Preparation method of fermented rice flour rich in gamma-aminobutyric acid

A production method and technology of fermented rice flour, applied in the food field, can solve the problems of lack of health care function, insufficient rice flavor, low content of gamma-aminobutyric acid, etc., and achieve the effects of moderate molecular weight, product safety and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of γ-aminobutyric acid-rich fermented rice flour, comprising the following steps:

[0041] (1) Preparation of rice milk solution: Soak Northeast Japonica rice in cold boiled water at 25°C for 24 hours. After draining the water, add sterile water at a ratio of 5mL:1g (that is, sterile water and drained rice 5mL:1g). into rice milk, and then go through a colloid mill to obtain a rice milk solution with smaller particles;

[0042] (2) Fermentation culture: add L-sodium glutamate to the obtained rice milk solution, the volume percentage of L-sodium glutamate and rice milk solution is 1.0%, and then inoculate Lactobacillus plantarum ( Lactobacillus plantarum ), the inoculum of Lactobacillus plantarum was 10 7 cfu / mL, fermented and cultured at 25°C for 72 hours to obtain fermented rice milk rich in high γ-aminobutyric acid;

[0043] (3) Preparation of fermented rice flour: the obtained fermented rice milk is drained, dried in a vacuum, and pulverized. ...

Embodiment 2

[0046] In step (2), the following Lactobacillus plantarum is used for fermentation culture.

[0047] The information of the Lactobacillus plantarum has been disclosed in the following authorized invention patents, the patent number is ZL201910868832.8, the publication number is CN110592151B, and the patent name is: lactic acid bacteria produce high γ-aminobutyric acid fermentation broth and its application in cosmetics application.

[0048] The public can obtain the Lactobacillus plantarum ( Lactobacillus plantarum ), the strain preservation number is CGMCCNO.11379.

[0049] Other steps are the same as in Example 1.

Embodiment 3

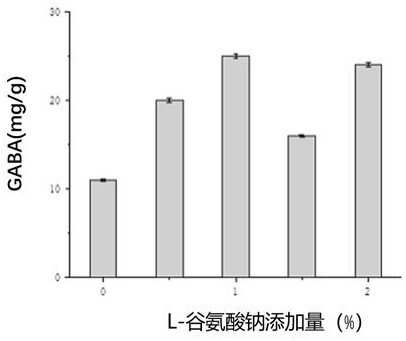

[0050] Example 3 Detecting the effect of sodium L-glutamate addition on the γ-aminobutyric acid yield of fermented rice flour

[0051]The addition amount (volume percentage) of sodium L-glutamate in Example 2 was adjusted to 0, 0.5%, 1%, 1.5%, and 2%, respectively. Others are the same as in Example 2. The effects of different amounts of sodium L-glutamate on the production of γ-aminobutyric acid in fermented rice flour were also detected. The experimental results are as figure 1 As shown, the abscissa is the amount of sodium L-glutamate added (from left to right: 0, 0.5%, 1.0%, 1.5%, 2%), and the ordinate is the output of γ-aminobutyric acid in fermented rice flour ,from figure 1 It can be seen that when the amount of sodium L-glutamate is 1% or 2%, the yield of γ-aminobutyric acid in fermented rice flour can be further improved, especially when the amount of sodium L-glutamate is 1%. The highest yield of γ-aminobutyric acid was found in fermented rice flour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com