Photo-curable nano-zirconia dispersion liquid, preparation method thereof and optical film

A technology of nano-zirconia and dispersion liquid, applied in the direction of coating, etc., can solve the problems of low refractive index of dispersion liquid, ignoring hardness performance, low hardness of coating layer, etc., and achieve the effect of high process efficiency, high hardness and increased refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

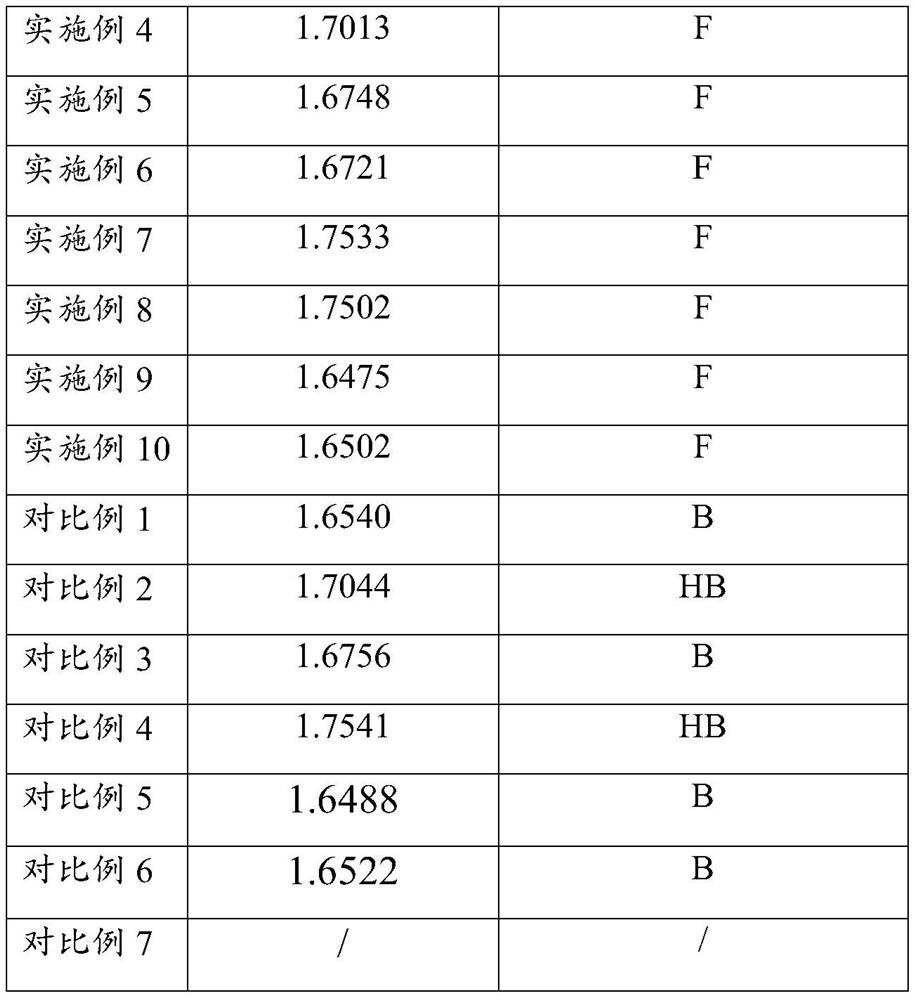

Examples

preparation example Construction

[0047] In the present invention, the preparation method of surface-modified zirconia comprises the following steps:

[0048] (A) providing the zirconia solution of the organic solvent phase;

[0049] Alternatively, the zirconia aqueous solution and the organic solvent can be concentrated and replaced to obtain a zirconia solution in the organic solvent phase;

[0050] Wherein, the zirconia mass concentration of the zirconia solution in the organic solvent phase is below 50%;

[0051] (B) adding the surface modifier to the zirconia solution of the above-mentioned organic solvent phase to modify the zirconia to obtain the modified mixed solution;

[0052] (C) the modified mixed solution obtained in step (B) removes the solvent to obtain surface-coated zirconia powder;

[0053] (D) The surface-coated zirconia powder obtained in step (C) is washed alternately with the first polar solvent and the second polar solvent, and then dried to obtain surface-modified zirconia;

[0054] ...

Embodiment 1

[0078] A preparation method of a photocurable nano-zirconia dispersion, comprising the following steps:

[0079] S1: take 400 g of a zirconia aqueous solution with a mass concentration of 20% (the particle size of zirconia is 5 nm), use a rotary evaporator to concentrate and remove water until the mass concentration of zirconia is above 30%, then add 240 g of propylene glycol methyl ether, and then concentrate Until the mass concentration of zirconia is more than 30%, repeat the procedure to replace water with propylene glycol methyl ether to obtain a zirconia solution with a mass concentration of 30% propylene glycol methyl ether phase;

[0080] S2: adding 6g isooctanoic acid and 6g silane KBM-503 to the zirconium oxide solution of the propylene glycol methyl ether phase obtained in step S1, and then refluxing and stirring at 120°C for 4 hours for surface modification to obtain a modified mixed solution;

[0081] S3: the modified mixed solution obtained in step S2 is subjecte...

Embodiment 2

[0085] The difference between this embodiment and Embodiment 1 is that the particle size of zirconia in this embodiment is 8 nm, and step S5 in this embodiment:

[0086] Weigh 30 g of purified surface-modified zirconia powder and surface-treated silicon oxide powder (the average particle size of silicon oxide is 3 nm, and the maximum particle size is less than 5 nm; the surface treatment method of silicon oxide is the same as in Example 1) 1.5g was dissolved in 150g butanone, and then 1.5g of BYK-111 dispersant was added to assist ultrasonic or grinding to fully dissolve and disperse the powder, and then 17g of o-phenylphenoxyethyl acrylate was added and evaporated under reduced pressure. After butanone, a zirconia dispersion liquid with a mass concentration of 60% is obtained, which is a photocurable nano-zirconia dispersion liquid;

[0087] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com