Core-shell type SAPO-34-coated ZSM-5 molecular sieve catalyst and preparation method thereof

A technology of SAPO-34 and ZSM-5, which is applied in the field of core-shell SAPO-34@ZSM-5 molecular sieve catalyst and its preparation, can solve problems such as two-phase separation, time consumption limitation, and reduction of zeolite crystallinity, and meet the conditions Relatively mild, increase the service life, the effect of easy raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

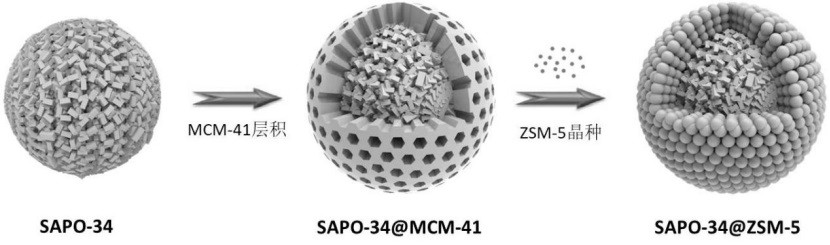

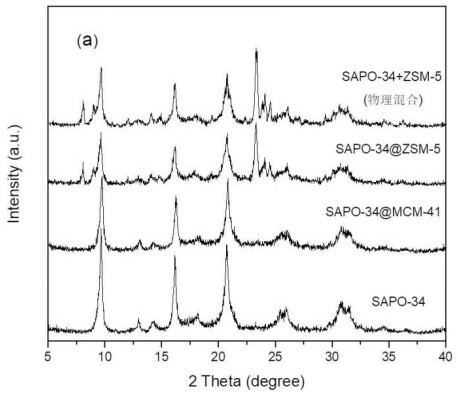

[0026] Example 1: Preparation of SAPO-34@ZSM-5

[0027] (1) Weigh 6.12g of aluminum isopropoxide and dissolve it in a solution of 30.3mL of distilled water and 35.3mL of tetrapropylammonium hydroxide, stir until completely dissolved, then add 3.6mL of ethyl orthosilicate and 4.0mL of phosphoric acid in sequence. After mixing evenly, it was transferred into a stainless steel reaction kettle with a volume of 100 mL, and hydrothermally crystallized at 180 °C for 3 days. The crystallized sample was washed to neutrality and dried at 80°C overnight to obtain solid powder;

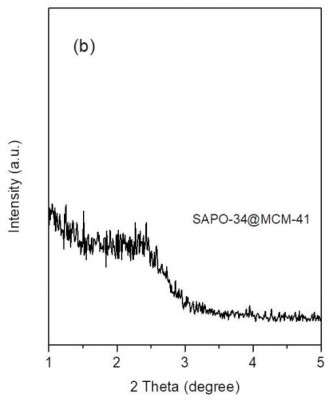

[0028] (2) 160g distilled water, 1.6g cetyltrimethylammonium bromide, 40mL isopropanol, 1mL ammonia water, 1.6ml ethyl orthosilicate and 2g SAPO-34 molecular sieve obtained in step (1) Put it into it, stir at 30 °C for 3 h, the final product was washed with distilled water, and dried at 80 °C overnight to obtain core-shell SAPO-34@MCM-41;

[0029](3) Weigh 10.98g of ethyl orthosilicate, 10.37g of tetrapropylamm...

Embodiment 2

[0032] For the preparation of SAPO-34@ZSM-5, in step (1), 7.01 g of ammonium dihydrogen phosphate was used, and the rest were the same as in Example 1.

Embodiment 3

[0034] For the preparation of SAPO-34@ZSM-5, in step (1), 4.23 g of ammonium monohydrogen phosphate was used, and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com