Preparation method of brominated butyl rubber under action of phase transfer agent

A technology of brominated butyl rubber and phase transfer agent, which is applied in the field of butyl rubber, can solve the problem of low utilization rate of bromine element, and achieve the effect of increasing bromination reaction speed and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

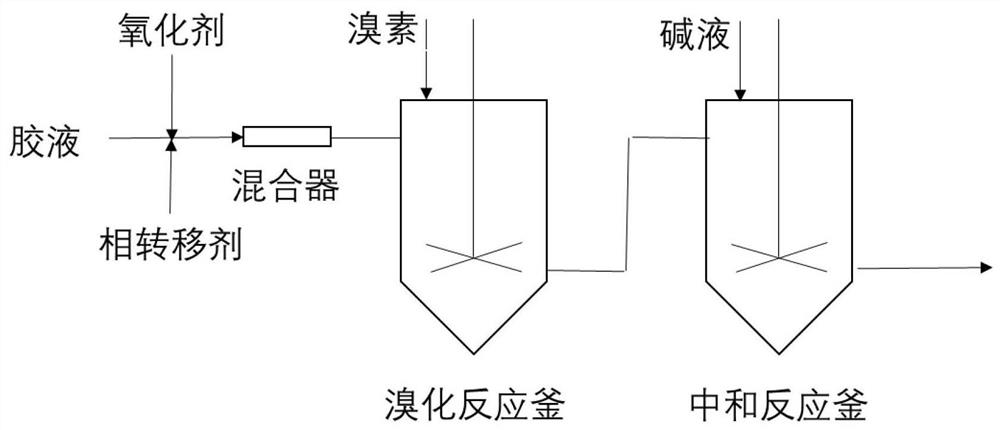

[0026] In the present invention, the preparation method of bromobutyl rubber under the action of the phase transfer agent specifically comprises the following steps:

[0027] Mix the butyl rubber solution, the oxidant and the phase transfer agent to obtain a mixed glue; wherein the mass ratio of the butyl rubber to the oxidant and the phase transfer agent is 100:(0.01-10):(0.001-5) to obtain the mixed glue ;

[0028] Wherein, the butyl rubber solution is a non-polar or weakly polar organic solution of butyl rubber, and the non-polar or weakly polar organic solvent used is C5~C30 straight chain alkane, branched chain alkane or cyclic alkane Alkanes or their mixtures, the concentration of the butyl rubber solution is any value between 10wt% and 25wt%. The mass ratio of butyl rubber to weak polar or non-polar alkane is any value in (11-35):100,

[0029] After obtaining the butyl rubber solution, add an oxidizing agent and a phase transfer agent to the butyl rubber solution and ...

Embodiment 1

[0050] (1) Configure 20kg of 20% butyl rubber glue, (Mooney 35, 1.7% unsaturation), 2.5kg of 5% bromine-n-hexane solution, 200g of 30% hydrogen peroxide solution, an appropriate amount of 2% sodium hydroxide solution, Phase transfer agent tetradecyltrimethylammonium chloride.

[0051] (2) Add 0.4% dry glue mass oxidant solution, 0.1% dry glue mass phase transfer agent and a small amount of distilled water to the glue solution to control the water content of the system to about 1%.

[0052] (3) Control the flow rate of glue solution at 200ml / min and bromine solution at 28ml / min.

[0053] (4) control 45 ℃ in the bromination reaction still, rotating speed 300rpm, at this moment, the residence time in the still is about 9min, control and neutralize 45 ℃ in the reaction still, rotating speed 300rpm, this moment material stays about 5min, the reaction system after the lye neutralization pH is 7-10

[0054] (5) Add 2.2%, 1.3%, 0.1% calcium stearate, epoxidized soybean oil, and anti...

Embodiment 2

[0056] (1) Prepare 20kg of 15% butyl rubber glue (Mooney 35, 1.7% unsaturation), 2kg of 5% bromine-n-hexane solution, and an appropriate amount of 2% sodium hydroxide solution, prepare solid sodium hypochlorite, phase transfer agent three Butylamine.

[0057] (2) Add sodium hypochlorite with 0.1% dry glue mass, phase transfer agent with 0.15% dry glue mass and a small amount of distilled water to the glue solution, and control the water content of the system to about 0.5%.

[0058] (3) Control the flow rate of glue solution at 190ml / min and bromine solution at 18ml / min.

[0059] (4) control 50 ℃ in bromination reaction kettle, rotating speed 300rpm, at this moment, the residence time in kettle is about 10min, control neutralization reaction kettle at 45 ℃, rotating speed 300rpm, material stays about 5min now, and the system is neutral.

[0060] (5) Add 2.2%, 1.3%, 0.1% calcium stearate, epoxidized soybean oil, and antioxidant 1076 to the neutralized glue solution after drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com