Polyester glass polymer, foam material and preparation method thereof

A foam material and polymer technology, which is applied in the fields of polyester glass polymer foam materials and polyester glass polymers, can solve the complex preparation of polyester vitrimers, the repeated processing performance of polyester polymers is reduced, and the Adverse effects of people and the environment, etc., to achieve the effect of unique self-healing properties, excellent thermal stability, and no performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In the present embodiment, the steps of preparing polyester glass polymer are as follows:

[0038] 100 parts by mass of polyethylene terephthalate (PET) pellets, 2-bis(2-hydroxyethyl)amino-2-hydroxymethyl-1,3-propanediol (BIS-TRIS) 0-0.8 The mass parts were melt-blended in an internal mixer for 1-3 minutes, and then 3 mass parts of pyromellitic dianhydride (PMDA) were added and melt-blended for 3.5 minutes. The torque had stabilized, and the samples were taken out to obtain polyester glass polymers. The temperature of the three zones of the internal mixer is controlled to be 270 °C, and the rotor speed is 60 rpm.

[0039] In this example, according to the different addition ratios of BIS-TRIS, 4 samples were prepared in total. The sample was named 0.3BT, the sample prepared when the amount of BIS-TRIS was 0.5 parts by mass was named 0.5BT, and the sample prepared when the amount of BIS-TRIS was 0.8 parts by mass was named 0.8BT.

Embodiment 2

[0041] In this example, the swelling ability of each sample prepared in Example 1 in trifluoroacetic acid, a good solvent, and the relaxation ability of the sample 0.8BT were tested.

[0042] 1. Swelling ability test

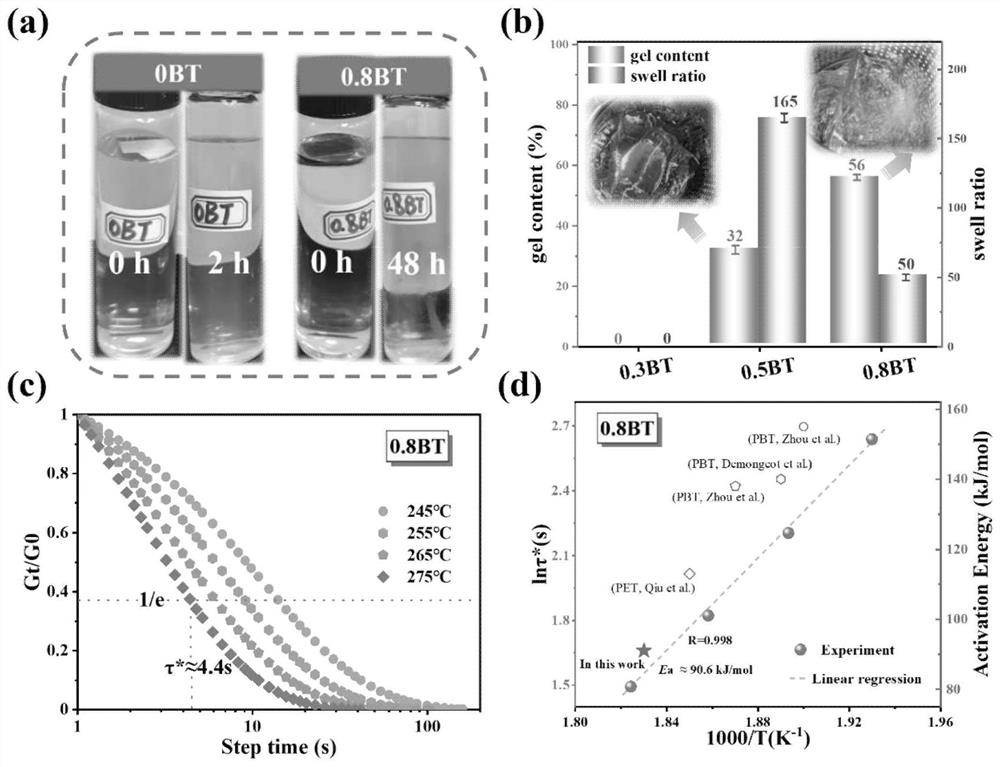

[0043] Immerse 0.5g of each sample (OBT, 0.3BT, 0.5BT and 0.8BT) in 40mL of trifluoroacetic acid, and place it at room temperature for 48h to observe the swelling. photos such as figure 1 (a) shown in Fig. Depend on figure 1 Figure (a) shows that the sample OBT was completely dissolved after being soaked in trifluoroacetic acid for 2 hours, indicating that no cross-linked network structure was formed, while the sample 0.8BT was still not dissolved after being soaked in trifluoroacetic acid for 48 hours, indicating that the formation of Cross-linked network structure.

