Preparation method and application of tert-butyl acetylene

A tert-butylacetylene and reaction technology, which is applied in the preparation of amino-substituted functional groups, hydrocarbon production from halogen-containing organic compounds, organic chemistry, etc., can solve the problems of high price of bromobutyllithium, increased raw material cost, and reduced product purity, etc. To achieve the effect of providing purity, easier recovery, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

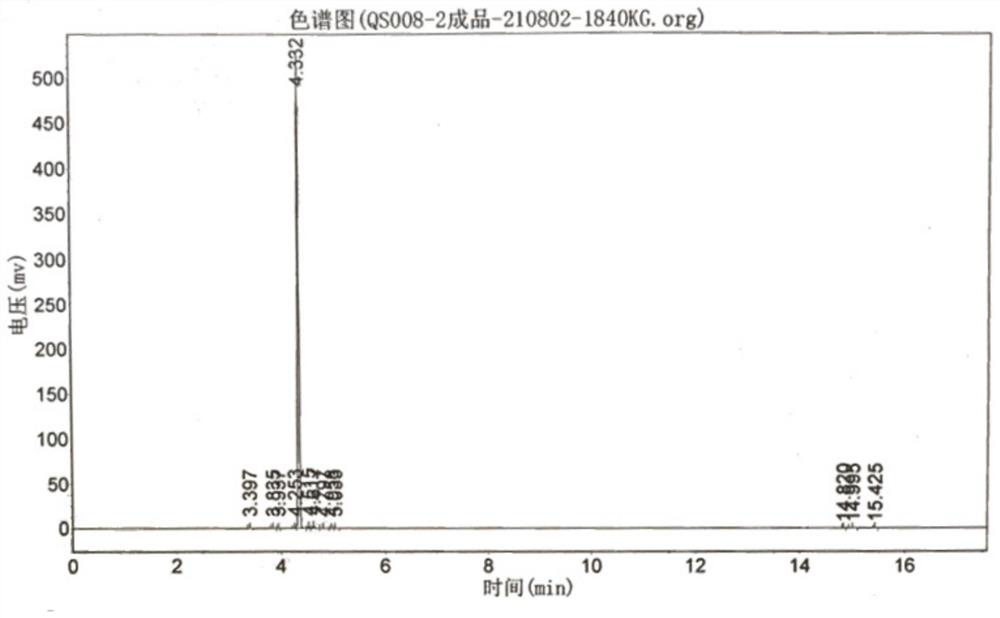

Image

Examples

Embodiment 1

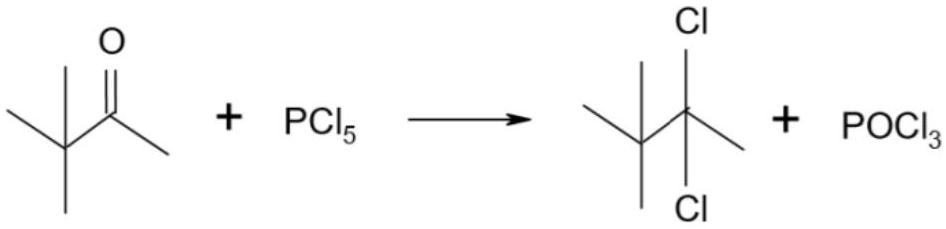

[0045] The preparation method of a kind of tert-butylacetylene provided by this embodiment, comprises the following steps:

[0046] (1) add 400 kilograms of xylenes in the reactor, add 390 kilograms of phosphorus pentachloride in stages, stir to make it fully dissolved; 195 kilograms of pinacolone are added dropwise at 10 ° C, and the dropwise addition is completed in about 8 hours, and the reaction generates 2 ,2-dichloro-3,3-dimethylbutane;

[0047] After the completion of the reaction, add ice-water mixture to the reactor, stand for stratification; separate the organic layer, extract 270 kilograms of 2,2-dichloro-3,3-dimethylbutane, 2,2-dichloromethane The yield of -3,3-dimethylbutane was 93.1%;

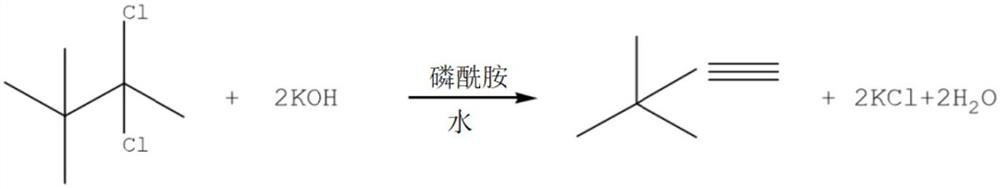

[0048] (2) in dechlorination still, add 405 kilograms of potassium hydroxide, 180 kilograms of phosphoramide, 270 kilograms of 2,2-dichloro-3,3-dimethylbutane and 1000 kilograms of water, be warming up to 180 ℃ of reaction, and Control the reaction temperature not to exceed 250 ...

Embodiment 2

[0057] The preparation method of a kind of tert-butylacetylene provided by this embodiment, comprises the following steps:

[0058] (1) add 200 kilograms of xylenes in the reactor, add 180 kilograms of phosphorus pentachloride in stages, stir and make it fully dissolved; 180 kilograms of pinacolone are added dropwise at 30 ° C, and the dropwise addition is completed in about 7.5 hours, and the reaction generates 2 ,2-dichloro-3,3-dimethylbutane;

[0059] After the completion of the reaction, add ice-water mixture to the reactor, stand for stratification; separate the organic layer, extract 120 kilograms of 2,2-dichloro-3,3-dimethylbutane, 2,2-dichlorobutane The yield of -3,3-dimethylbutane was 89.6%;

[0060] (2) in dechlorination still, add 360 kilograms of sodium hydroxide, 100 kilograms of phosphoramide, 120 kilograms of 2,2-dichloro-3,3-dimethylbutane and 800 kilograms of water, be warming up to 180 DEG C of reaction, and Control the reaction temperature not to exceed 25...

Embodiment 3

[0068] The preparation method of a kind of tert-butylacetylene provided by this embodiment, comprises the following steps:

[0069] (1) in reactor, add 400 kilograms of xylene, add 130 kilograms of phosphorus pentachloride in stages, stir to make it fully dissolved; 300 kilograms of pinacolone are added dropwise at 25 ° C, and the dropwise addition is completed in about 13 hours, and the reaction generates 2 ,2-dichloro-3,3-dimethylbutane;

[0070] After the reaction is completed, add ice-water mixture to the reaction kettle, let stand for stratification; separate the organic layer, extract 92 kilograms of 2,2-dichloro-3,3-dimethylbutane, 2,2-dichlorobutane -3,3-dimethylbutane in 95% yield;

[0071] (2) in the dechlorination still, add 184 kilograms of sodium hydroxide, 70 kilograms of phosphoramide, 92 kilograms of 2,2-dichloro-3,3-dimethylbutane and 500 kilograms of water, be warming up to 180 ℃ of reaction, and Control the reaction temperature not to exceed 250 ℃, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com