High-density fermentation method of recombinant EK enzyme engineering bacteria

A technology of high-density fermentation and enzyme engineering, applied in the field of high-density fermentation of recombinant EK enzyme engineering bacteria, can solve the problems of low expression efficiency of construction engineering bacteria, high cost of enzyme production, and difficulty in improving product yield, etc. The effect of application value, cost reduction, and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] This example is used to illustrate the construction process of recombinant EK enzyme engineering bacteria:

[0094] 1. Synthesis of recombinant bovine enterokinase light chain expression cassette

[0095] Synthesize expression cassettes for expressing the recombinant fusion protein of the present invention, and the expression cassettes respectively express the EK of the present invention L m1 and EK L Recombinant fusion protein of m3 expressing EK L The expression cassette sequence of m1 is shown in SEQ ID No. 3, expressing EK L The expression cassette sequence of m3 is shown in SEQ ID No.4.

[0096] 2. Construction of expression vector of recombinant protein and construction of engineering bacteria

[0097] The expression EK constructed in step 1 above was L m1 and EK L The m3 expression cassette sequence was inserted into the expression vector pET-30a(+) NdeI and Xho The recombinant expression vector was constructed and obtained between the I restriction site...

Embodiment 2

[0140] Adopt the recombinant EK enzyme engineering bacteria constructed in Example 1 to carry out high-density culture:

[0141] 1. Strain activation:

[0142] First-level activation: In the ultra-clean workbench, take 50 μL of frozen glycerol bacteria into a 250-mL conical flask containing 50 mL of activation medium and cultivate in a constant temperature shaker at a temperature of 37.0 ± 1.0 °C and a rotation speed of 220 ± 10 rpm , the incubation time is 12 to 16 hours.

[0143] Two-stage activation: In the ultra-clean workbench, take 40 mL of the above-mentioned first-stage activated seed culture solution and put it into a 1000-mL conical flask containing 200 mL of activation medium and cultivate in a constant temperature shaker at a temperature of 37.0±1.0 °C and a rotation speed of 220 ±10 rpm, incubation time 3 hours.

[0144] 2. Fermentation regulation:

[0145] (1) Initial parameter setting of fermentation tank

[0146] Temperature: 37.0±1.0°C, air flow: 500mL / min...

Embodiment 3

[0158] Based on the method of Example 2, the difference is:

[0159] (1) Reduce the concentration of yeast extract powder in the feed medium;

[0160] (2) The induction OD600 value was adjusted from 160 to 150, and the growth rate of the bacteria before induction was reduced (the OD600 value reached 150 after 12-14 hours of feeding);

[0161] (3) The feed medium adopts formula 2; other conditions are the same as those of embodiment 2.

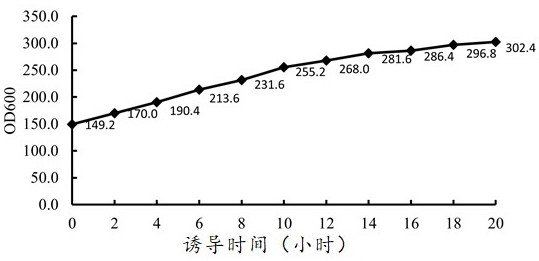

[0162] Fermentation results: Growth curves such as image 3 As shown, the bacterial collection data and HPLC expression detection results are shown in Table 8:

[0163] Table 8

[0164]

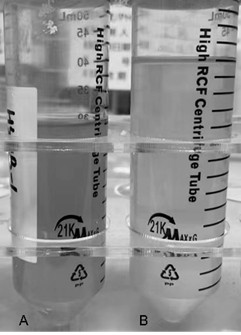

[0165] The contrast photos of the inclusion body pigments expressed in Example 2 and Example 3 are as follows: Figure 4 shown. Wherein A is the color and luster of the expression product of Example 2 after dissolution, and B is the color and luster of the expression product of Example 3 after dissolution.

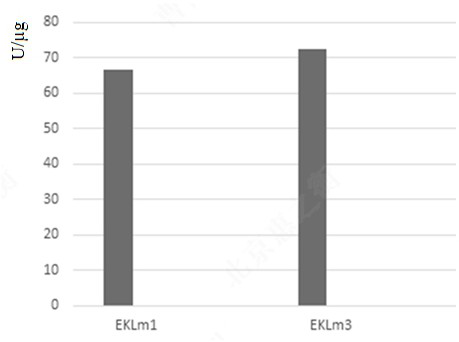

[0166] According to the experimental data o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com