Sucralfate oral preparation and preparation method thereof

An oral preparation, sucralfate technology, applied in the field of oral sucralfate preparation and its preparation, can solve the problems of limitation, low bioavailability, unsatisfactory treatment effect, etc., achieve good gastric retention characteristics, prolong the repair of ulcers, product Stable and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

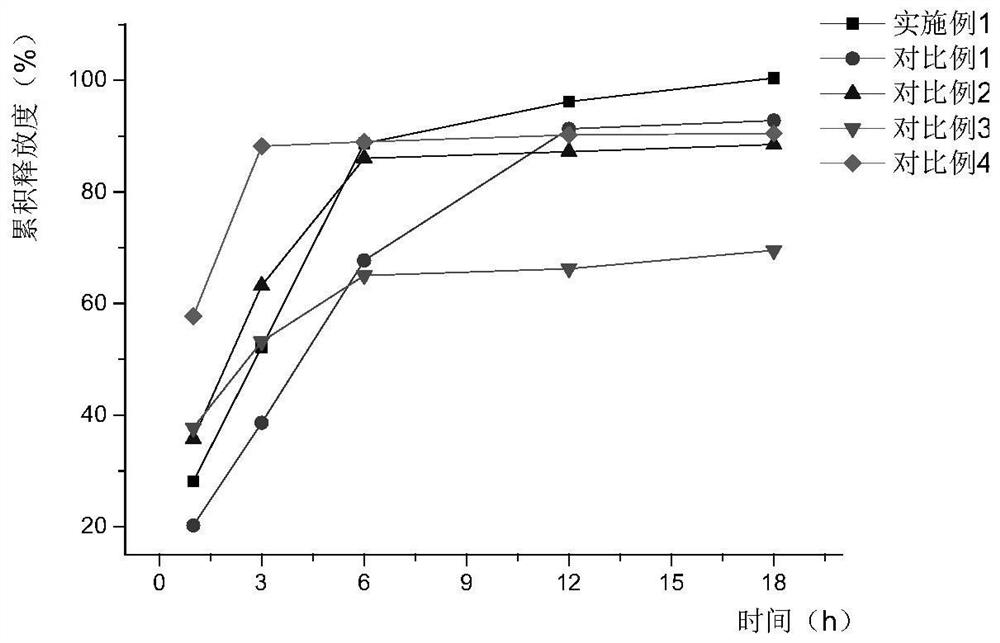

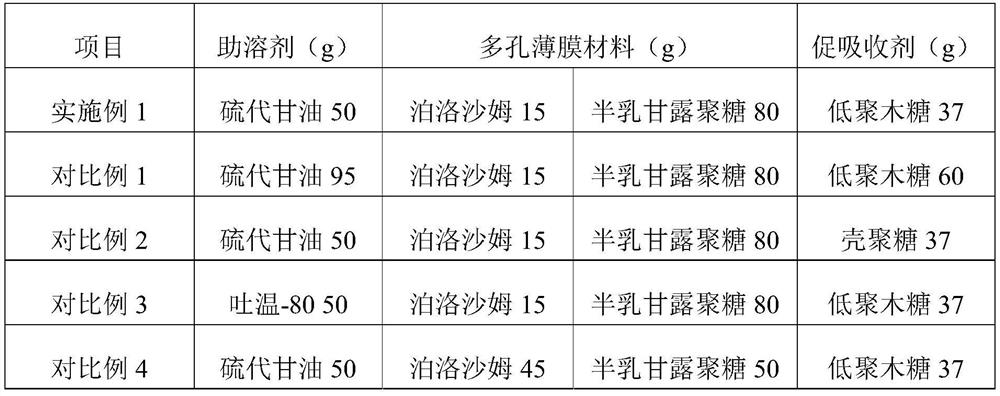

Examples

Embodiment 1

[0029] A sucralfate oral preparation, the prescription is as follows:

[0030] serial number Material composition Proportion (g) 1 Sucralfate 350 2 sucrose 250 3 Mannitol 150 4 Porous starch 50 5 Sodium carboxymethyl cellulose Moderate 6 peppermint 7.4 7 orange essence Moderate 8 Thioglycerol 50 9 Poloxamer 15 10 Galactomannan 80 11 xylo-oligosaccharide 37

[0031] (1) Preparation of raw materials: The porous film material is a mixture of poloxamer and galactomannan in a mass ratio of 0.3:1.6, and is irradiated with 630 nm red light to obtain a porous film material with a pore size of 1.0 μm.

[0032] (2) the preparation method of sucralfate oral preparation, comprises the steps:

[0033] Step S1: respectively pass sucralfate and diluent through 80 mesh sieves to obtain premix 1, and pass aromatic correctives through 100 mesh sieves to obtain premix 2;

[0034] Step S2: Add binder...

