Preparation method of pure titanium surface modified nano titanium dioxide film layer

A technology for surface modification of nanometer and nanometer titanium dioxide, applied in the field of medical titanium alloy, can solve the problems of single surface film layer, insufficient stability, low bonding strength between film and substrate, etc. corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

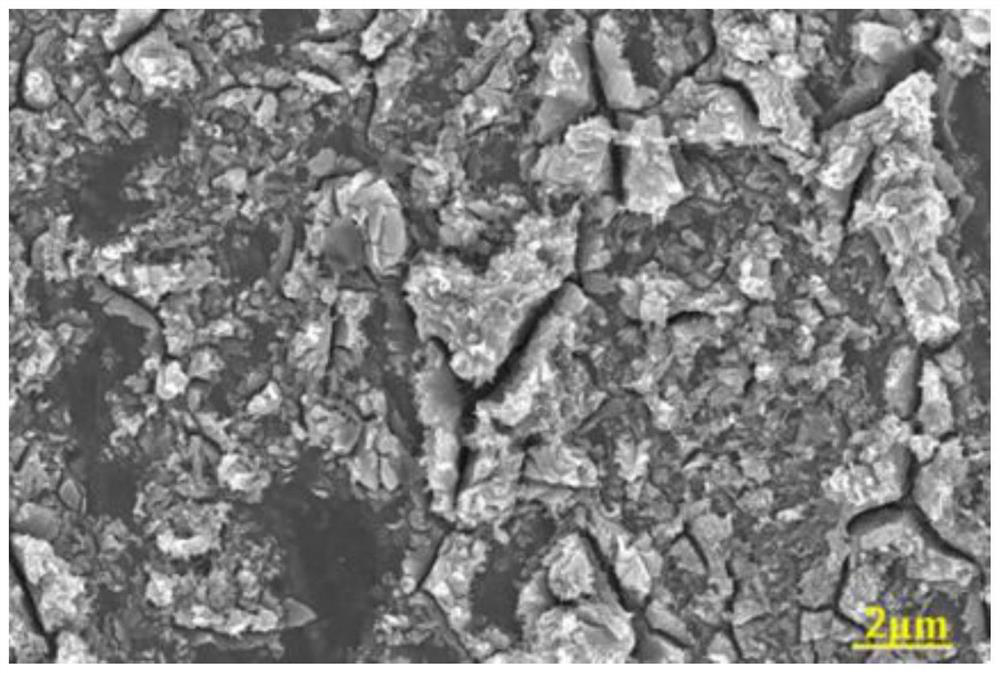

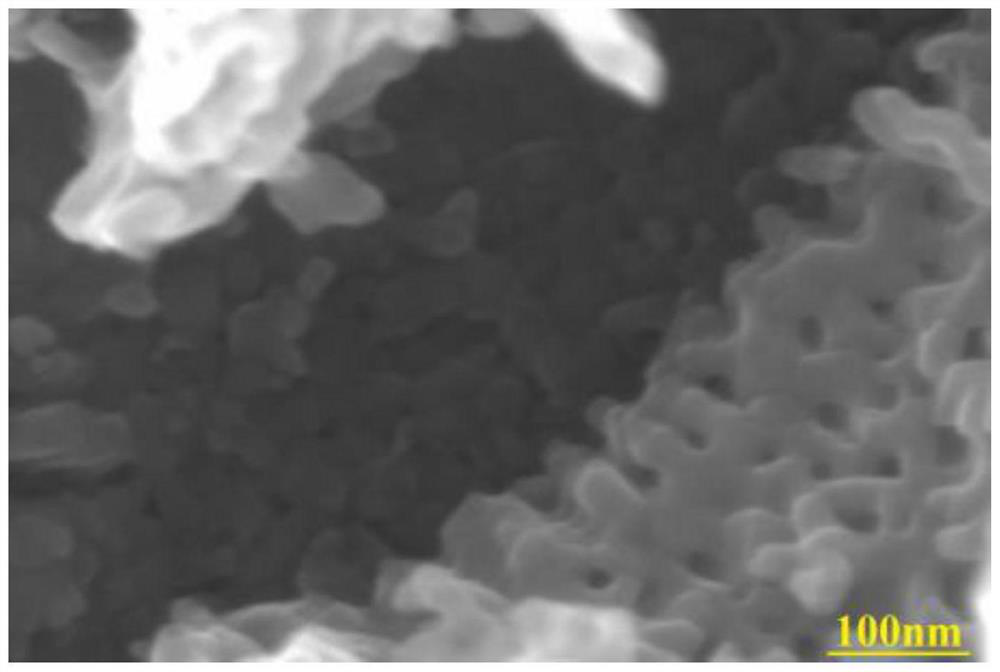

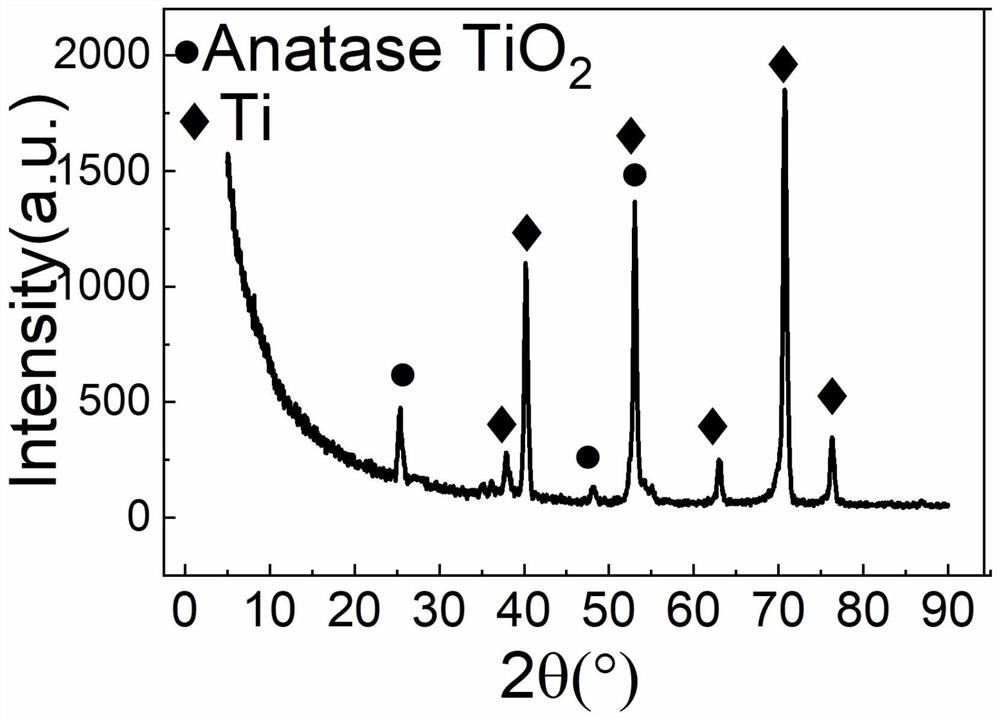

Image

Examples

Embodiment 1

[0029] (1) The preparation method is as follows:

[0030] 1. Soak the titanium substrate in a mixed solution of hydrochloric acid and sulfuric acid with a mass ratio of 1:3 for 30 minutes to remove the oxide scale on the surface, then rinse it with a large amount of deionized water, and then ultrasonically clean it in absolute ethanol for 15 minutes. The surface was blown dry with high-purity nitrogen. Then, the titanium substrate is used as the anode and the graphite electrode is used as the cathode to be connected to the two poles of the DC voltage stabilized power supply respectively, and the voltage of the power supply is adjusted to 20V and the current to -1 HNO 3 In the solution, the titanium substrate was anodized for 15 minutes while magnetic stirring, and rinsed with a large amount of deionized water after taking it out; then the anodized titanium plate was placed in a furnace, preheated at 70 °C for 2 hours, and then heated to calcined at 490 °C for 3 hours, and th...

Embodiment 2

