Iron-carbon composite Fenton catalyst as well as preparation method and application thereof

A catalyst, iron-carbon technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of slow regeneration of Fenton reagent, insufficient mineralization of organic matter, insufficient utilization rate, etc., and achieve reduction Effects of pollution and harm, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

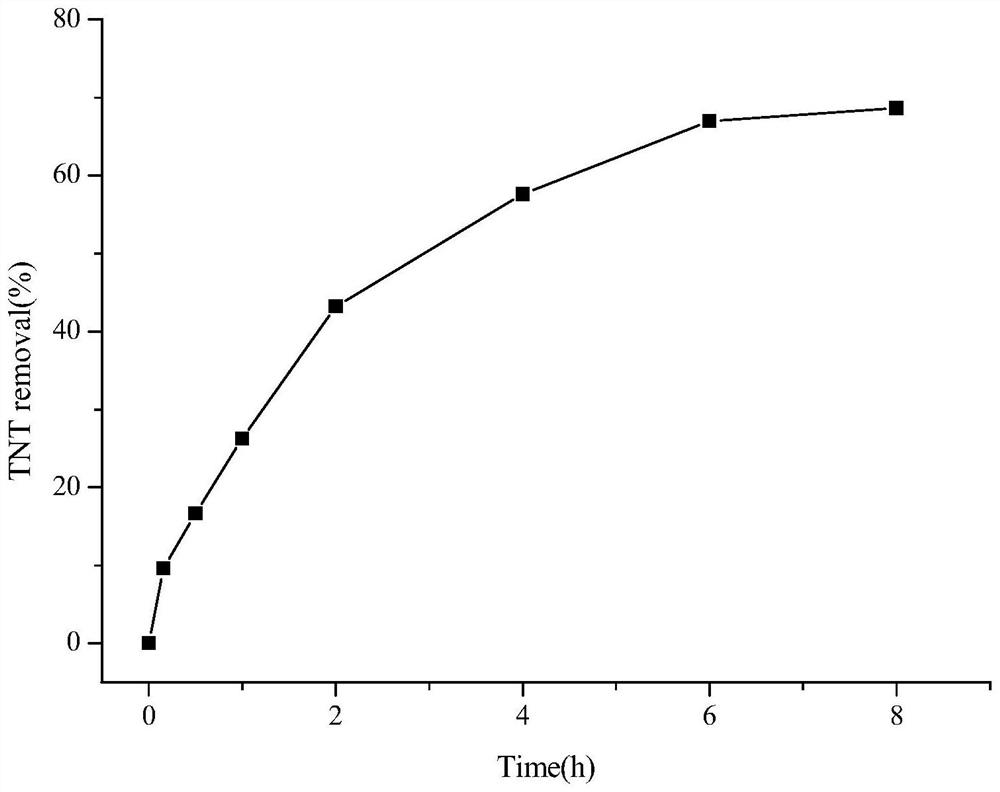

Embodiment 1

[0037] Collect a certain amount of kitchen waste, sort and remove impurities, remove impurities that cannot be carbonized, such as glass, metal, ceramics, etc., use a stirring and crusher to crush and homogenize, then drain the kitchen waste, weigh and drain After 100g of kitchen waste, add 100ml of deionized water to mix, add the mixture to a 500ml stainless steel reaction kettle, heat the mixture to 40°C, stir for 10min, and then ferric nitrate (Fe(NO) 3 ) 3 ) solution was added to the mixed solution (0.1mol / L), 5ml absolute ethanol was added dropwise as a dispersant, and stirring was continued for 5min; after the reactor was sealed, it was placed in a hydrothermal reaction device equipped with temperature control, electric heating and stirring Gradient heating was carried out, and the heating program was 170°C (1h), 200°C (3h), 230°C (5h) and 260°C (10h), while stirring (100r / min), the heating rate was kept at 3°C / min; the reaction was over Then, the reaction kettle was co...

