Sulfuration-free fresh bamboo shoot preservation technology

A technology of fresh bamboo shoots and technology, which is applied in the field of non-sulfurized fresh bamboo shoots preservation technology, can solve the problems of 1-2 days, uncontrollable production time, difficult curing of desulfurization process time, etc., so as to save the time of heating up and pressure Cooling time for depressurization and temperature reduction, saving time cost and storage space cost, and avoiding the effect of the risk of sulfur-containing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

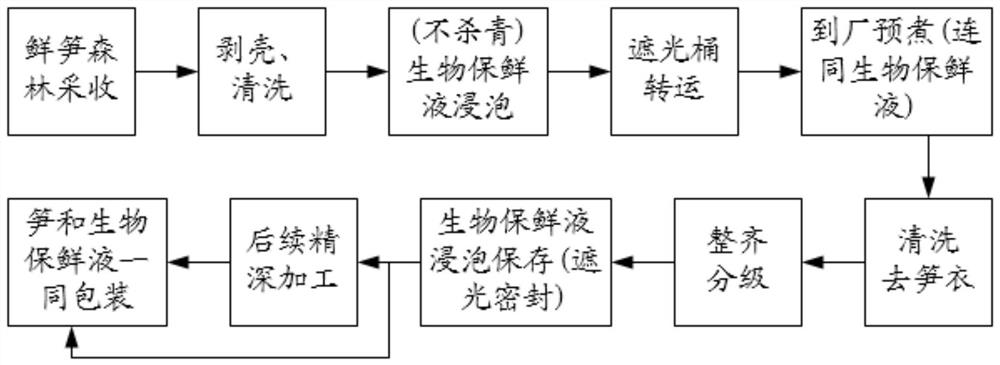

[0049] like figure 1 As shown in the figure, the preservation process of the non-sulfide fresh bamboo shoots includes the following steps:

[0050] S1. After fresh bamboo shoots are harvested, peel and clean fresh bamboo shoots at the site or nearby; the site or nearby referred to here is the processing location set according to the fresh bamboo shoots harvesting environment (mostly mountain forests), such as beside the road at the foot of the mountain To establish a simple temporary processing point, the cost is low, and the fresh bamboo shoots can also be processed conveniently in a short distance, so that the fresh bamboo shoots after harvesting can be easily moved, and then transported to the bamboo shoot processing plants and other factories in a long distance after preliminary treatment;

[0051] S2. Put the cleaned fresh bamboo shoots into a container equipped with a sulfur-free biological fresh-keeping liquid to soak, and transfer them to a bamboo shoot processing plan...

Embodiment 2

[0058] The difference between this example and Example 1 is that the components of the non-sulfurized biological preservative used are different. The non-sulfided biological preservative in this embodiment includes the following components by weight:

[0059] ε-polylysine hydrochloride 2-8 parts, nisin 1-10 parts, sodium citrate 20-100 parts, sodium chloride 200-600 parts, D-sodium erythorbate 2-40 parts.

[0060] The pH of the sulfur-free biological fresh-keeping liquid prepared by adding pure water to the sulfur-free biological fresh-keeping agent is neutral. The ratio of the sulfur-free biological preservative to pure water is 1:30-150.

[0061] In this embodiment, the sulfur-free biological preservative can also add at least one of chitosan, agar-oligosaccharide, protamine, and bamboo fungus extract as biological antibacterial components in the formula according to actual application requirements, such as a The added proportions by weight are: 2-10 parts of chitosan, 2-8 ...

Embodiment 3

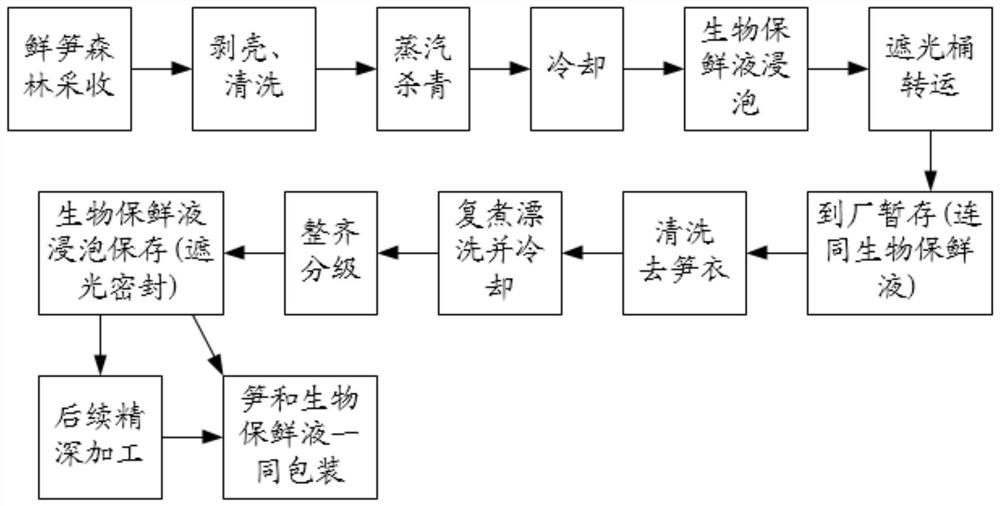

[0063] like figure 2 As shown in the figure, the preservation process of the non-sulfide fresh bamboo shoots includes the following steps:

[0064] S1. After the fresh bamboo shoots are harvested, peel and clean the fresh bamboo shoots on site or nearby;

[0065] S2. The fresh bamboo shoots are treated with steam at or near the peeling and cleaning treatment site;

[0066] S3, the fresh bamboo shoots after the steam-fixing treatment are cooled and soaked in a container equipped with a sulfur-free biological fresh-keeping liquid, and transferred to a bamboo shoot processing plant in the shade; wherein, the volume ratio of the bamboo shoots to the sulfur-free biological fresh-keeping liquid during soaking is 1 :1-2;

[0067] S4. After the fresh bamboo shoots arrive at the factory, they are temporarily stored together with the sulfur-free biological fresh-keeping liquid, and a corresponding amount of bamboo shoots are taken to wash and remove the bamboo shoots according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com