Organic/inorganic hybrid modified graphene waterborne epoxy micaceous iron oxide intermediate paint as well as preparation method and application thereof

A technology of epoxy cloud iron and water-based epoxy emulsion, which is applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of difficult graphene dispersion, improve shielding performance, good dispersion, and improve anti-sedimentation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

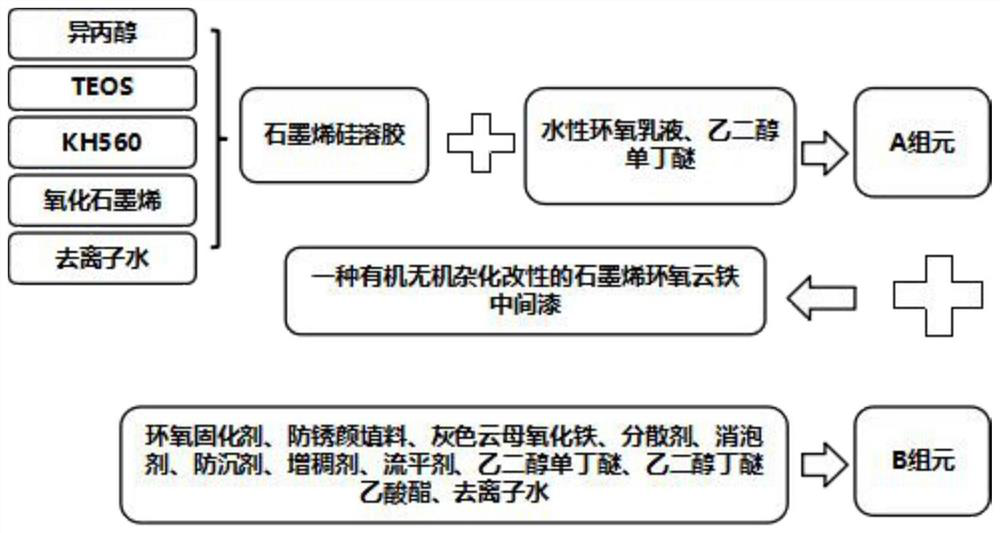

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Preparation of organic-inorganic hybrid modified graphene water-based epoxy micaceous iron intermediate paint

[0046] The first step: preparation of organic-inorganic hybrid graphene silica sol

