magnets 4 that are not afraid of vibration and can withstand instantaneous high temperatures of 2000°C, so that the output power of the motor will not decrease due to the decay of the magnetic field strength of the rotor with the passage of time. The rotor provides induced excitation current, which can generate strong torque, so the motor is more energy-efficient.

[0034] The rotor adopts permanent magnet 4 with high temperature resistance and high magnetic flux, which is resistant to high temperature, vibration and current impact, and does not require excitation power to provide excitation current to the rotor, so the rotor of this motor has...

Embodiment 3

[0038] This embodiment is optimized on the basis of the above-mentioned Embodiment 2.

[0039] The stator body 6 is made of nanocrystalline alloy material.

[0040] The stator body 6 is a nanocrystalline alloy, which is similar to an oxide with infinite internal resistance, so there is no eddy current loss, iron loss and hysteresis loss which can be ignored, and the motor is more energy efficient.

[0041] The iron core is made of nanocrystalline alloy material. The production process of this material is to spray high-temperature molten iron through a narrow slit to the surface of a high-speed rotating cooling copper roll, and obtain an amorphous alloy material by an extremely cold method. After further appropriate heat treatment process, A nanocrystalline alloy strip with soft magnetic properties is obtained. The initial magnetic permeability of the strip is 110,000-130,000, and the magnetic saturation density is 1.3T, which is many times that of the best quality silicon stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com