Polycarboxylate superplasticizer for reinforcing steel bar sleeve grouting material for prefabricated part and grouting material thereof

A steel sleeve and prefabricated component technology, applied in the field of polycarboxylate superplasticizer and its grouting material, can solve the problems of performance and cost impact, performance and cost impact, etc., to improve mechanical properties, good strength, and system dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

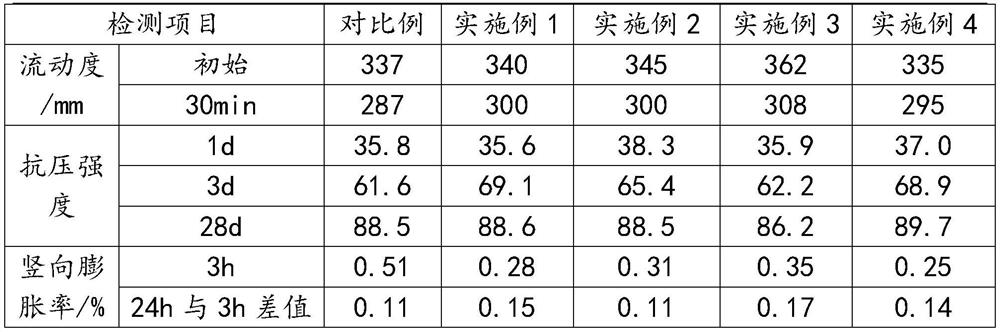

Examples

Embodiment 1

[0059] In parts by weight, weigh 1 part of water-soluble polyether-based polyurethane, 1 part of hydroxyethyl methyl cellulose ether, and 1 part of methyl methacrylate-butadiene-styrene polymer, and use 20° C. Dissolve warm water in the reaction vessel, stir for 20 minutes, keep stirring, add 63 parts of machine-made sand, 7 parts of molybdenum tailing sand, and 20 parts of 100-mesh beer bottle grinding powder in small amounts and several times, stir evenly for 20 minutes, and then add 70 parts of cement with a molecular weight of 30,000 MPEG-AMPS shrinkage-reducing polycarboxylate water-reducing agent with polyethylene glycol monomethyl ether and 2-acrylamido-2-methylpropanesulfonic acid block ratio of 4:1, and stirring for 15min to obtain the Reinforced sleeve dry powder grouting material for prefabricated components.

Embodiment 2

[0061] In parts by weight, weigh 2 parts of water-soluble polyester polyurethane, 2 parts of hydroxypropyl methyl cellulose ether, and 2 parts of acrylonitrile-butadiene-styrene polymer, dissolve them in warm water at a temperature of 30°C In the reaction vessel, stir for 15 minutes, keep stirring, add 68 parts of machine-made sand, 12 parts of molybdenum tailings sand, 25 parts of 150-mesh waste glass grinding powder in small amounts and several times, stir evenly for 25 minutes, and then add 80 parts of cement with a molecular weight of 40,000 and alkene. APEG-MAA shrinkage-reducing polycarboxylate water-reducing agent with a propyl polyoxyethylene ether and methacrylic acid block ratio of 5:1 was stirred for 15 minutes to obtain the steel sleeve dry powder grouting material for prefabricated components.

Embodiment 3

[0063] In parts by weight, weigh 2 parts of water-soluble polyester polyurethane, 2 parts of hydroxypropyl methyl cellulose ether, and 2 parts of acrylonitrile-butadiene-styrene polymer, and dissolve them in warm water at a temperature of 25°C. In the reaction vessel, stir for 20 minutes, keep stirring, add 68 parts of machine-made sand, 12 parts of molybdenum tailings sand, and 25 parts of 150-mesh waste glass grinding powder in small amounts and several times, stir evenly for 20 minutes, and then add 80 parts of cement with a molecular weight of 50,000 and A. TPEG-MA shrinkage-reducing polycarboxylate water-reducing agent with a block ratio of allyl polyoxyethylene ether and methacrylamide of 5:1 was stirred for 20 minutes to obtain the dry powder grouting material for steel sleeves for prefabricated components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com