Modified nano-microsphere, PC/PET composite material and preparation method of modified nano-microsphere and PC/PET composite material

A nano-microsphere and modification technology, which is applied in the field of nano-materials and polymer materials, can solve the problems of affecting the fluidity and gloss of composite materials, restricting popularization and application, and low mechanical strength, so as to improve the transmittance of visible light and wide Application prospect, effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

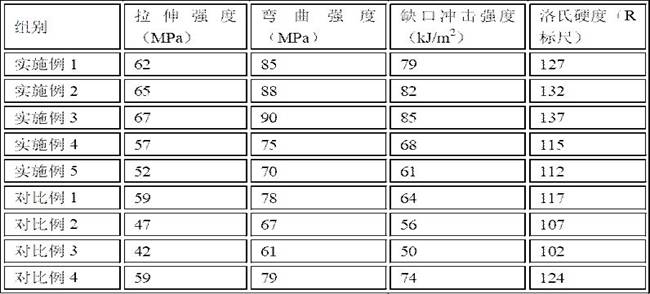

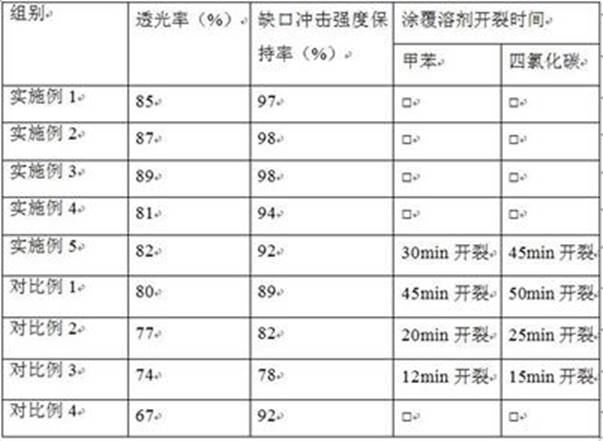

Embodiment 1

[0031] This embodiment provides a PC / PET composite material:

[0032] Composition of raw materials (parts by weight): 60 parts of PC, 12 parts of PET, 0.5 part of composite compatibilizer, and 0.1 part of transparent agent sorbitol. The composite compatibilizer includes modified silica / polydopamine / polystyrene porous hollow nanospheres and maleic anhydride grafted polyethylene, with a mass ratio of 3:7.

[0033] The preparation method includes the following steps:

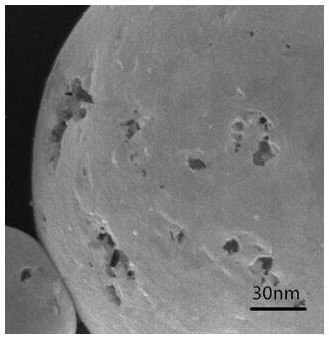

[0034] (1) Preparation of modified silica / polydopamine / polystyrene porous hollow nano-microspheres, the specific method is as follows:

[0035] S1. Preparation of polystyrene porous hollow nano-microspheres: mix and dissolve 0.05g benzoyl peroxide and 1g styrene monomer, add 0.2g hydrophilic monomer methyl methacrylate and 0.02g hexadecyl Trimethylammonium bromide, after stirring and mixing evenly, add 5g of an aqueous solution containing 3wt% PVA, and ultrasonically disperse at 1000W for 20min to obtain a suspen...

Embodiment 2

[0042] This embodiment provides a PC / PET composite material:

[0043] Composition of raw materials (parts by weight): 80 parts of PC, 32 parts of PET, 2 parts of composite compatibilizer, 0.3 part of transparent agent triaryl phosphate, and 0.5 part of antioxidant triphenyl phosphite. The composite compatibilizer includes modified silica / polydopamine / polystyrene porous hollow nano-microspheres and maleic anhydride grafted polyethylene, with a mass ratio of 5:7.

[0044] The preparation method includes the following steps:

[0045] (1) Preparation of modified silica / polydopamine / polystyrene porous hollow nano-microspheres, the specific method is as follows:

[0046] S1. Preparation of polystyrene porous hollow nano-microspheres: mix and dissolve 0.1g dicumyl peroxide and 2g styrene monomer, add 0.4g hydrophilic monomer methyl methacrylate and 0.07g isooctane , after stirring and mixing evenly, add 10g of an aqueous solution containing 5wt% PVA, 1000W ultrasonic dispersion for...

Embodiment 3

[0053] This embodiment provides a PC / PET composite material:

[0054] Composition of raw materials (parts by weight): 70 parts of PC, 18 parts of PET, 1 part of composite compatibilizer, 0.2 part of transparent agent sorbitol, 0.2 part of antioxidant 2,6-di-tert-butyl-4-cresol. The composite compatibilizer includes modified silica / polydopamine / polystyrene porous hollow nano-microspheres and maleic anhydride grafted polyethylene, with a mass ratio of 4:7.

[0055] The preparation method includes the following steps:

[0056] (1) Preparation of modified silica / polydopamine / polystyrene porous hollow nano-microspheres, the specific method is as follows:

[0057] S1. Preparation of polystyrene porous hollow nano-microspheres: Mix and dissolve 0.07g tert-butyl peroxy tert-valerate and 1.5g styrene monomer, add 0.3g hydrophilic monomer methyl methacrylate and 0.05g g PEO20-PPO70-PEO20, after stirring and mixing uniformly, add 7g aqueous solution containing 4wt% PVA, 1000W ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com