Preparation method of star-shaped alcohol amine ester polycarboxylic acid cement grinding aid

A technology of alcohol urethane polycarboxylic acid and cement grinding aid, which is applied in the field of materials, can solve the problems of decreased slurry fluidity and poor adaptability, and achieves the advantages of reduced production steps, good controllability, and mature production technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

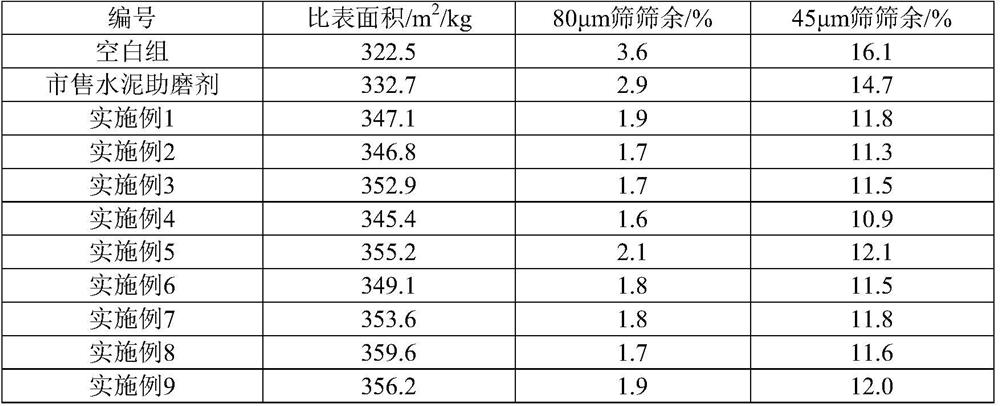

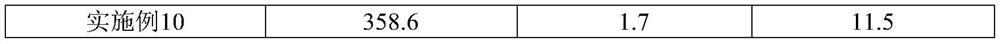

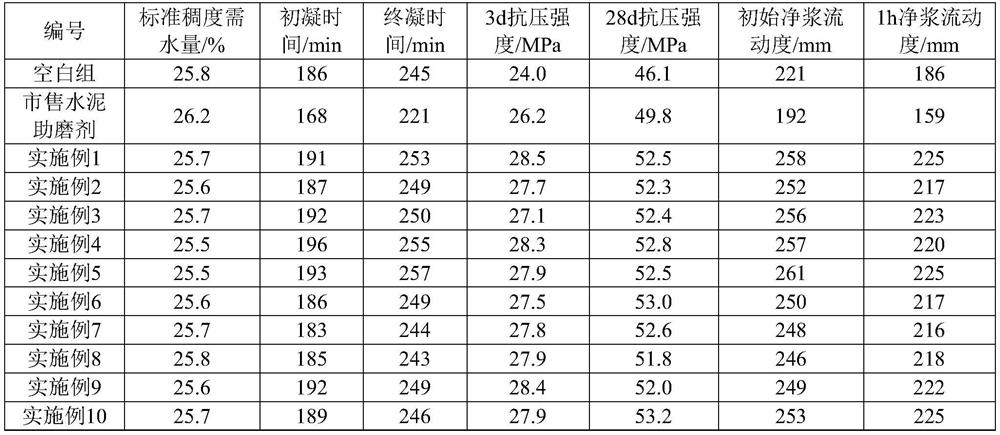

Examples

Embodiment 1

[0056] 1) 1mol triethanolamine, 3mol maleic acid, 1.2g hydroquinone, 1.3g p-hydroxyanisole are added to the reactor successively, under nitrogen protection, be warming up to 60 DEG C, stir 25 minutes, be warming up to 115 DEG C , add 4.97g of concentrated sulfuric acid and 49.7g of benzene, react for 3.5h, and separate the water generated by the reaction by vacuuming during the reaction. to room temperature to obtain unsaturated alcohol amine esterification product;

[0057] 2) 0.0055mol unsaturated alcohol amine esterification product, 0.045mol first part of acrylic acid, water are added in the reactor, be warming up to 70 DEG C, be down to room temperature after stirring 15 minutes, then add 0.05mol weight average molecular weight in the reactor 6000g / mol amino-terminated 4-hydroxybutyl vinyl polyoxyethylene polyoxypropylene ether, 0.0095mol ammonium persulfate, add water to adjust the concentration of the system to 50%, keep the reaction temperature at 25°C, and at the same...

Embodiment 2

[0059] 1) 1mol diethanol monoisopropanolamine, 0.3mol maleic acid, 3.7mol maleic anhydride, 18.0g 2-tert-butyl hydroquinone, 3.8g 2,6-dinitro-p-cresol are added to the reactor successively , under nitrogen protection, heat up to 70°C, stir for 30 minutes, heat up to 130°C, add 28g p-benzenesulfonic acid, 112g benzene, react for 10h, during the reaction, use vacuum method to separate the water generated by the reaction, wait for the multi-component After the hydroxyl groups in the alkanolamine are completely esterified, the water-carrying agent is removed by vacuuming, and it is lowered to room temperature to obtain an unsaturated alkanolamine esterified product;

[0060] 2) 0.0015mol unsaturated alcohol amine esterification product, 0.06mol first part of acrylic acid and methacrylic acid, water are added in the reactor, be warming up to 65 DEG C, be down to room temperature after stirring 25 minutes, then add 0.05% in the reactor. The mol weight-average molecular weight is 300...

Embodiment 3

[0062] 1) 1mol hydroxyethyl diisopropanolamine, 1mol maleic acid, 1mol fumaric acid, 1mol maleic anhydride, 0.5g hydroquinone, 2.0g 2-tert-butyl hydroquinone are added successively in the reactor , under nitrogen protection, heat up to 50°C, stir for 15 minutes, heat up to 100°C, add 5.0g concentrated sulfuric acid, 50g benzene, react for 12h, during the reaction, separate the water generated by the reaction by vacuuming, wait for the polyolamine After the middle hydroxyl groups are completely esterified, the water-carrying agent is removed by vacuuming, and then it is lowered to room temperature to obtain an unsaturated alcohol amine esterified product;

[0063] 2) 0.001mol unsaturated alcohol amine esterification product, 0.0225mol first part maleic acid, water are added in the reactor, be warming up to 60 ℃, be down to room temperature after stirring 15 minutes, then add 0.05mol heavyweight in the reactor. The average molecular weight is 3000g / mol amino-terminated isoprenol p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com