Compound microbial agent for promoting nitrogen utilization of crops as well as preparation method and application of compound microbial agent

A compound microbial agent and crop technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, botany equipment and methods, etc., can solve the problems of lack of diversity of functions, single strain, low transformation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

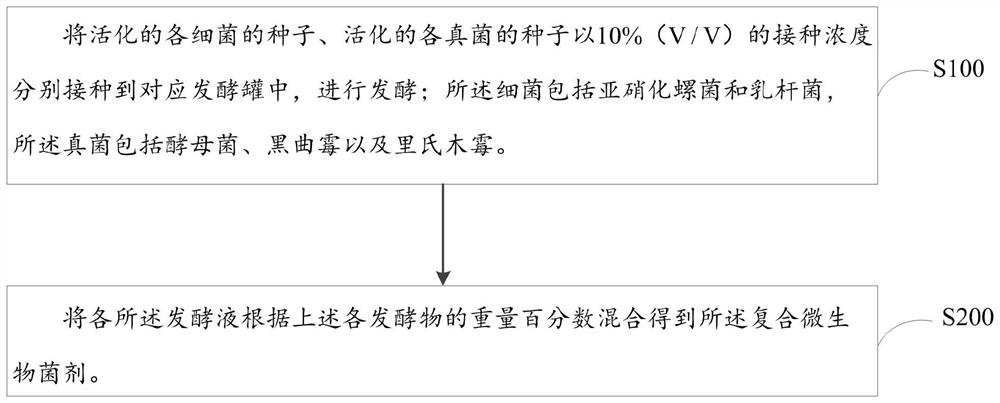

[0035] In a second aspect of the present application, a method for preparing a composite microbial inoculum is provided. The above-mentioned composite microbial inoculum can be prepared by fermenting each bacterium and each fungus separately, and then mixing the fermented liquid. In some of these embodiments, see figure 1 , the preparation method comprises the following steps:

[0036] S100: the seeds of each activated bacteria and the seeds of each activated fungi are respectively inoculated into corresponding fermenters at an inoculation concentration of 10% (V / V), and fermented; the bacteria include N. eutropha and Lactobacillus, The fungi include yeast, Aspergillus niger, and Trichoderma reesei.

[0037] S200: Mix the fermentation broths according to the weight percentages of the fermentation products to obtain the composite microbial inoculum.

[0038] In this case, the corresponding fermentation broths are obtained by culturing N. eutropha and Lactobacillus, yeast, As...

Embodiment 1

[0063] Nitrosospira, Lactobacillus, yeast, Aspergillus niger, and Trichoderma reesei were inoculated into the first medium, respectively, and cultured in a shaker (120 rpm, 35° C.) for activation. The first medium includes: glucose 0.3g / L, yeast extract powder 0.2g / L, KH 2 PO 4 0.01g / L, MgSO 4 0.01 g / L, the pH of the first culture medium is 5.5-6.0.

[0064] The seeds of the activated bacteria and the activated fungi were respectively inoculated into the corresponding fermenters for pure culture in the first medium, and the inoculation amount was 10% (V / V). Under the condition of 35°C, the aeration rate was adjusted to 1.0vvm (gas volume / liquid volume / min), the stirring rate was 50-150rpm, and the dissolved oxygen (DO) concentration was maintained at about 60-100% for fermentation.

[0065] After 24h of fermentation, the high-concentration sterile glucose solution (50%) is sent into the fermenter through the peristaltic pump for feeding, and the glucose concentration in the...

Embodiment 2

[0069] The difference from Example 1 is that the composite microbial inoculum comprises the following components by mass percentage: 30% of Nitrospirulina fermented product, 20% of Lactobacillus fermented product, 20% of yeast fermented product, Aspergillus niger Fermentation 20% and Trichoderma reesei Fermentation 20%. The rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com