Collagen oligopeptide and extraction process thereof

A collagen extraction technology, applied in the direction of animal/human protein, specific peptide, connective tissue peptide, etc., can solve the problems of high molecular weight of collagen oligopeptide, insufficient collagen decomposition, low hydrolysis rate, etc., to achieve effective Facilitate digestion and absorption, reduce average molecular weight, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

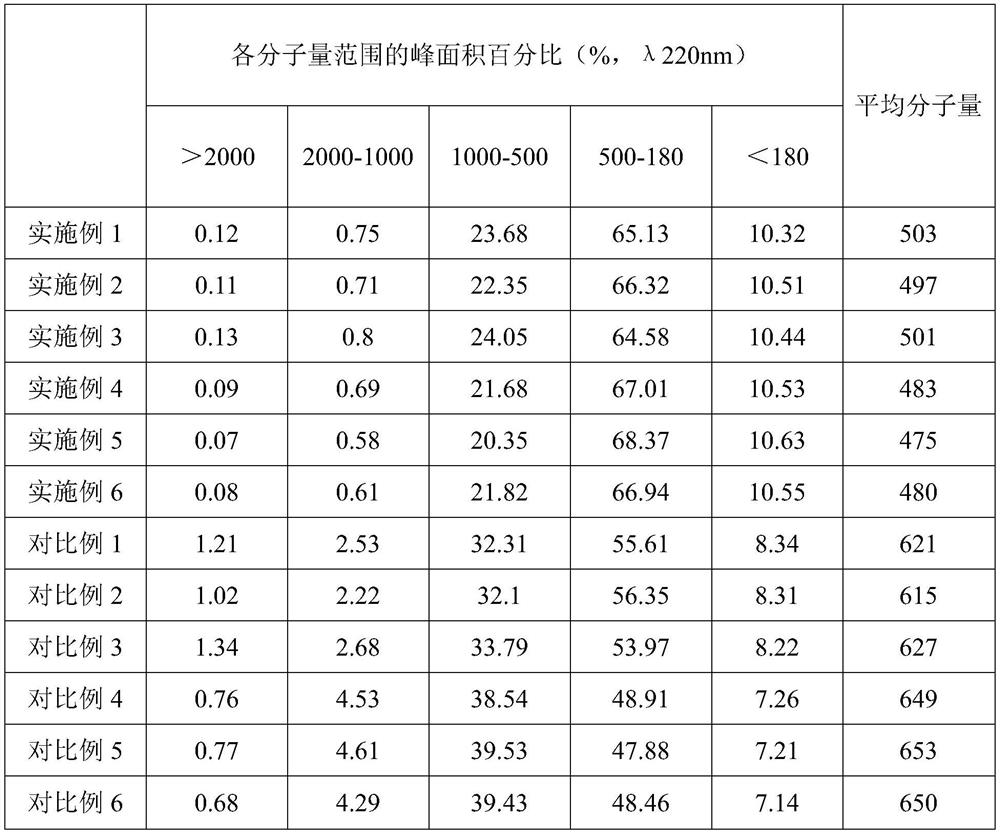

Examples

preparation example 1-3

[0039] A kind of adjusting solvent of preparation example 1-3, its each raw material and each raw material consumption are as shown in table 1, and its preparation method is as follows:

[0040] Each raw material is weighed according to the amount in Table 1, and then mixed evenly to adjust the solvent.

[0041] Each raw material and each raw material consumption (kg) of table 1 preparation example 1-3

[0042] Preparation Example 1 Preparation Example 2 Preparation Example 3 isopropyl alcohol 3 4 6 Ethanol 15 13 10 Diacetin 4 5 7

preparation example 4

[0044] A kind of adjusting solvent, the difference from Preparation Example 2 is that its raw material also includes 0.5kg of triethyl citrate, and the remaining steps are the same as those of Preparation Example 2.

preparation example 5

[0046] A kind of adjusting solvent, the difference from Preparation Example 2 is that its raw material also includes 1.0kg of triethyl citrate, and the remaining steps are the same as those of Preparation Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com