Waste glass fiber reinforced plastic fiber reinforced solidified sludge block and preparation method thereof

A technology for solidifying silt and fiber reinforcement, applied in the field of silt solidification, can solve the problems of easy cracking toughness, insufficient compressive strength, etc., and achieve the effect of improving overall performance, reducing production cost and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

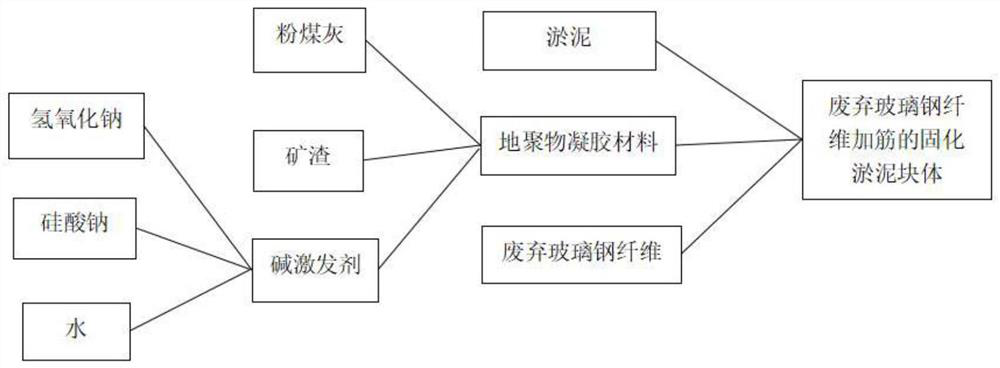

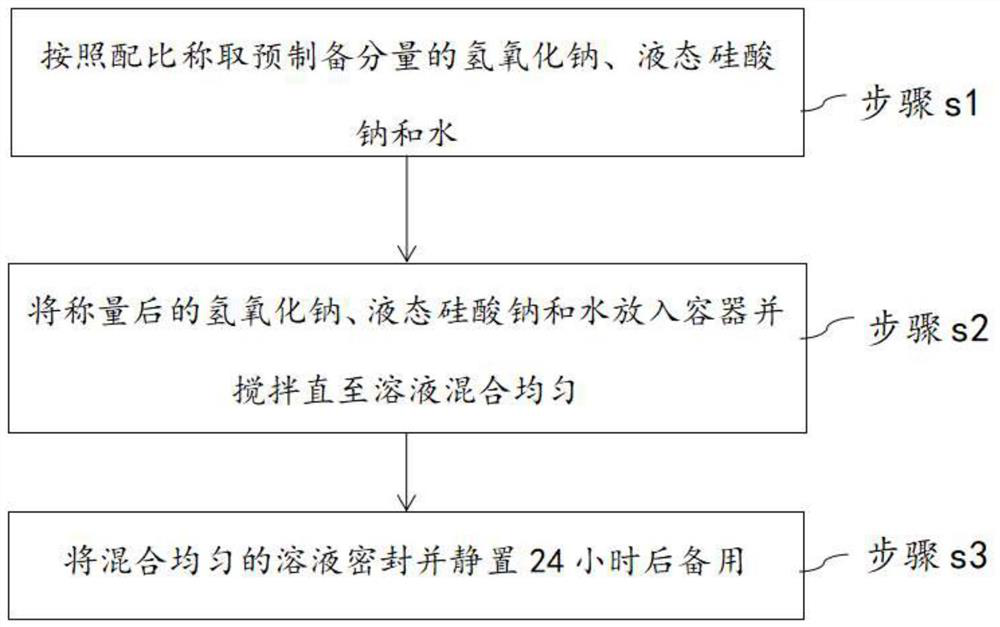

[0054] see figure 2 As shown, it is a flow chart of the preparation method of the alkali activator of the present invention, and the preparation method of the alkali activator comprises:

[0055] Step s1, take by weighing the sodium hydroxide, liquid sodium silicate and water of the pre-prepared components according to the proportioning;

[0056] Step s2, put the weighed sodium hydroxide, liquid sodium silicate and water into a container and stir until the solution is evenly mixed;

[0057] In step S3, the homogeneously mixed solution is sealed and left for 24 hours before use.

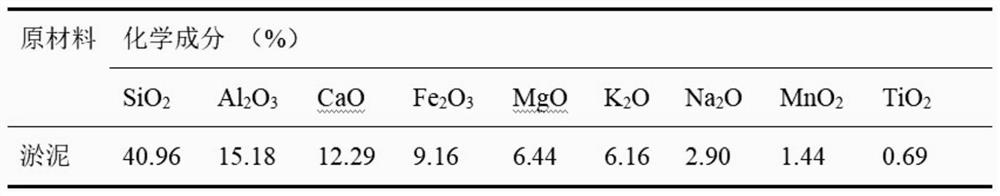

[0058] see image 3 As shown, it is the chemical composition and content table of the silt of the present invention, and the composition structure in the described silt is mainly quartz, kaolinite, illite and muscovite, please refer to Figure 4 , Figure 5 As shown, the initial moisture content of the sludge is 80%-120%, the liquid limit and plastic limit are 81% and 39%, the plasticity index is...

specific Embodiment 1

[0074] The invention provides a solidified sludge block reinforced by waste glass fiber reinforced plastics, which is prepared according to the material of solidifying 1 ton of sludge. , Fly ash 75kg, slag 75kg, water 40kg, sodium hydroxide 9.6kg, sodium silicate 6.4kg. The solid sodium hydroxide, liquid sodium silicate and water were poured into a glass beaker, stirred clockwise with a glass rod until the solution was evenly mixed, and then the mixed solution was sealed with a plastic film and allowed to stand for 24 hours before use.

[0075]Specifically, the mechanical properties of the solidified sludge block prepared according to the proportioning in Example 1 were tested, and the residual strength value of the block in the 28d double peak strain environment was 815kPa, and the 7d unconfined compressive strength was 301kPa, 28d unconfined compressive strength is 1245kPa, 7d indirect tensile strength is 89.46kPa, 28d indirect tensile strength is 196.45kPa, CBR value is 16....

specific Embodiment example 2

[0077] The invention provides a solidified sludge block reinforced by waste glass fiber reinforced plastics, which is prepared according to the material of solidifying 1 ton of sludge. , 75kg of fly ash, 75kg of slag, 40kg of water, 9.6kg of sodium hydroxide, 6.4kg of sodium silicate, and 1kg of waste FRP fiber. The solid sodium hydroxide, liquid sodium silicate and water were poured into a glass beaker, stirred clockwise with a glass rod until the solution was evenly mixed, and then the mixed solution was sealed with a plastic film and allowed to stand for 24 hours before use.

[0078] Specifically, the mechanical properties of the solidified silt blocks reinforced with waste FRP fibers prepared according to the proportions in Example 2 were tested, and the residual strength value of the block under the twice peak strain environment of 28d was 623kPa, and no value of 7d was obtained. The confining compressive strength is 398kPa, the 28d unconfined compressive strength is 1299...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com