[0041] The titanium substrate was soaked in a mixed solution of hydrochloric acid and sulfuric acid with a mass ratio of 1:3 for 40 minutes to remove the oxide scale on the surface, then rinsed with a large amount of deionized water, and then ultrasonically cleaned in absolute ethanol for 20 minutes. Pure nitrogen blows the surface dry. Then connect the titanium substrate as the anode and the graphite electrode as the cathode to the two poles of the DC stabilized power supply respectively, adjust the power supply voltage to 15V, the current to 0.5A, and the current to be 0.05mol·L. -1 HNO 3 In the solution, the titanium substrate was anodized for 20 minutes while magnetic stirring, and then rinsed with a large amount of deionized water. calcined at 490 °C for 3.5 hours, and then calcined the titanium sheet at 0.05 mol·L -1 The acetaminophen solution was soaked in ethanol solution for 4 hours, then taken out and calcined in a furnace at 120 °C for 30 minutes, and then at 0.01...

Embodiment 3

[0043] Soak the titanium substrate in a mixed solution of hydrochloric acid and sulfuric acid with a mass ratio of 1:3 for 30 minutes to remove the oxide scale on the surface, then rinse it with a large amount of deionized water, then ultrasonically clean it in absolute ethanol for 20 minutes, and use high Pure nitrogen blows the surface dry. Then, the titanium substrate is used as the anode and the graphite electrode is used as the cathode to be connected to the two poles of the DC voltage stabilized power supply respectively, and the voltage of the power supply is adjusted to 20V and the current to -1 HNO 3 In the solution, the titanium substrate was anodized for 25 minutes while magnetic stirring, and then rinsed with a large amount of deionized water. calcined at 480 °C for 3.5 hours, and then calcined the titanium sheet at 0.05 mol·L -1 The acetaminophen solution was soaked in ethanol for 3 hours, then taken out and calcined in a furnace at 110 °C for 30 minutes, follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com