Multi-process combined reinforced sludge carbon source recycling method

A sludge carbon and multi-process technology, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of biodegradability, complex structure of organic matter, and influence on denitrification rate, etc., to improve treatment Efficiency, high denitrification rate, total usage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

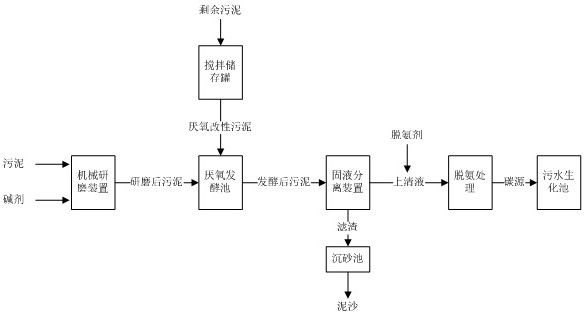

Method used

Image

Examples

Embodiment 1

[0026] The sludge used in this example is the sludge produced by the sewage treatment process of a sewage plant in Tianjin, with a moisture content of about 90%; the anaerobic modified sludge is the excess sludge produced by the anaerobic digestion tank of the cement plant, with a moisture content of about 98% .

[0027] The Ca(OH) 2 Powder mixed with sludge, Ca(OH) 2 The dosage is 0.9 g / L sludge, which is ground by a mechanical ball mill, the rotation speed is 10000r / min, and the grinding time is 50min.

[0028] The remaining activated sludge was added to the non-airtight stirred storage tank. The stirred storage tank was equipped with a stirrer. The culture temperature was 35 °C, the stirring rate was 60 r / min, and the sludge residence time was 2 d, and then part of the anaerobic modification was discharged. Sludge, and supplemented with new excess activated sludge, so the sludge is semi-continuously cultured to achieve anaerobic modification of sludge.

[0029] After the...

Embodiment 2

[0031] The sludge used in this example is the sludge produced by the sewage treatment process of a sewage plant in Tianjin, with a moisture content of about 90%; the anaerobic modified sludge is the excess sludge produced by the anaerobic digestion tank of the cement plant, with a moisture content of about 98% .

[0032] The Mg(OH) 2 Powder mixed with sludge, Mg(OH) 2 The dosage is 1.2 g / L sludge, which is ground by a wall breaker, the rotating speed is 30000r / min, and the grinding time is 20min.

[0033] The remaining activated sludge was added to the non-airtight stirred storage tank. The stirred storage tank was equipped with a stirrer. The culture temperature was 40 °C, the stirring rate was 70 r / min, and the sludge residence time was 1 d, and then part of the anaerobic modification was discharged. Sludge, and supplemented with new excess activated sludge, so the sludge is semi-continuously cultured to achieve anaerobic modification of sludge.

[0034] After the anaerob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com