Embodiment 2

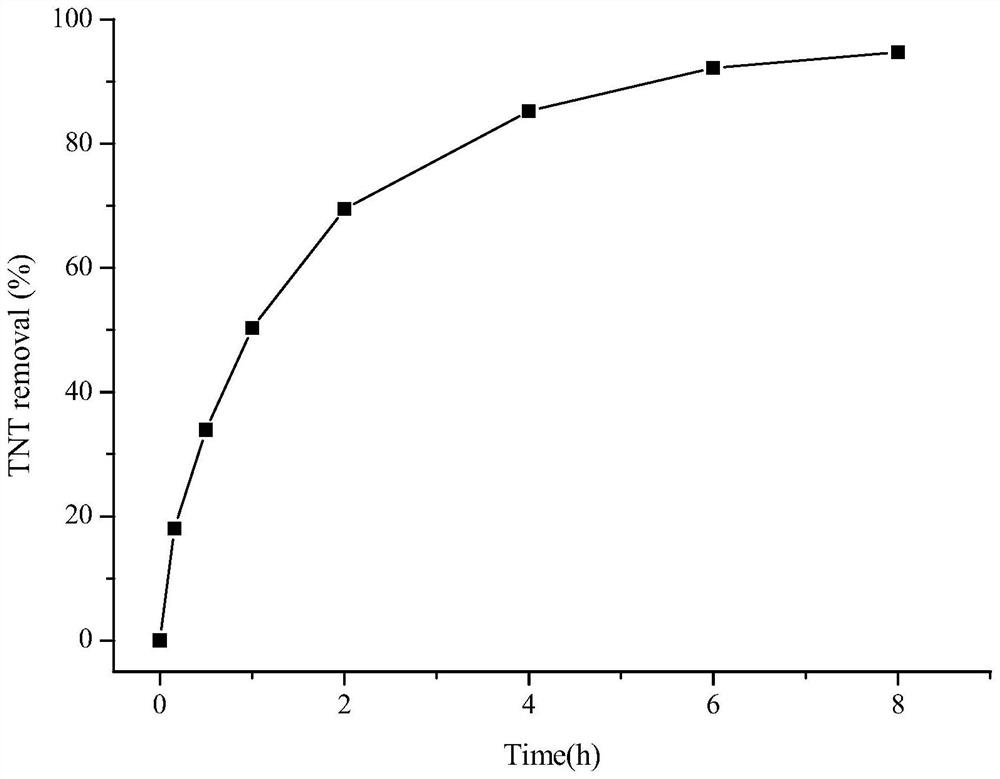

[0039]Collect a certain amount of kitchen waste, sort and remove impurities, remove impurities that cannot be carbonized, such as glass, metal, ceramics, etc., use a stirring and crusher to crush and homogenize, then drain the kitchen waste, weigh and drain After 150g of kitchen waste, add 150ml of deionized water to mix, add the mixture to a 500ml stainless steel reaction kettle, heat the mixture to 45°C, stir for 20min, and add ferric chloride (FeCl 3 ) solution was added to the mixed solution (0.3mol / L), 7.5ml of absolute ethanol was added dropwise as a dispersant, and the stirring was continued for 8min; after the reactor was sealed, it was placed in a hydrothermal reaction device equipped with temperature control, electric heating and stirring Gradient heating was carried out during the heating process, and the heating program was 180°C (1h), 210°C (3h), 240°C (5h) and 270°C (10h), while stirring (150r / min), the heating rate was maintained at 4°C / min; the reaction After t...

Embodiment 3

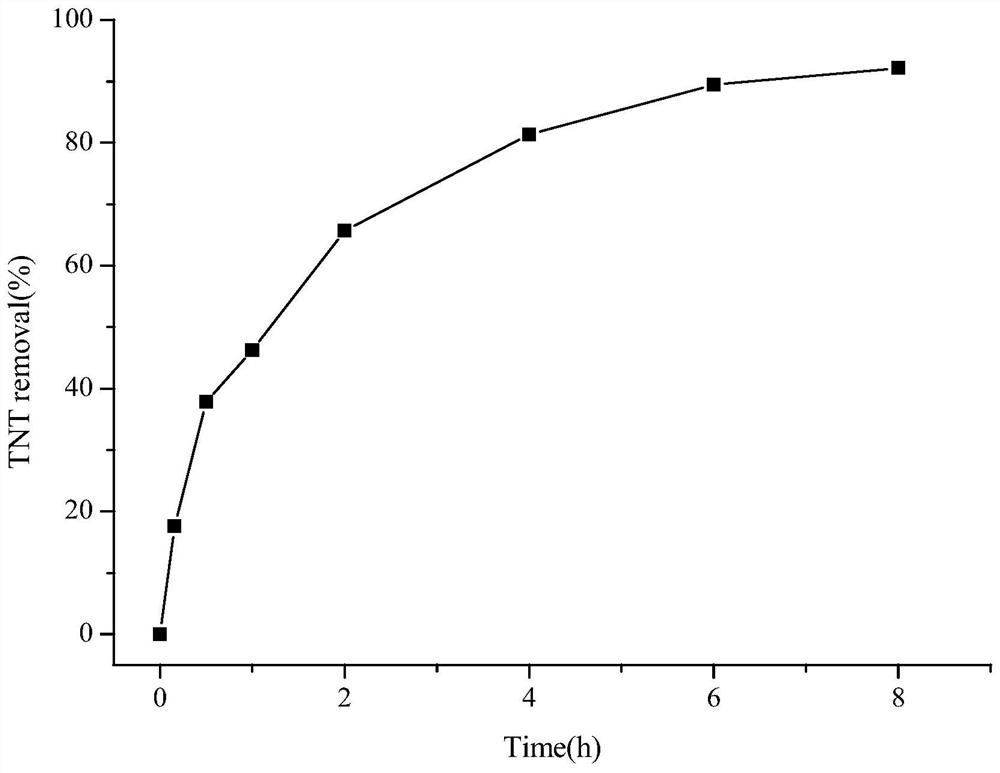

[0041] Collect a certain amount of kitchen waste, sort and remove impurities, remove impurities that cannot be carbonized, such as glass, metal, ceramics, etc., use a stirring and crusher to crush and homogenize, then drain the kitchen waste, weigh and drain After 200g of kitchen waste, add 200ml of deionized water to mix, add the mixture to a 500ml stainless steel reaction kettle, heat the mixture to 50°C, stir for 30min, and then add iron sulfide (FeSO4). 4 ) solution was added to the mixed solution (0.5mol / L), 10ml of absolute ethanol was added dropwise as a dispersant, and the stirring was continued for 10min; after the reactor was sealed, it was placed in a hydrothermal reaction device equipped with temperature control, electric heating and stirring Gradient heating was carried out, and the heating program was 190°C (1h), 220°C (3h), 250°C (5h) and 280°C (10h), while stirring (200r / min), the heating rate was kept at 5°C / min; the reaction was over After that, the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com