Process method for preparing lithium hydroxide from lithium phosphate

A technology of lithium hydroxide and process method, applied in lithium oxide;/hydroxide, chemical instrument and method, membrane technology and other directions, can solve the problem of high energy consumption of electrolysis method, achieve low recovery rate, low energy consumption, low purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

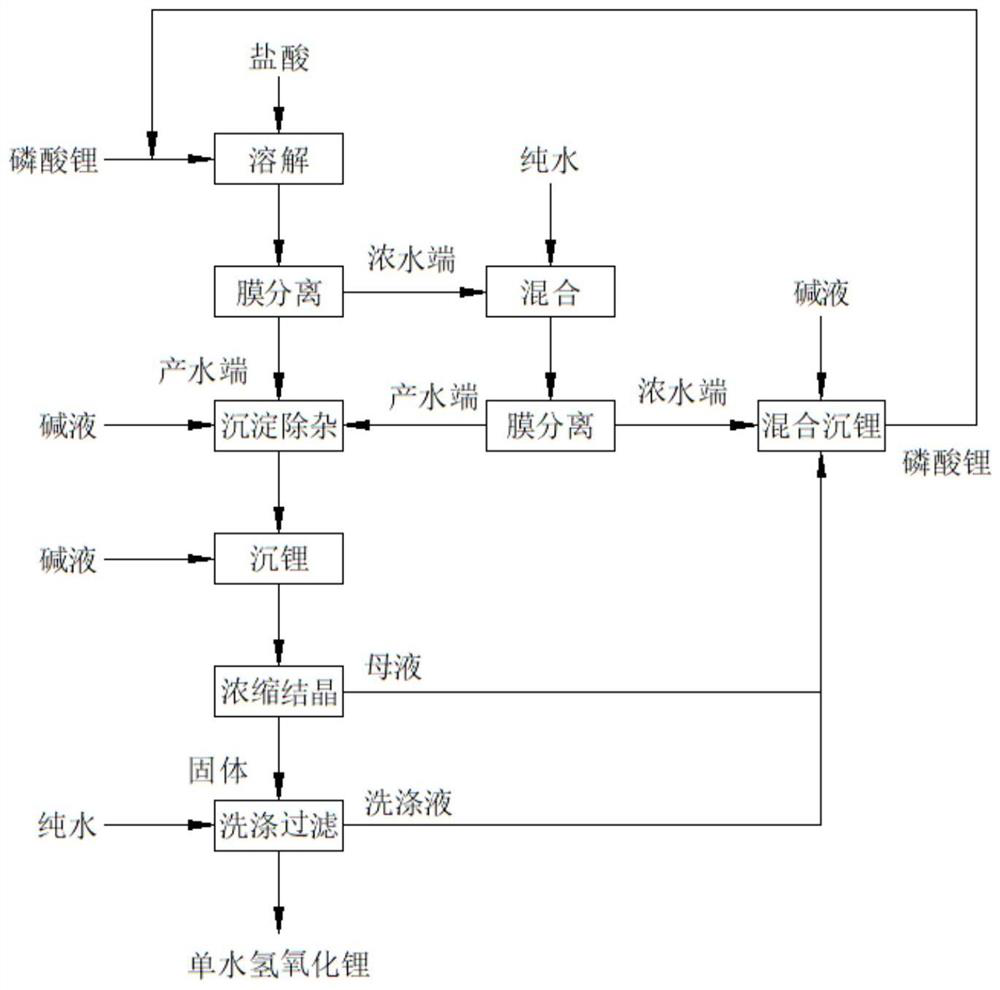

[0027] see figure 1 , the present embodiment provides a process method for preparing lithium hydroxide with lithium phosphate, comprising the following steps:

[0028] In step 1, the solid lithium phosphate is dissolved in a hydrochloric acid solution with a concentration of 40 g / L to obtain a mixed solution of lithium dihydrogen phosphate and lithium chloride; wherein, the molar ratio of the solid lithium phosphate to the content of hydrochloric acid in the hydrochloric acid solution is 1:2~ 1:3;

[0029] Li 3 PO 4 +2HCl=LiH 2 PO 4 +2LiCl

[0030] In step 2, a nanofiltration component (NF90 nanofiltration membrane) is used to separate the mixed solution obtained in step 1 for the first time, and the difference in molecular weight of lithium dihydrogen phosphate and lithium chloride is used to separate two lithium salts, and the water production rate is controlled at 45-65%, the water end of the nanofiltration module has a relatively pure lithium chloride solution;

[0...

Embodiment 2

[0041] see figure 1 , the present embodiment provides a process method for preparing lithium hydroxide with lithium phosphate, comprising the following steps:

[0042] In step 1, the solid lithium phosphate is dissolved in a hydrochloric acid solution with a concentration of 40 g / L to obtain a mixed solution of lithium dihydrogen phosphate and lithium chloride; wherein, the molar ratio of the solid lithium phosphate to the content of hydrochloric acid in the hydrochloric acid solution is 1:2~ 1:3;

[0043] Li 3 PO 4 +2HCl=LiH 2 PO 4 +2LiCl

[0044] In step 2, a nanofiltration component (NF90 nanofiltration membrane) is used to separate the mixed solution obtained in step 1 for the first time, and the difference in molecular weight of lithium dihydrogen phosphate and lithium chloride is used to separate two lithium salts, and the water production rate is controlled at 50-60%, the water product end of the nanofiltration component has a relatively pure lithium chloride solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com