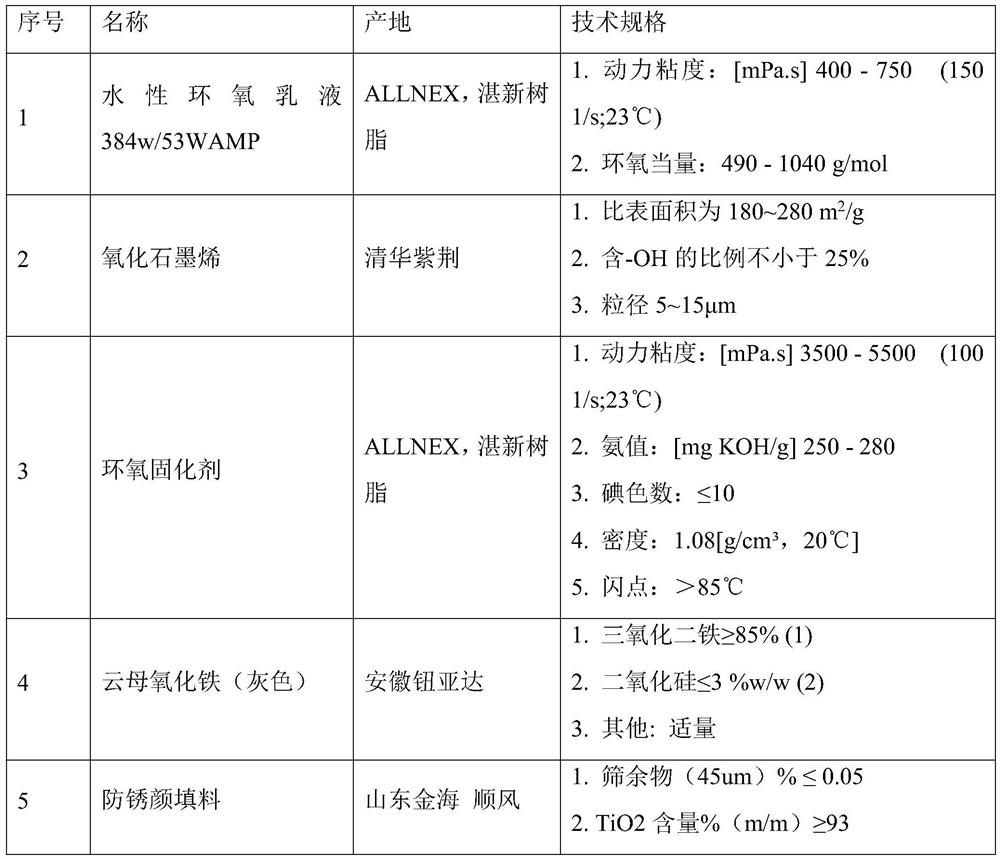

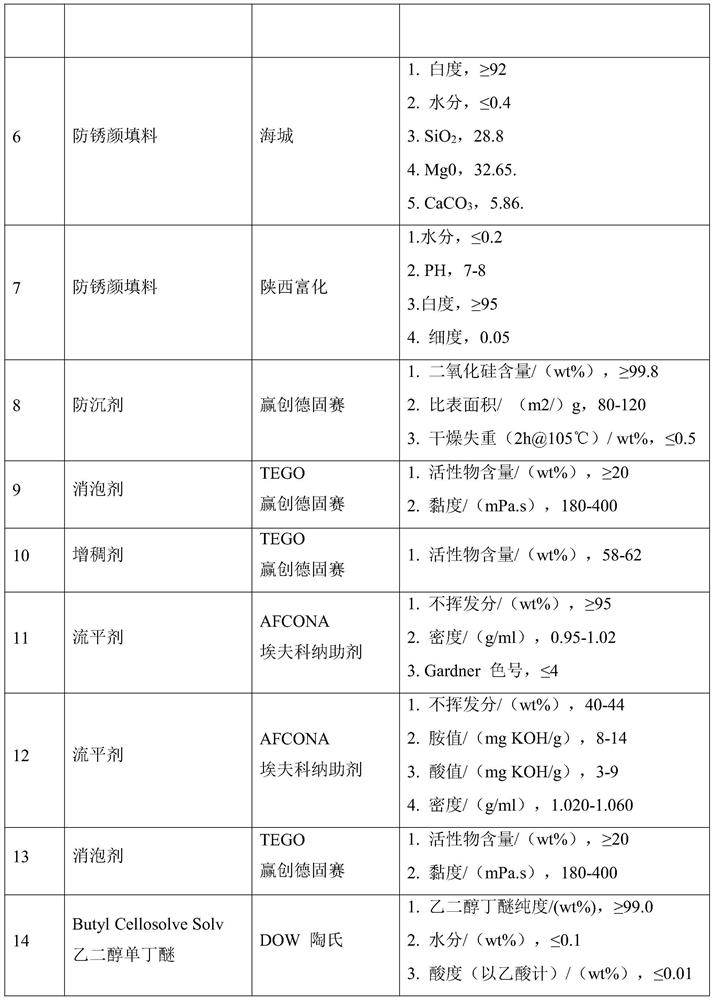

[0047] X component includes: isopropanol (8mL) + tetraethyl orthosilicate TEOS (10mL) + silane coupling agent KH-560 (10mL) + graphene oxide (0.5mg);

[0048] Y component included: deionized water (1 mL) + isopropanol (7 mL).

[0049] (1) Set the specific surface area to 100-200m 2 / g, the proportion of -OH is less than 5%, 0.5 mg of graphene oxide with a particle size of 0.5 to 5 μm is added to 10 ml of silane coupling agent KH560, and the silane-modified graphene dispersion is prepared by circulating ultrasonic dispersion for 30 minutes;

[0050] (2) 8mL of isopropanol and 10mL of LTEOS were added to the silane-modified graphene dispersion, stirred at room temperature for 3-5min to make it evenly mixed, and NaOH was added to adjust the pH of the solution to pH9-...

Embodiment 2

[0067] Example 2: Preparation of organic-inorganic hybrid modified graphene water-based epoxy micaceous iron intermediate paint

[0068] The first step: preparation of organic-inorganic hybrid graphene silica sol

[0069] X component includes: isopropanol (8mL) + tetraethyl orthosilicate TEOS (10mL) + silane coupling agent KH-560 (10mL) + graphene oxide (0.5mg);

[0070] Y component includes: deionized water (1mL) + isopropanol (7mL)

[0071] (1) Set the specific surface area to 100-200m 2 / g, the proportion of -OH is less than 5%, 0.5 mg of graphene oxide with a particle size of 0.5 to 5 μm is added to 10 ml of silane coupling agent KH560, and the silane-modified graphene dispersion is prepared by circulating ultrasonic dispersion for 30 minutes;

[0072] (2) 8mL of isopropanol and 10mL of TEOS are added to the silane-modified graphene dispersion, stirred at room temperature for 3-5min to make it evenly mixed, and NaOH is added to adjust the pH of the solution to pH9-10 to ...

Embodiment 3

[0090] Example 3: Preparation of organic-inorganic hybrid modified graphene water-based epoxy micaceous iron intermediate paint

[0091] The first step: preparation of organic-inorganic hybrid graphene silica sol

[0092] X component includes: isopropanol (8mL) + tetraethyl orthosilicate TEOS (10mL) + silane coupling agent KH-560 (10mL) + graphene oxide (0.5mg);

[0093] Y component includes: deionized water (1mL) + isopropanol (7mL)

[0094] (1) Set the specific surface area to 100-200m 2 / g, the proportion of -OH is less than 5%, 0.5 mg of graphene oxide with a particle size of 0.5 to 5 μm is added to 10 ml of silane coupling agent KH560, and the silane-modified graphene dispersion is prepared by circulating ultrasonic dispersion for 30 minutes;

[0095] (2) 8mL of isopropanol and 10mL of LTEOS were added to the silane-modified graphene dispersion, stirred at room temperature for 3-5min to make it evenly mixed, and NaOH was added to adjust the pH of the solution to pH9-10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com