Iron-containing oxide coated sulfur-doped expanded graphite/silicon electrode material and preparation method thereof

A technology of expanded graphite and electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of easy exposure, large volume of silicon carbon particles and silicon atoms, and achieve enhanced lithium storage capacity, inhibition of volume expansion, and unique electrical properties. Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

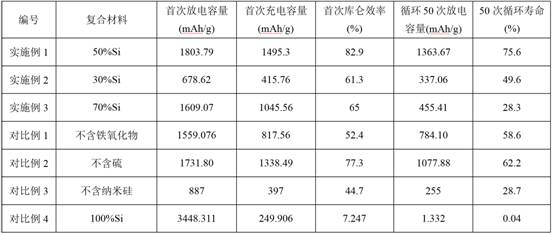

Examples

Embodiment 1

[0037] This embodiment provides an iron oxide-coated sulfur-doped expanded graphite / silicon electrode material, and the preparation process specifically includes the following steps:

[0038] (1) Mix and grind 100 mg of ferrocene and 100 mg of expandable graphite for 15 minutes, stir evenly, and heat and expand at a high temperature of 1200 °C in a high-temperature expansion furnace for 0.5 h to obtain expanded graphite coated with iron oxide;

[0039] (2) Weigh 100 mg of thiourea and 100 mg of the iron oxide-coated expanded graphite obtained in step (1), grind them uniformly with a mortar, and transfer them into a ceramic boat, then put them into a tube furnace, and vacuumize them. Filled with argon gas at an atmospheric pressure for protection, and heated in a closed tube furnace until the temperature in the furnace reached 1000 ° C and then kept for 30 minutes, and then cooled to room temperature with the furnace to obtain iron oxide-coated sulfur-doped expanded graphite;

...

Embodiment 2

[0045] The content of an iron oxide-coated sulfur-doped expanded graphite / silicon electrode material is basically the same as that of Example 1, except that 30 mg of nano-silicon is added in the preparation step (2), and 70 mg of the electrode material obtained in the step (2) is added. In the iron oxide-coated sulfur-doped expanded graphite, the nano-silicon accounts for 30 wt % of the mass sum of both the nano-silicon and the iron oxide-coated sulfur-doped expanded graphite.

[0046] The content of an electrode sheet is basically the same as that of Embodiment 1, except that the electrode material attached to the conductive copper foil substrate is the iron oxide-coated sulfur-doped expanded graphite prepared by the above preparation method of this embodiment. / Silicon electrode material.

[0047] The content of a lithium ion battery is basically the same as that of Example 1, except that the negative electrode is the electrode sheet prepared in this example.

Embodiment 3

[0049] The content of an iron oxide-coated sulfur-doped expanded graphite / silicon electrode material is basically the same as that of Example 1, except that 70 mg of nano-silicon is added in the preparation step (2), and 30 mg of the electrode material obtained in the step (2) is added. In the iron oxide-coated sulfur-doped expanded graphite, the nano-silicon accounts for 70 wt % of the sum of the mass of the nano-silicon and the iron oxide-coated sulfur-doped expanded graphite.

[0050] The content of an electrode sheet is basically the same as that of Embodiment 1, except that the electrode material attached to the conductive copper foil substrate is the iron oxide-coated sulfur-doped expanded graphite prepared by the above preparation method of this embodiment. / Silicon electrode material.

[0051] The content of a lithium ion battery is basically the same as that of Example 1, except that the negative electrode is the electrode sheet prepared in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com