Hemicellulose-based hydrogel based on eutectic solvent as well as preparation method and application of hemicellulose-based hydrogel

A deep eutectic solvent and hemicellulose technology, applied in the production of bulk chemicals, etc., can solve the problems of long process flow, energy consumption, lack of functionality, etc., and achieve the effect of simplifying the preparation process and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

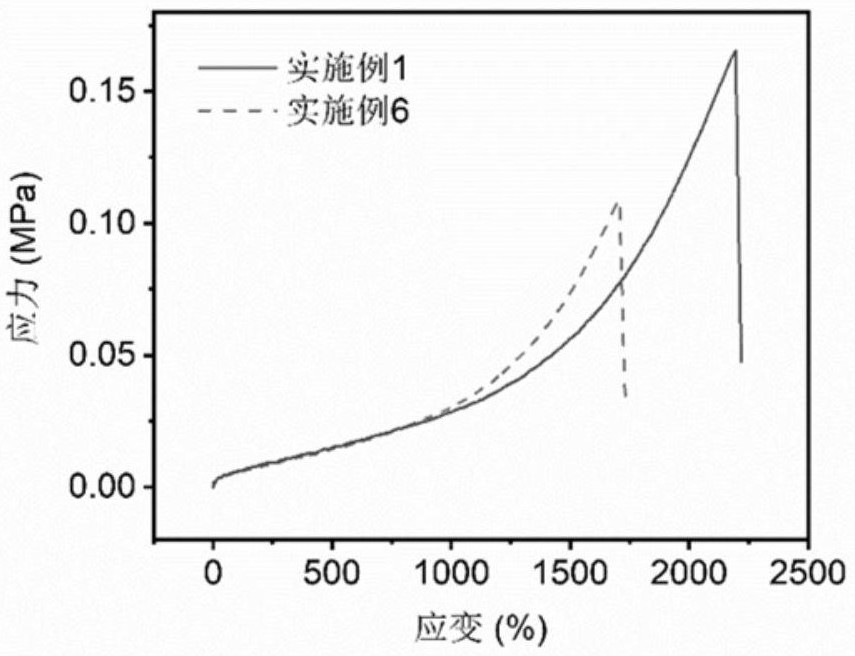

Embodiment 1

[0018] 1) Mix choline chloride and imidazole according to the molar ratio of 3:7, then heat up to 80 °C in magnetic stirring and dissolve for 4 hours to obtain a clear solution, freeze-dry to obtain choline chloride / imidazole deep eutectic solvent for subsequent use ;

[0019] 2) Drying the hemicellulose in a blast drying oven to remove moisture to obtain dry hemicellulose for later use;

[0020] 3) Mix the dry hemicellulose described in step 2) with the choline chloride / imidazole deep eutectic solvent prepared in step 1), raise the temperature to 80 °C in magnetic stirring and fully dissolve to obtain hemicellulose and low The hemicellulose-deep eutectic solvent mixture with a mass-to-volume ratio of the eutectic solvent of 35 mg / mL;

[0021] 4) Combine acrylamide, N,N′-methylenebisacrylamide and 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone with deionized Mixing with water, the concentration of acrylamide in the obtained solution is 5.6 mol / L, and the concen...

Embodiment 2

[0023] 1) Mix choline chloride and oxalic acid in a molar ratio of 1:1, then heat up to 100 °C in magnetic stirring to dissolve for 5 hours to obtain a clear solution, and freeze-dry to obtain a choline chloride / oxalic acid deep eutectic solvent spare;

[0024] 2) Drying the hemicellulose in a blast drying oven to remove moisture to obtain dry hemicellulose for later use;

[0025] 3) Mix the dry hemicellulose described in step 2) with the choline chloride / oxalic acid deep eutectic solvent prepared in step 1), raise the temperature to 100 °C in magnetic stirring and fully dissolve to obtain hemicellulose and low A hemicellulose-deep eutectic solvent mixture with a mass-to-volume ratio of eutectic solvent of 25 mg / mL;

[0026] 4) Combine acrylamide, N,N′-methylenebisacrylamide and 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone with deionized Mixing with water, the concentration of acrylamide in the obtained solution is 5.6 mol / L, and the concentration of N,N′-met...

Embodiment 3

[0028] 1) Mix choline chloride and lactic acid in a molar ratio of 1:10, then heat up to 60 °C in magnetic stirring to dissolve for 5 hours to obtain a clear solution, and freeze-dry to obtain a choline chloride / lactic acid deep eutectic solvent spare;

[0029] 2) Drying the hemicellulose in a blast drying oven to remove moisture to obtain dry hemicellulose for later use;

[0030] 3) Mix the dry hemicellulose described in step 2) with the choline chloride / oxalic acid deep eutectic solvent prepared in step 1), raise the temperature to 100 °C in magnetic stirring and fully dissolve to obtain hemicellulose and low A hemicellulose-deep eutectic solvent mixture with a mass-to-volume ratio of eutectic solvent of 25 mg / mL;

[0031] 4) Combine acrylamide, N,N′-methylenebisacrylamide and 2-hydroxy-2-methyl-1-[4-(2-hydroxyethoxy)phenyl]-1-propanone with deionized Mixing with water, the concentration of acrylamide in the obtained solution is 5.6 mol / L, and the concentration of N,N′-met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com