Modified polyphenylsulfone filtering membrane applied to arsenic removal and preparation method thereof

A polyphenylsulfone and filter membrane technology, applied in the field of modified polyphenylsulfone filter membrane and its preparation, can solve problems such as unsatisfactory arsenic removal effect, and achieve the effects of excellent adsorption capacity, enhanced hydrophilicity, and improved agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

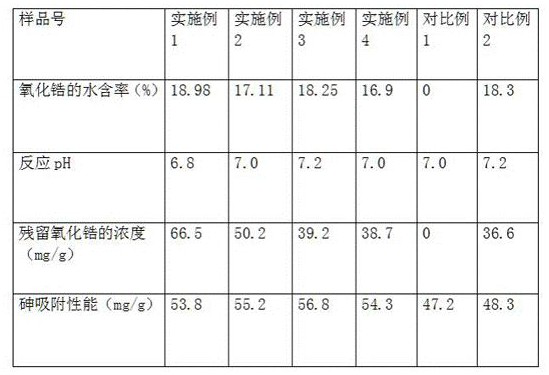

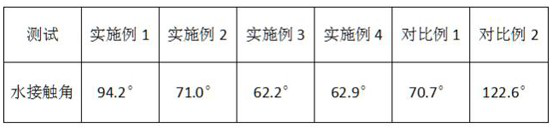

Examples

Embodiment 1

[0048]A preparation method of a modified polyphenylsulfone filter membrane applied to arsenic removal is as follows:

[0049] 1. Preparation of acyl chloride polyethylene glycol modified nano-silica loaded with zirconia

[0050] (1) In a nitrogen atmosphere, add nano-silica (15g) and toluene diisocyanate (10g) to a toluene solution (100ML), and stir at room temperature to react to obtain isocyanated nano-silica, and ultrasonically disperse until uniform; Polyethylene glycol (800 ml) was added, and the modification reaction was carried out at 100 °C for 12 h. The solvent was distilled off under reduced pressure, and the solid product was washed with distilled water and acetone to obtain polyethylene glycol-modified nano-silica; in a nitrogen atmosphere, polyethylene glycol-modified nano-silica was added to the N,N-dimethylformamide solution. Silica (100g), maleic anhydride (50g) and catalyst pyridine (5g) were esterified at 180°C for 10h. After the reaction was completed, it w...

Embodiment 2

[0057] A preparation method of a modified polyphenylsulfone filter membrane applied to arsenic removal is as follows:

[0058] 1. Preparation of acyl chloride polyethylene glycol modified nano-silica loaded with zirconia

[0059] (1) In a nitrogen atmosphere, add nano-silica (15g) and toluene diisocyanate (10g) to a toluene solution (100ML), and stir at room temperature to react to obtain isocyanated nano-silica, and ultrasonically disperse until uniform; Polyethylene glycol (800 ml) was added, and the modification reaction was carried out at 100 °C for 12 h. The solvent was distilled off under reduced pressure, and the solid product was washed with distilled water and acetone to obtain polyethylene glycol-modified nano-silica; in a nitrogen atmosphere, polyethylene glycol-modified nano-silica was added to the N,N-dimethylformamide solution. Silica (100g), maleic anhydride (50g) and catalyst pyridine (5g) were esterified at 180°C for 10h. After the reaction was completed, it ...

Embodiment 3

[0066] A preparation method of a modified polyphenylsulfone filter membrane applied to arsenic removal is as follows:

[0067] 1. Preparation of acyl chloride polyethylene glycol modified nano-silica loaded with zirconia

[0068] (1) In a nitrogen atmosphere, add nano-silica (15g) and toluene diisocyanate (10g) to a toluene solution (100ML), and stir at room temperature to react to obtain isocyanated nano-silica, and ultrasonically disperse until uniform; Polyethylene glycol (800 ml) was added, and the modification reaction was carried out at 100 °C for 12 h. The solvent was distilled off under reduced pressure, and the solid product was washed with distilled water and acetone to obtain polyethylene glycol-modified nano-silica; in a nitrogen atmosphere, polyethylene glycol-modified nano-silica was added to the N,N-dimethylformamide solution. Silica (100g), maleic anhydride (50g) and catalyst pyridine (5g) were esterified at 180°C for 10h. After the reaction was completed, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com