[0044] Further test the gel content (gel content) and swelling ratio (swellratio) of each sample after soaking for 48h, the results are as follows figure 1 (b) shown in Fig. Depend on figur...

Embodiment 3

[0049] In this example, the rheological properties of each sample prepared in Example 1 were tested.

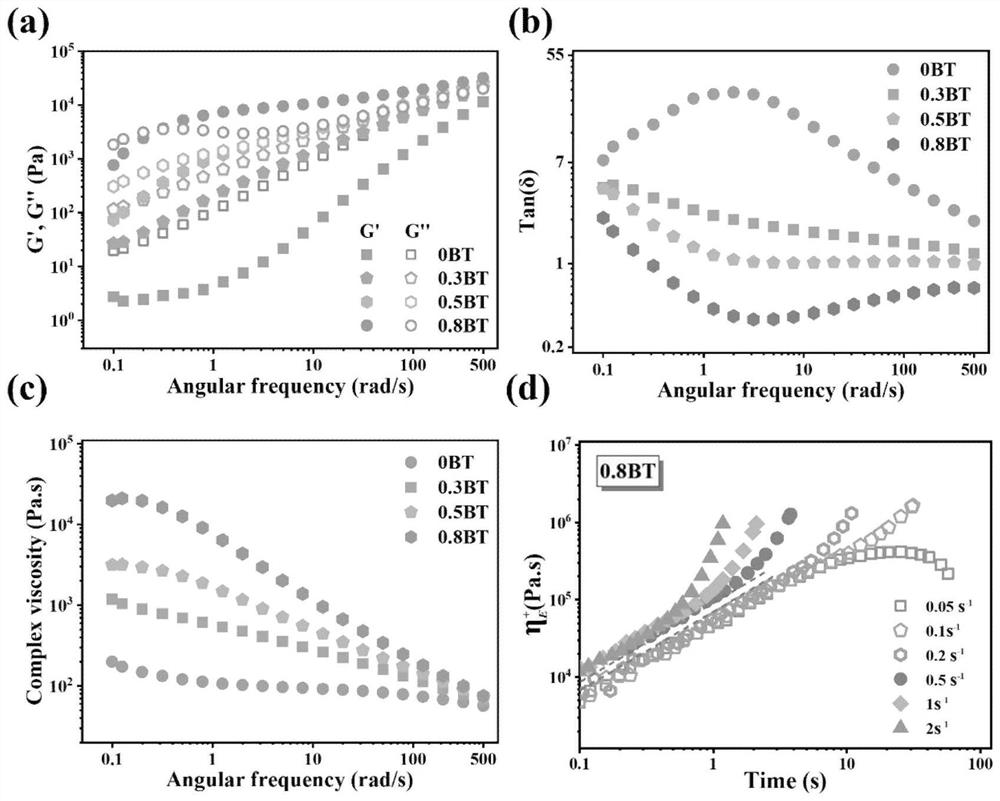

[0050] 1. Small-angle oscillating plate shear experiment

[0051] Each sample (OBT, 0.3BT, 0.5BT and 0.8BT) was placed on a flat vulcanizer and pressed at 270°C and 10MPa for 3min to obtain a disc sample with a diameter of 25mm and a thickness of 0.8mm. The small-angle oscillating plate shear experiments were performed on each wafer sample on a DHR-3 rheometer, that is, the storage modulus and loss mode of each sample were observed under the conditions of 270 °C, 1% strain, and 0.1-500 rad / s. quantity, complex viscosity, and loss tangent as a function of frequency. To avoid sample degradation, this experiment was performed at N 2 under protection. The result is as figure 2 (a) to (c) of Fig.

[0052] Depend on figure 2 Figures (a) to (c) show that the storage modulus of the sample gradually increases with the increase of the amount of BIS-TRIS added, indicating that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com