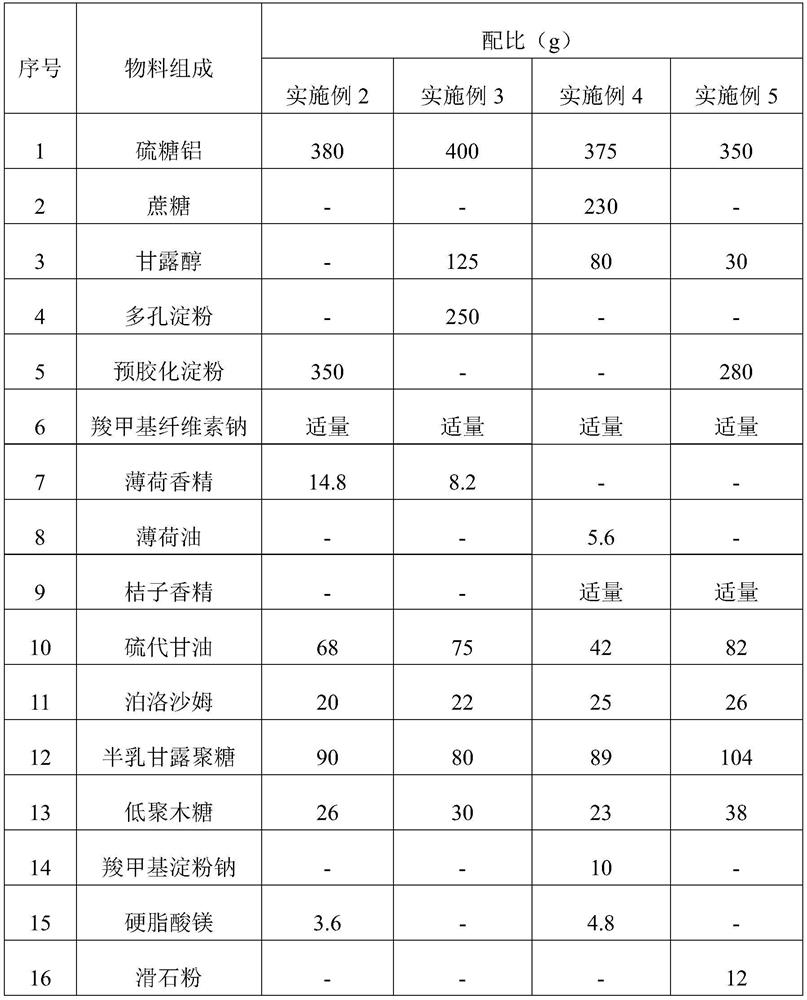

Embodiment 2-5

[0043] A sucralfate oral preparation, the prescription is as follows:

[0044]

[0045] (1) Preparation of raw materials: the porous film material is poloxamer and galactomannan irradiated with 630 nm red light to obtain a porous film material with a pore size of 1.0 μm.

[0046] (2) the preparation method of above-mentioned embodiment 2-5 sucralfate oral preparation, comprises the steps:

[0047] Step S1: respectively pass sucralfate and diluent through 80 mesh sieves to obtain premix 1, and pass aromatic correctives through 100 mesh sieves to obtain premix 2;

[0048] Step S2: Add binder and absorbent to premix 1, make soft material, add cosolvent and porous film material, stir at 25°C for 30min, sonicate at 700W for 40min, pass through a 20-mesh sieve, granulate at 50 ℃ drying to moisture content ≤ 3.0% to obtain particulate matter;

[0049] Step S301: take the granules, pass through a 20-mesh sieve, granulate, add premix 2, sodium carboxymethyl starch and magnesium stea...

Embodiment 6

[0057] The difference between this example and Example 1 is that the preparation methods of oral sucralfate preparations are different, and the specific steps are:

[0058] Step S1: respectively pass sucralfate and diluent through a 70-mesh sieve to obtain premix 1, and pass the aromatic correctives through a 100-mesh sieve to obtain premix 2;

[0059] Step S2: Add binder and absorbent to premix 1, make soft material, add cosolvent and porous film material, stir at 25°C for 30min, 800W ultrasonic for 60min, pass through a 20-mesh sieve, granulate at 50 ℃ drying to moisture content ≤ 3.0% to obtain particulate matter;

[0060] Step S3: take the granules, pass through a 20-mesh sieve, granulate, add premix 2, sodium carboxymethyl starch and magnesium stearate, mix, and press with a 9mm diameter flat arc punch to obtain a sucralfate oral preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com